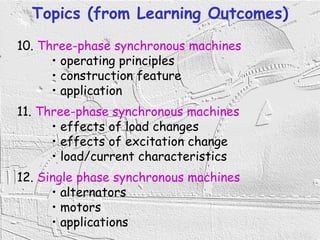

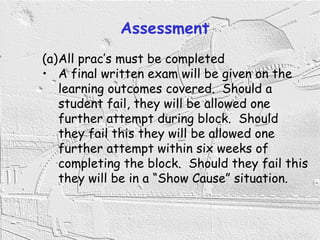

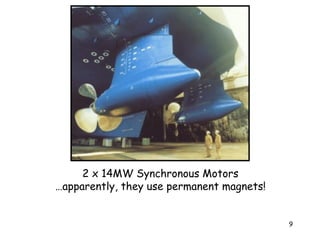

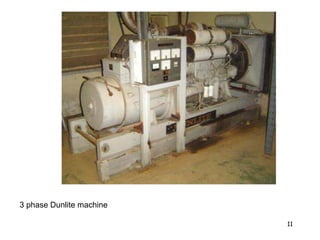

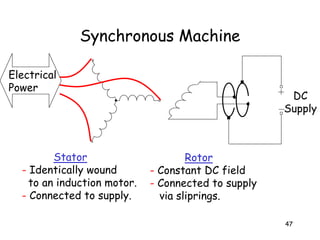

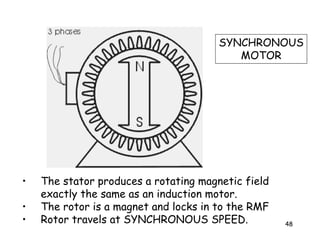

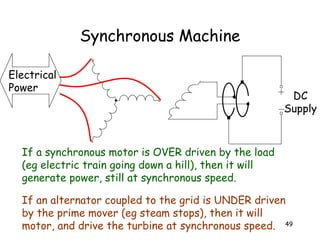

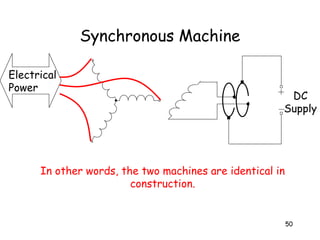

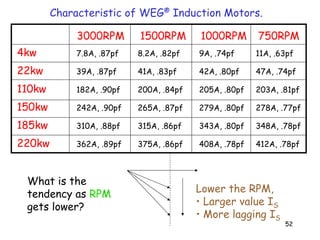

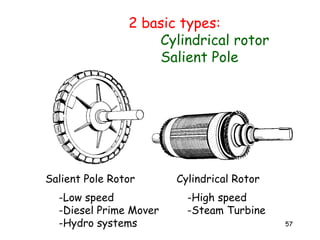

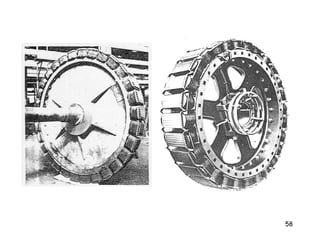

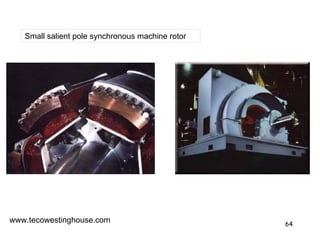

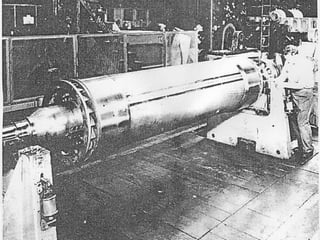

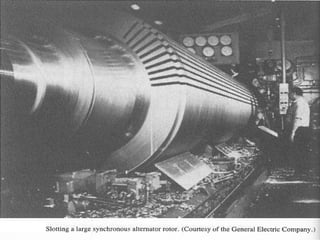

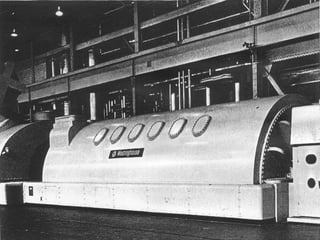

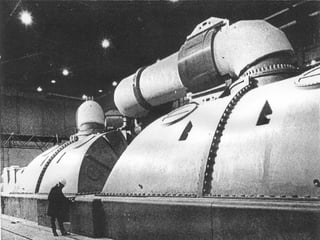

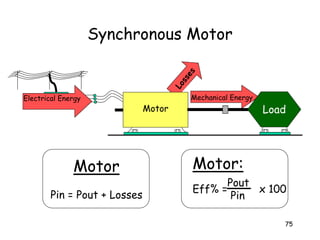

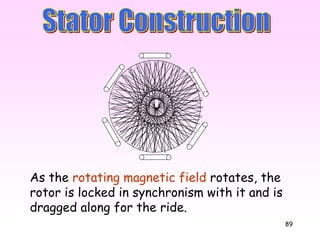

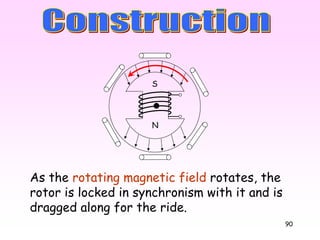

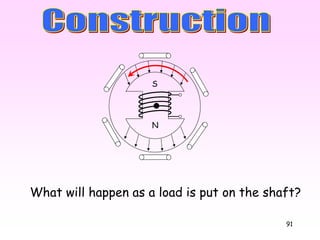

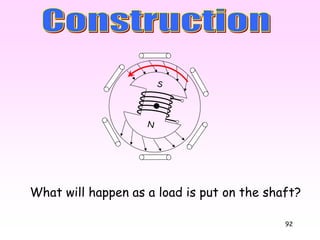

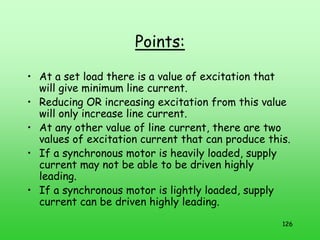

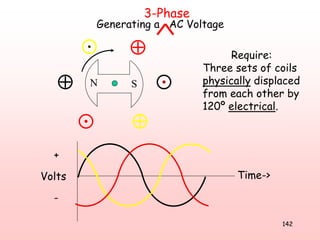

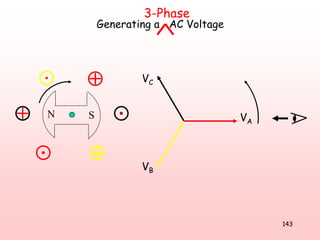

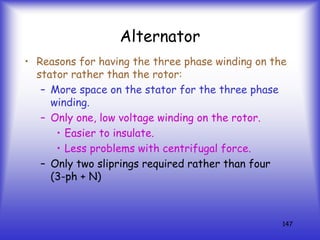

This document outlines classroom rules for a class, including that students must listen when the teacher talks, certain items are not allowed like phones or sleeping, and provides contact information for the teacher. It also lists topics to be covered in the class, including three-phase synchronous machines, their operating principles, construction features and applications. Finally, it discusses assessment requirements, including that all practical assignments must be completed and details around exams and resits.