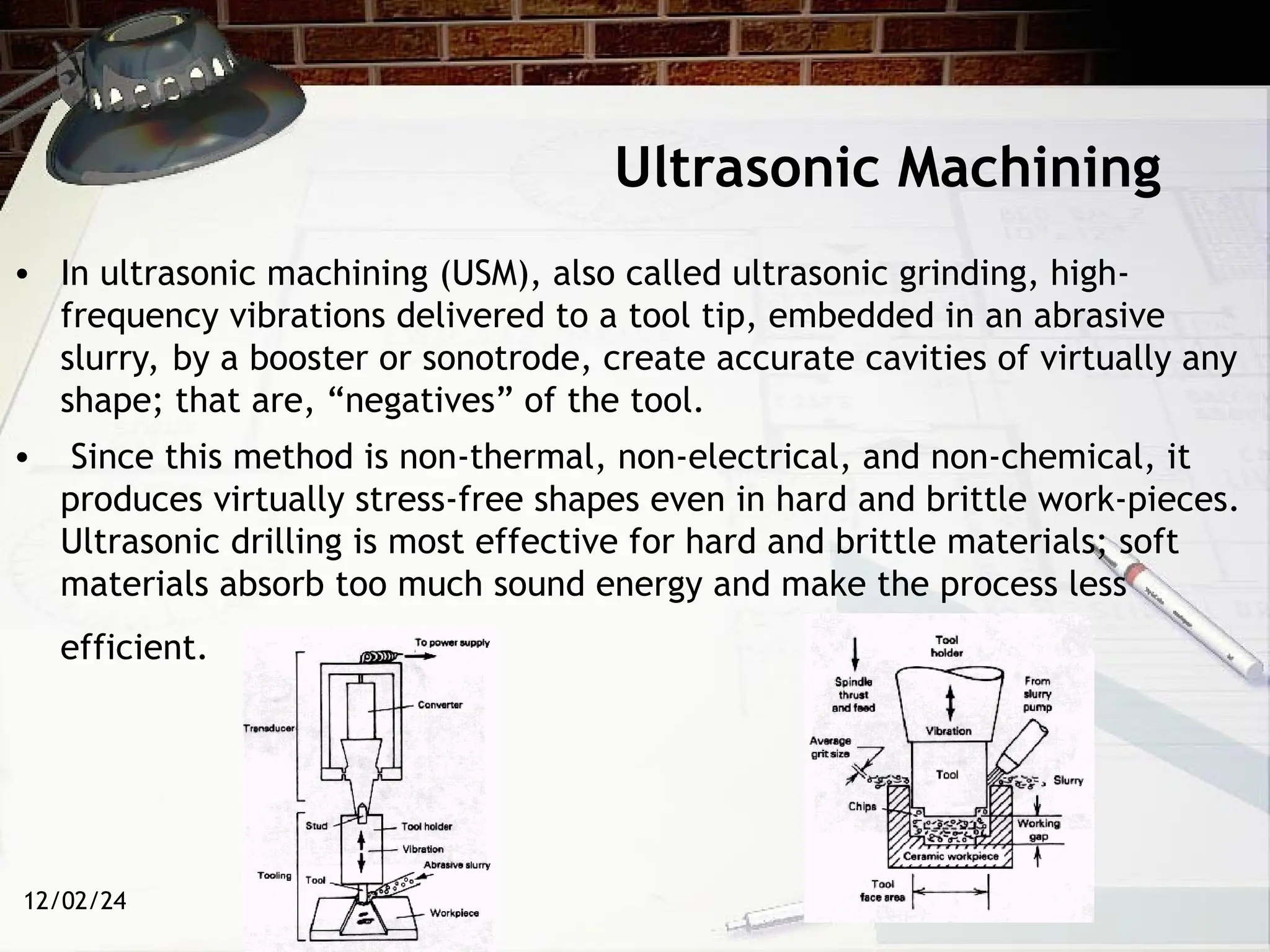

