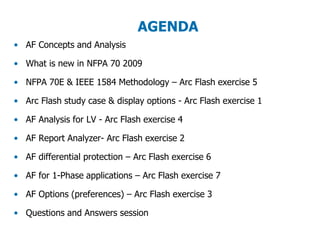

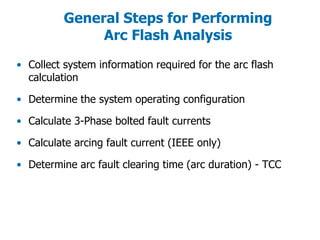

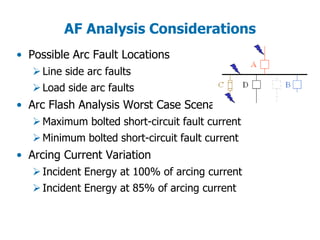

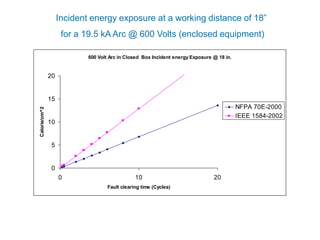

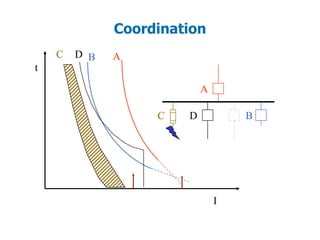

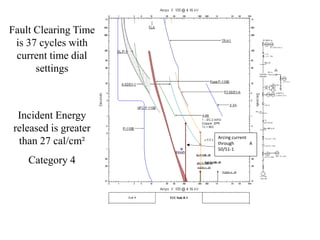

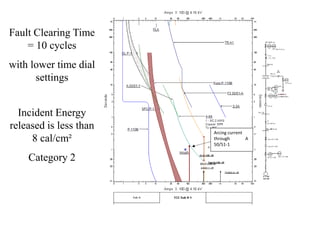

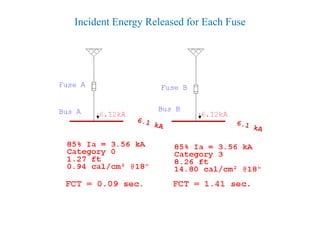

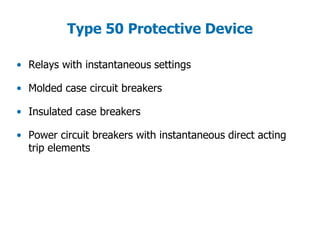

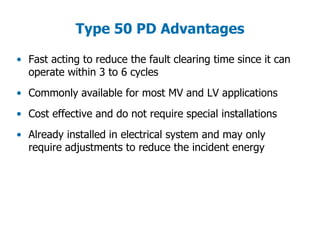

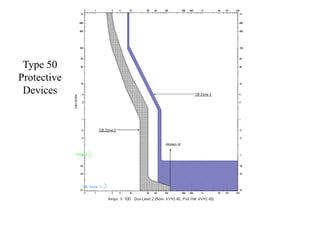

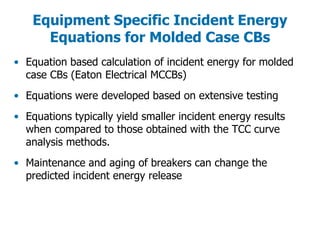

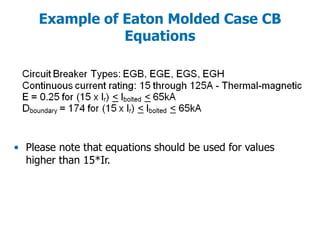

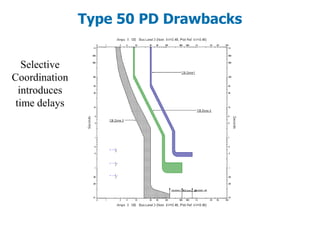

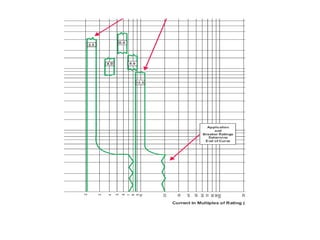

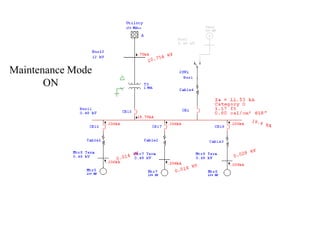

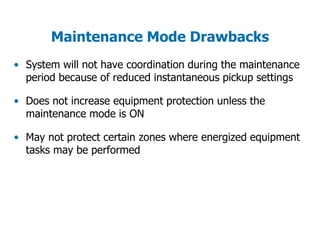

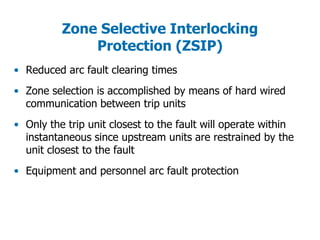

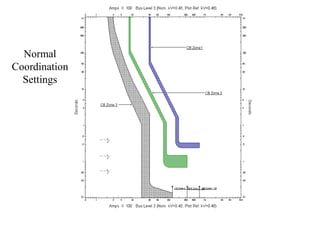

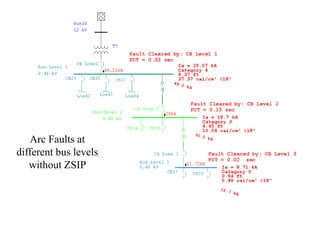

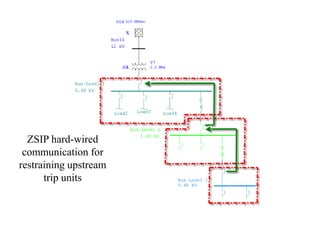

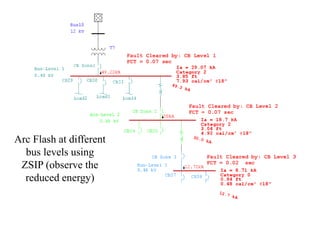

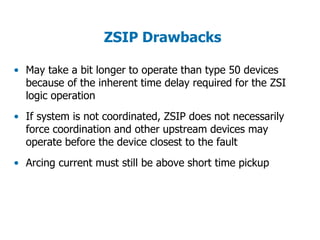

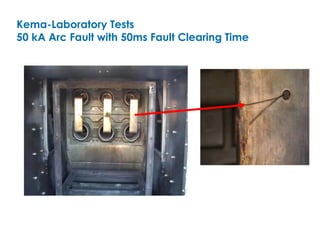

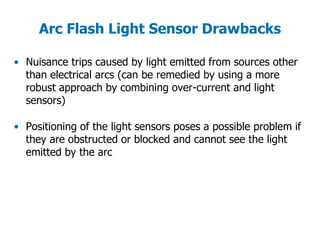

