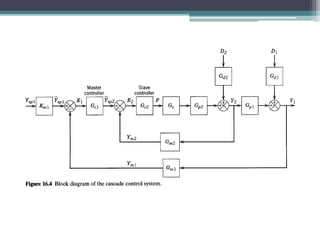

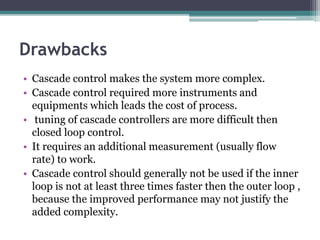

This document discusses cascade control systems. It defines cascade control as using two closed loop controllers where the output of the first controller is the set point of the second. The first loop is called the master controller and the second the slave controller. Cascade control provides more precise control of processes with multiple stages. It allows compensation for load changes and helps maintain desired values. The document outlines applications in steam power plants including drum level control and steam temperature control. It notes both advantages like improved dynamics but also drawbacks like increased complexity and cost.