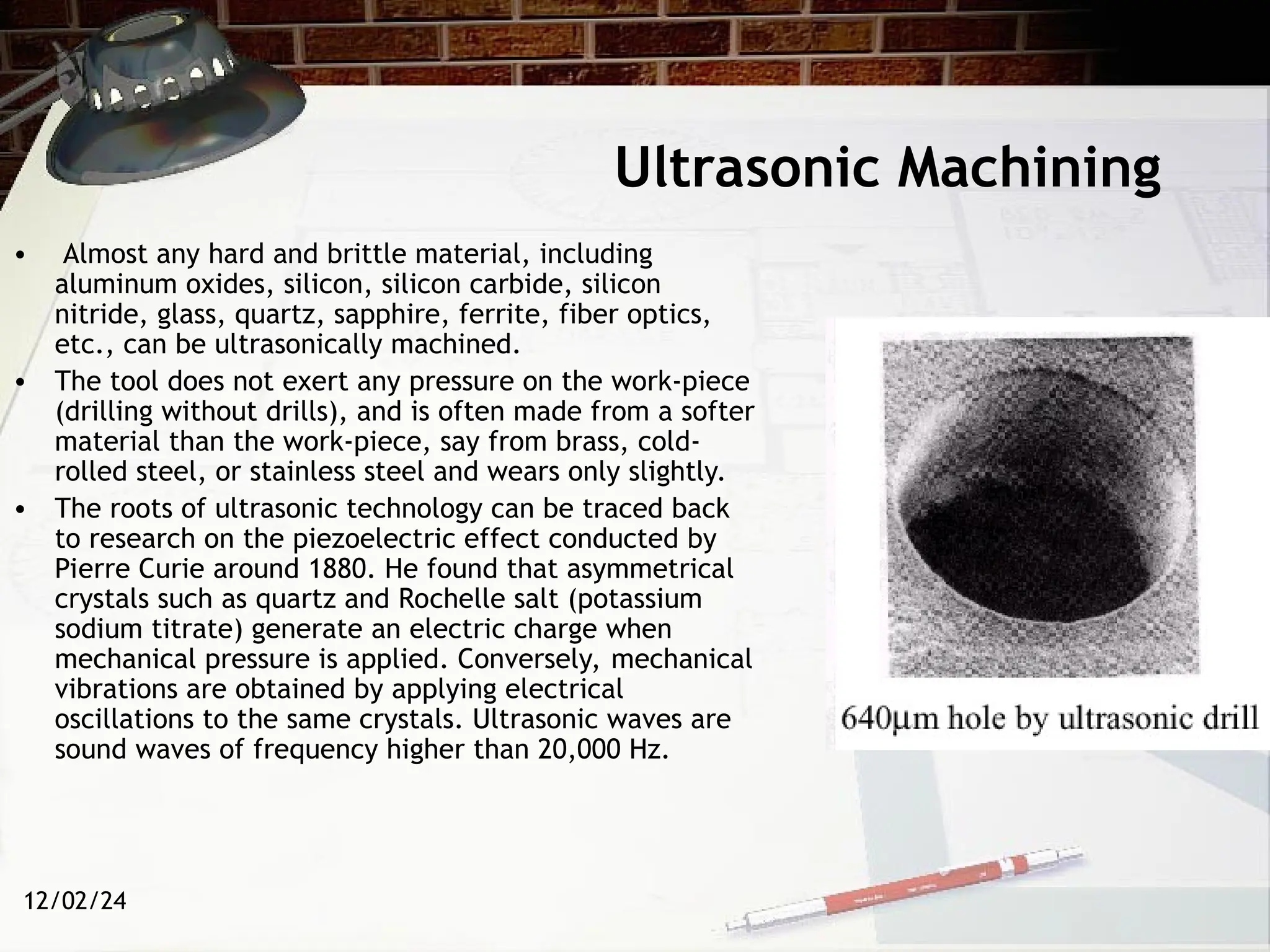

