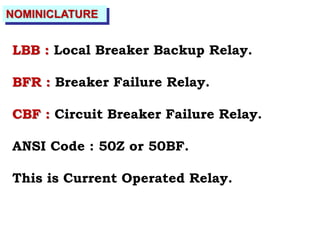

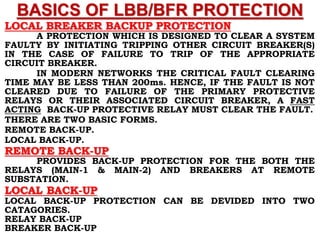

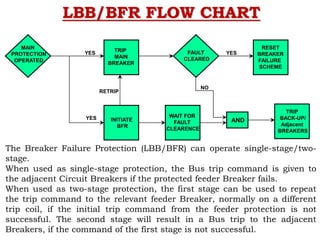

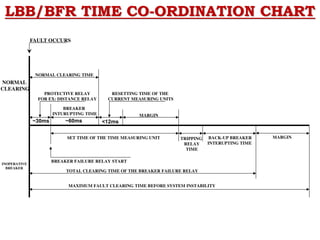

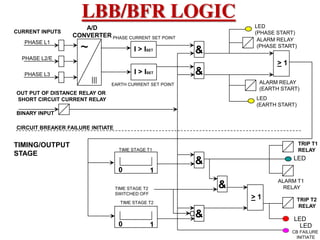

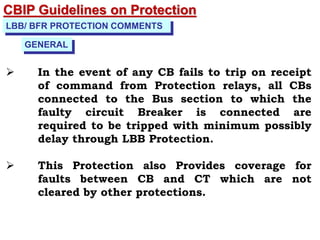

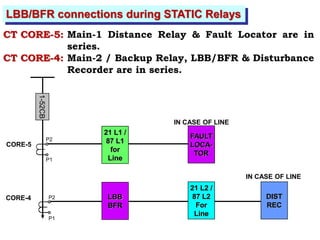

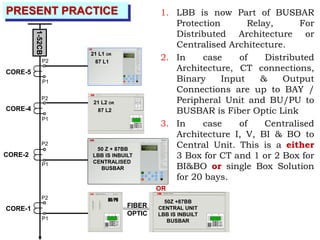

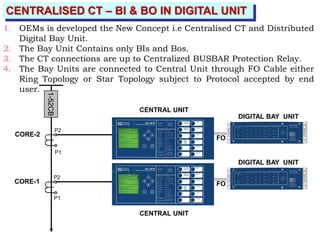

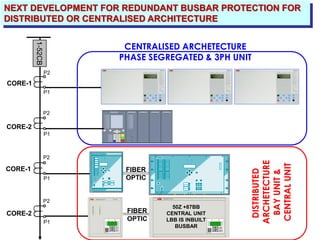

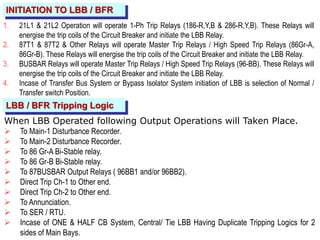

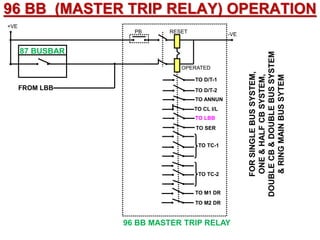

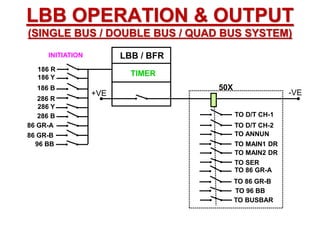

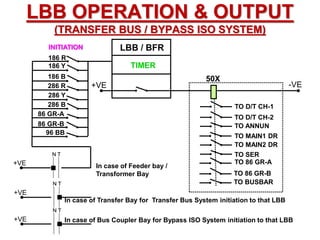

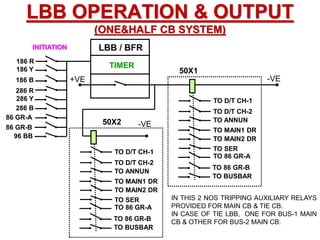

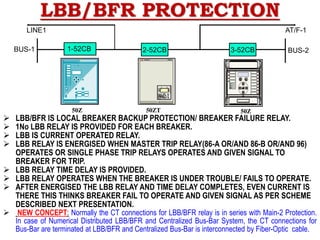

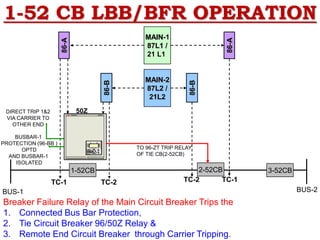

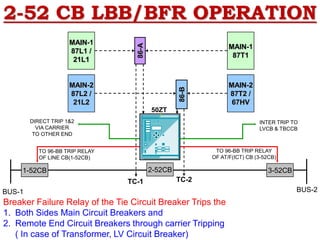

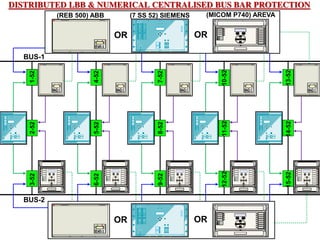

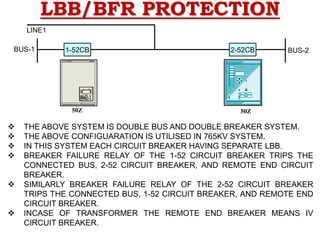

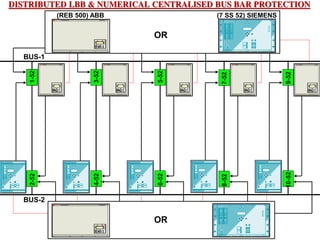

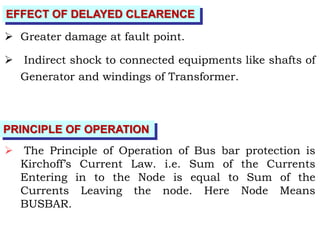

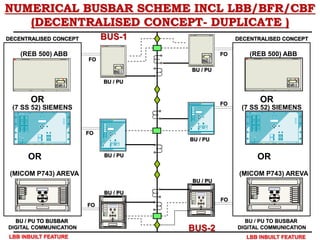

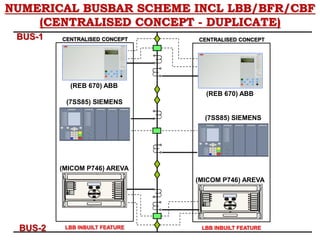

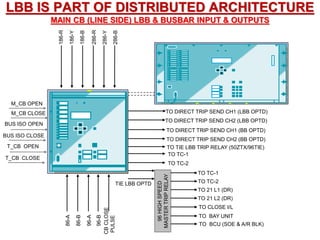

This document provides information about local breaker backup (LBB) and breaker failure relay (BFR) protection. It discusses the basics of LBB/BFR protection including definitions, applications, and operation. It describes relay-based and breaker-based backup protection. The document includes diagrams of LBB/BFR logic, coordination, and connections for static and numerical relays. It provides guidelines on requirements, settings, and recommendations for implementing LBB/BFR protection.