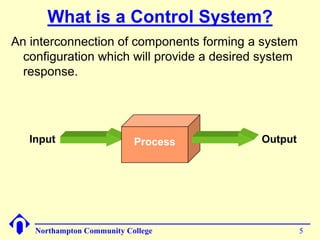

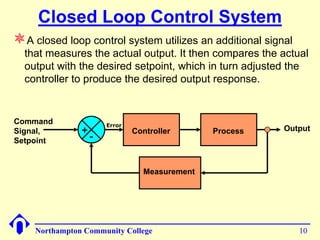

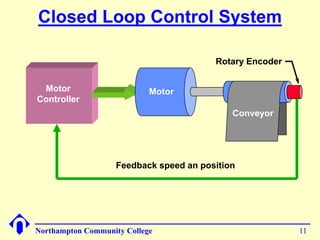

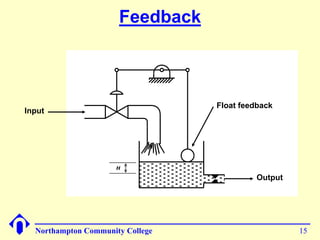

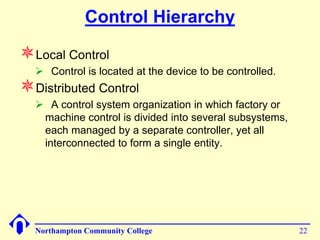

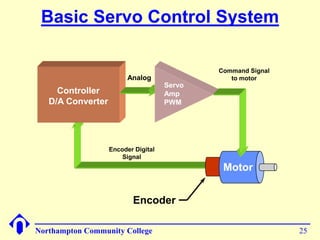

This document from Northampton Community College provides an overview of control systems basics. It defines key terms like control, controller, open loop and closed loop systems. It explains the main components of a control system including sensors, actuators and feedback. It also discusses different types of controllers, control classifications and factors that can affect control systems like disturbances. The document aims to introduce students to the fundamental concepts and components of industrial control systems.