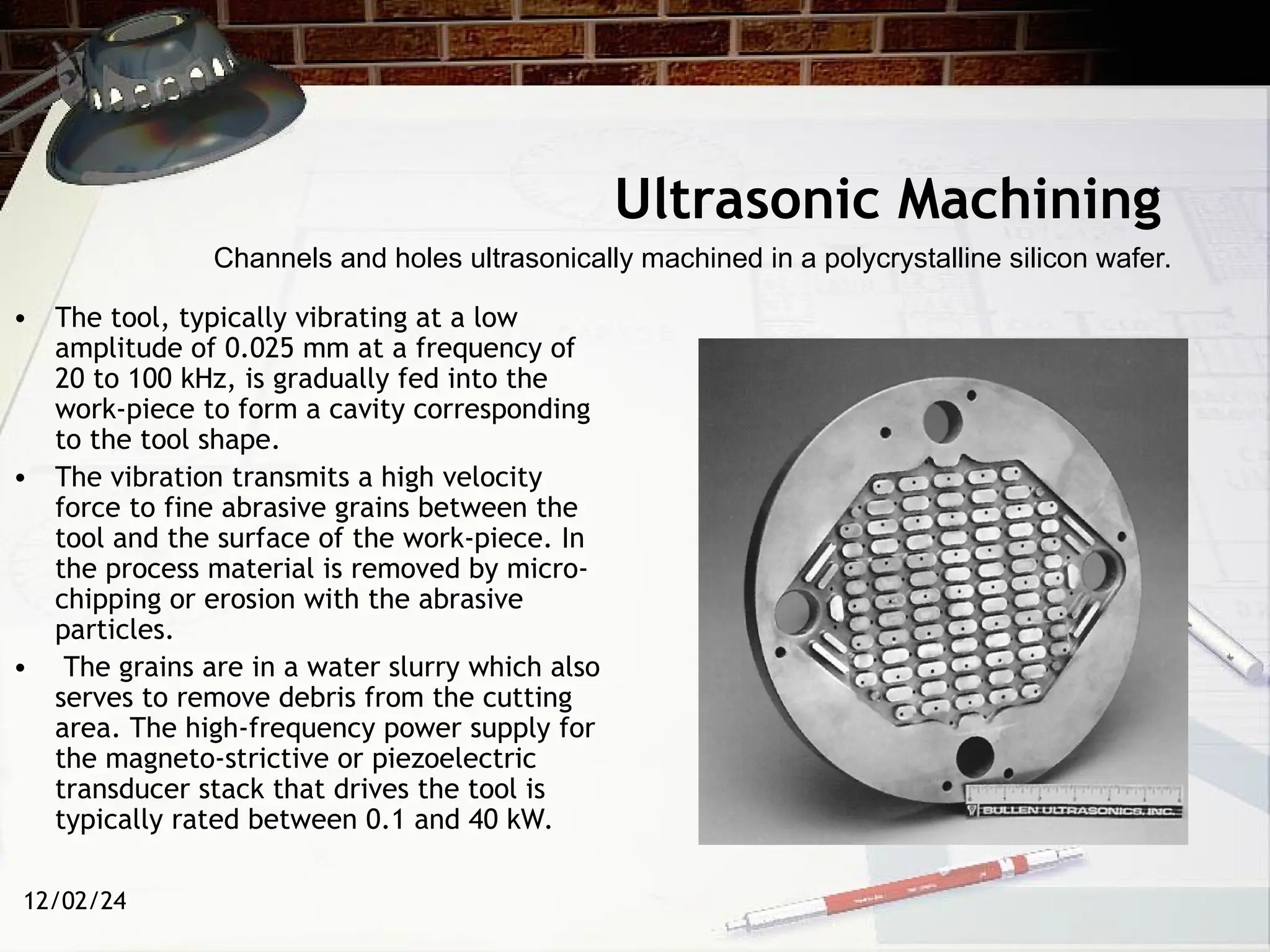

