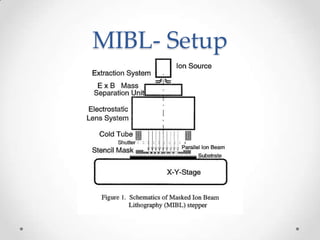

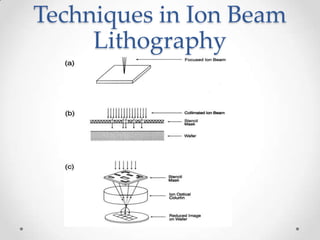

This document discusses masked ion beam lithography (MIBL), which uses a focused ion beam to pattern biomaterials. MIBL allows for selective patterning without multiple processing steps like photolithography. Common ion sources for MIBL include ions of calcium, magnesium, sodium, and phosphorus. The setup involves an ion source, mass separation unit, and electrostatic system to produce a parallel ion beam, along with a cooled mask and substrate. MIBL has applications in nanofabrication, circuit editing, and biomaterial patterning without complex processing. Its advantages over other techniques include reduced steps, tailored surface chemistry, and independent patterning of material strength and composition.