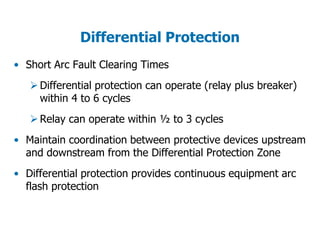

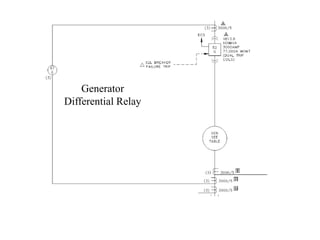

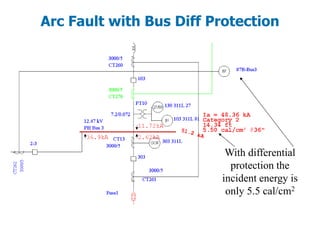

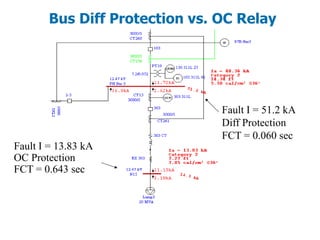

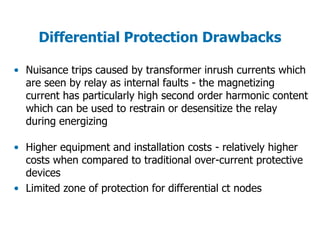

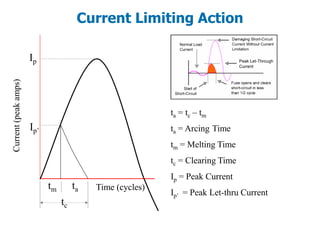

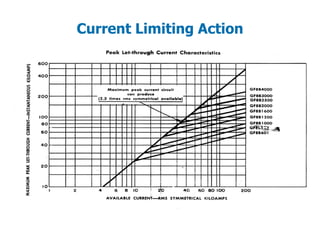

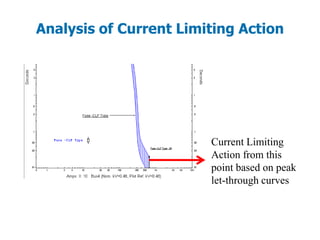

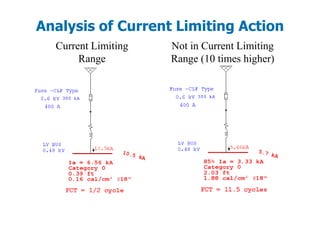

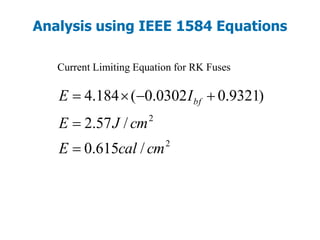

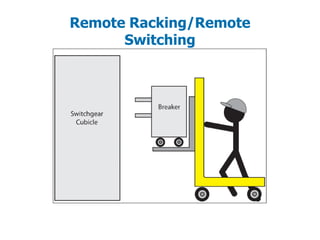

This document provides an overview of arc flash analysis and mitigation methods. It discusses the general steps for performing arc flash analysis according to IEEE 1584 and NFPA 70E standards. It then describes various analysis considerations and how to analyze arc flash results. The document outlines several methods that can be used to mitigate incident energy, including reducing fault clearing time, increasing working distance, reducing short-circuit current, and reducing energy exposure. It provides examples and drawbacks for each mitigation method.