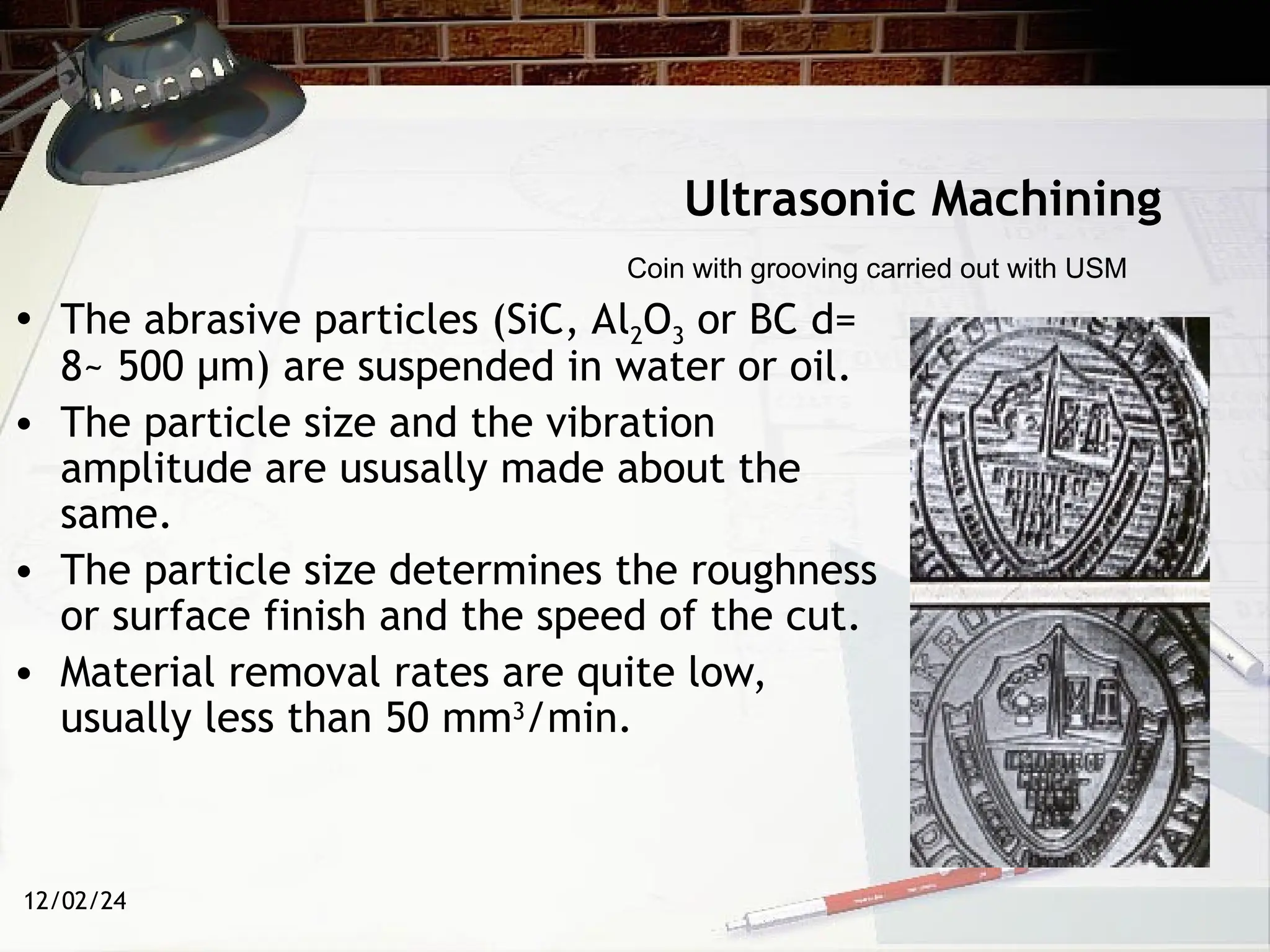

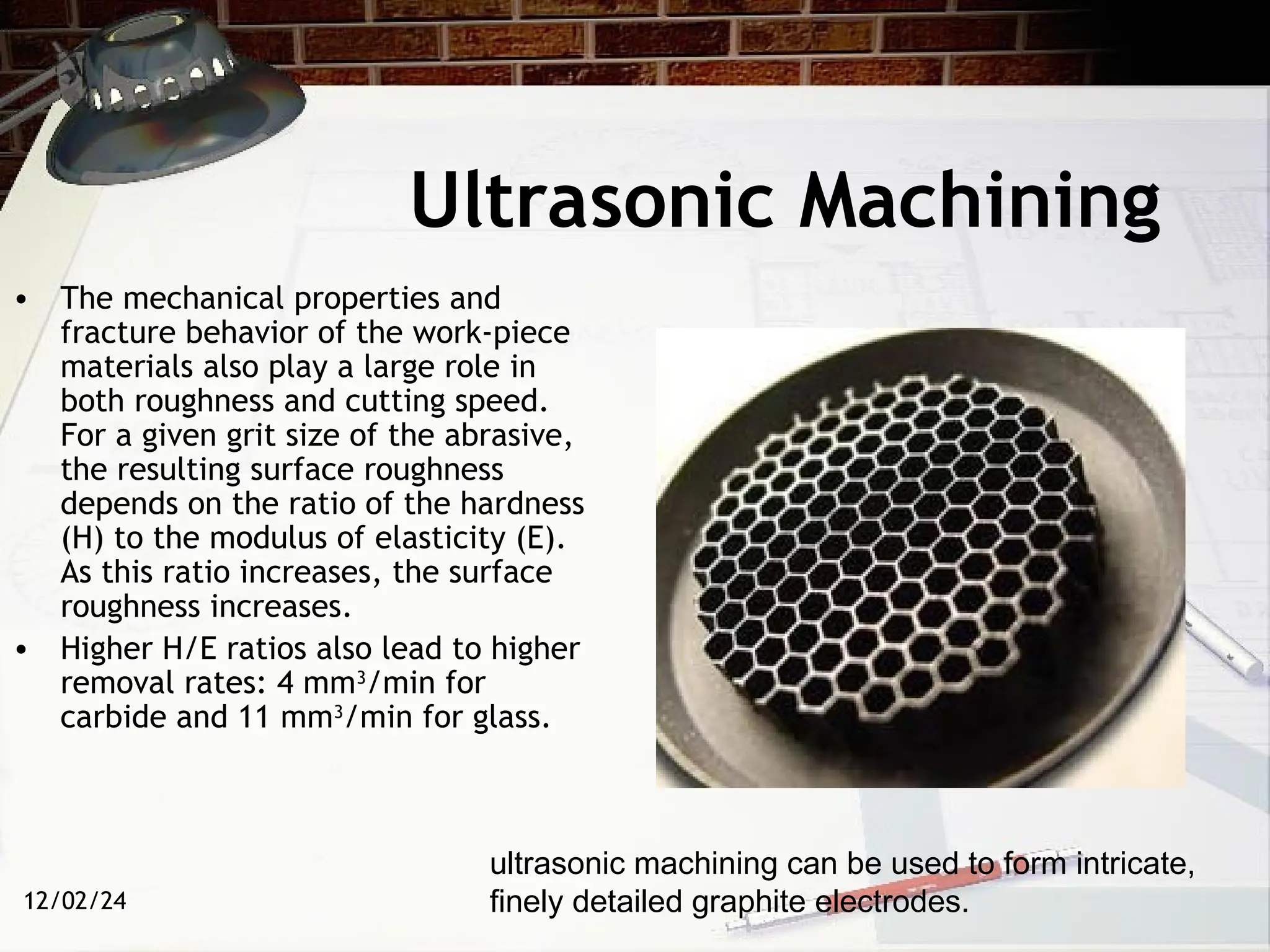

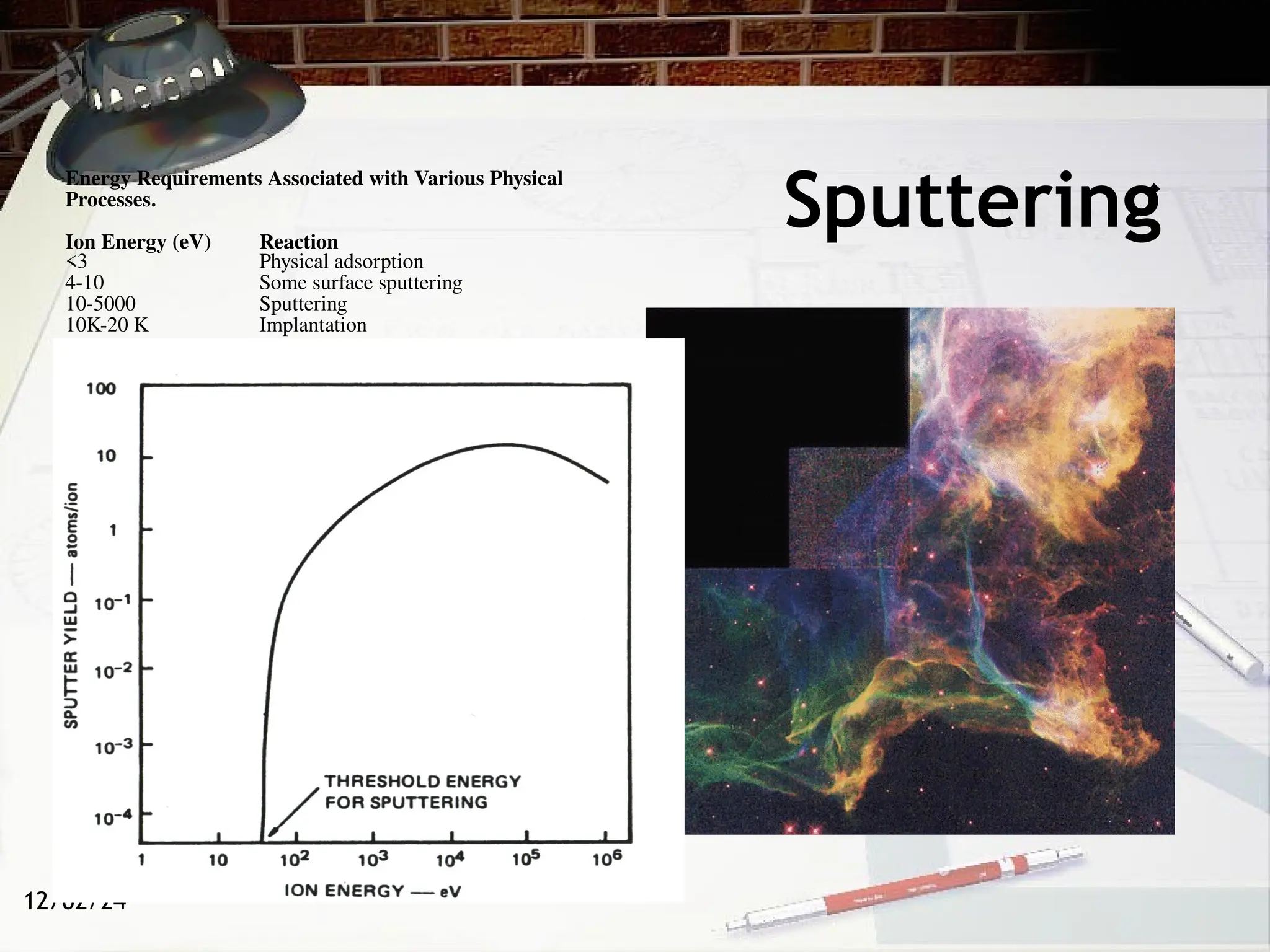

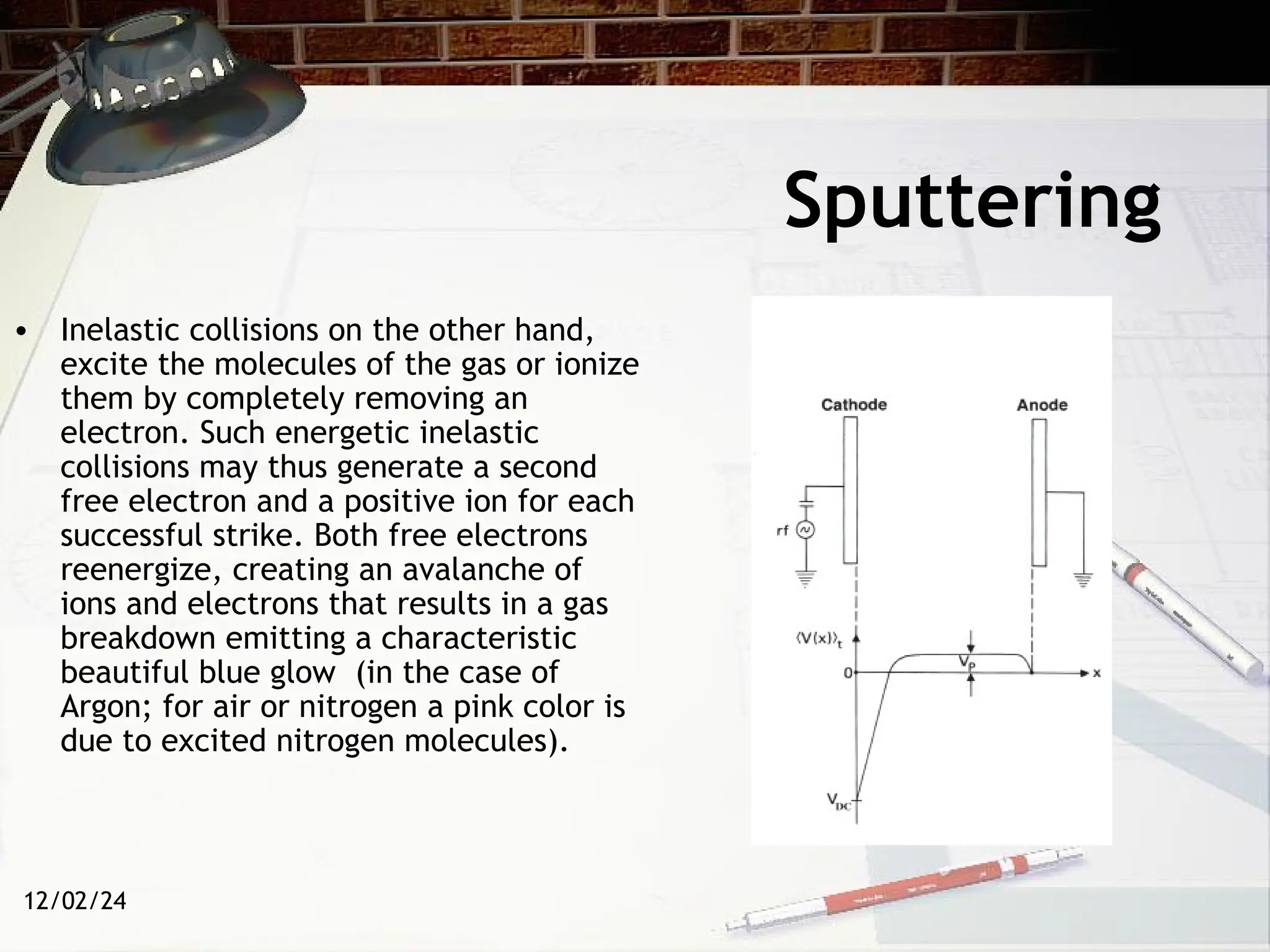

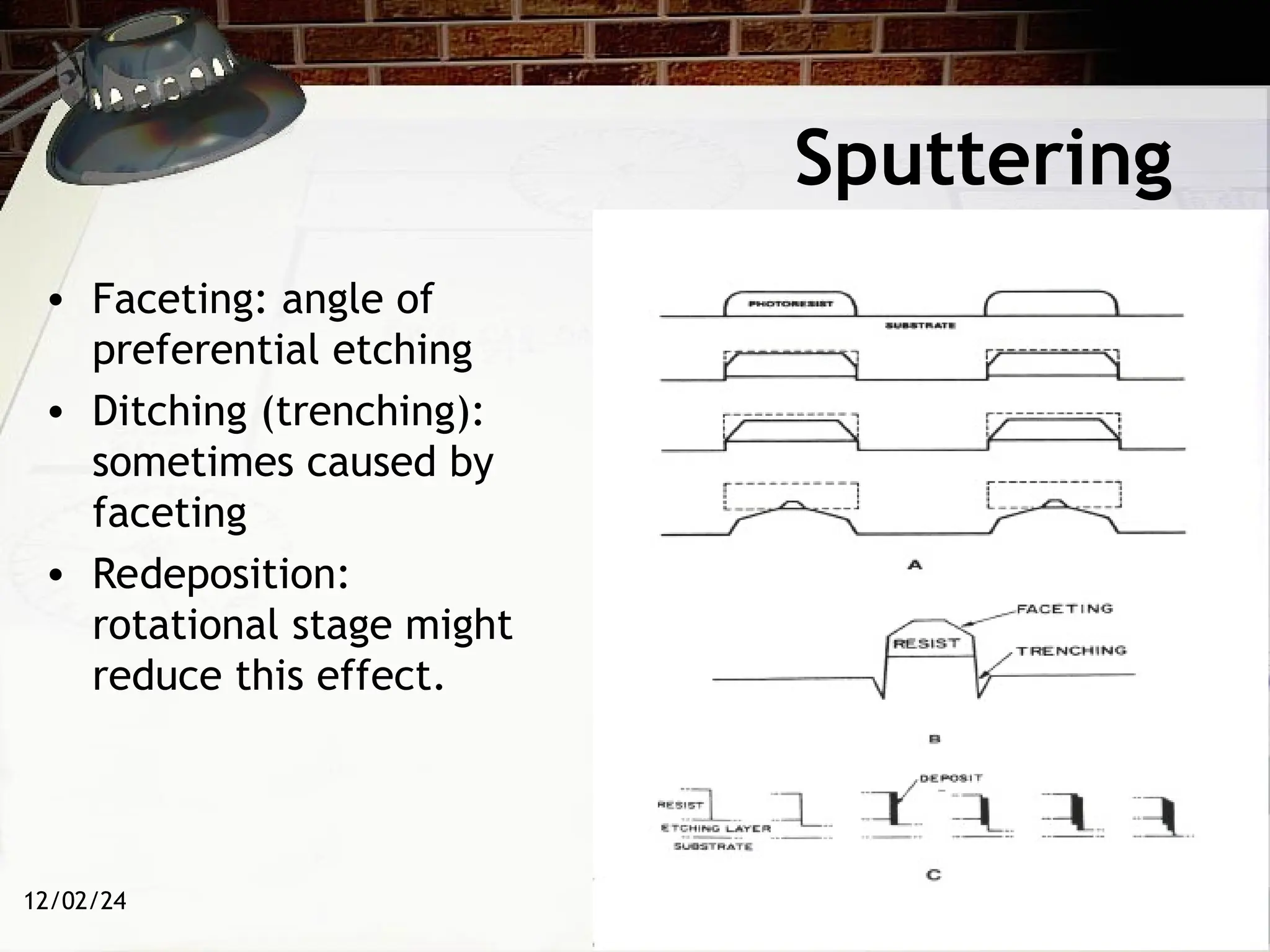

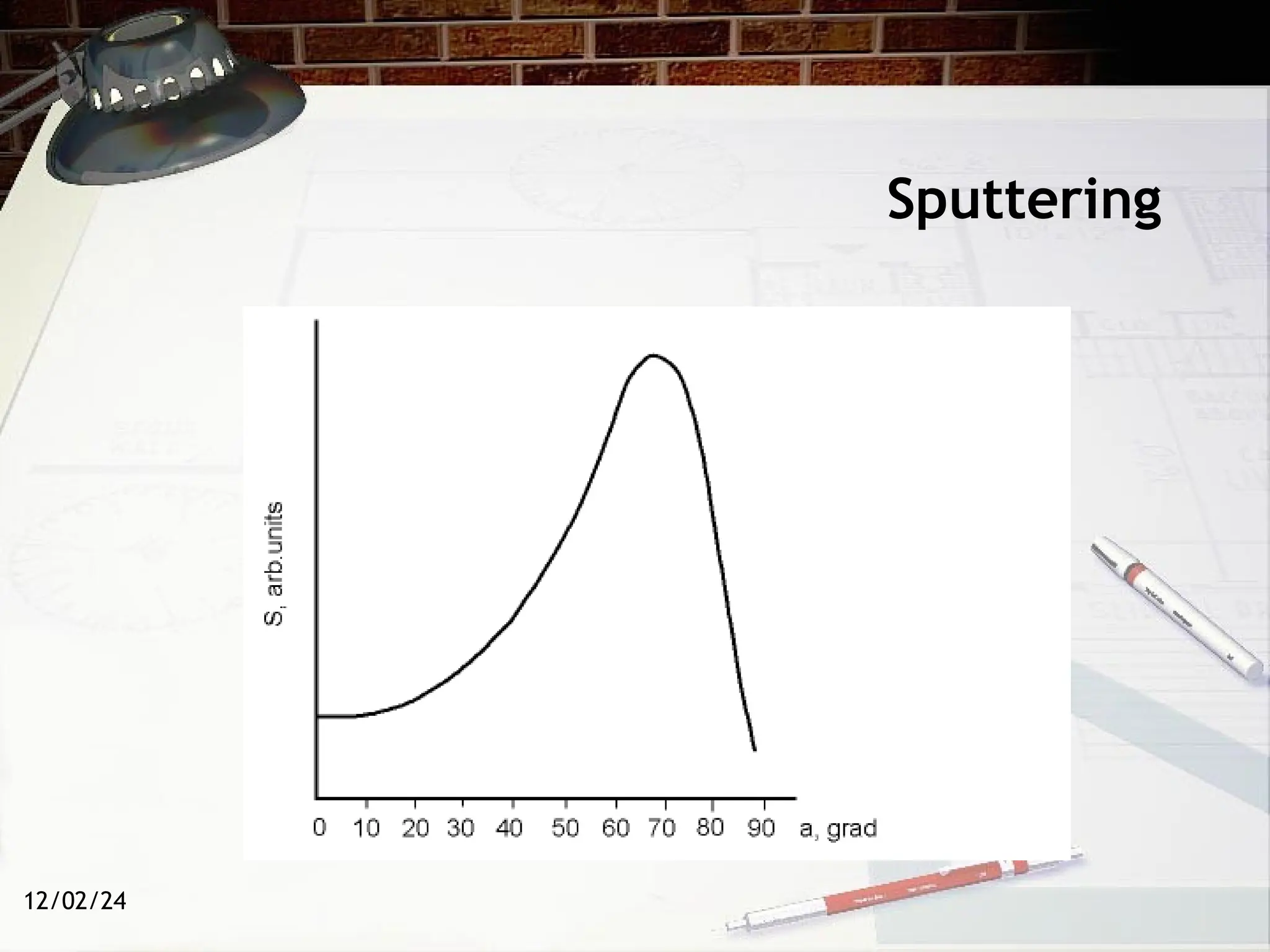

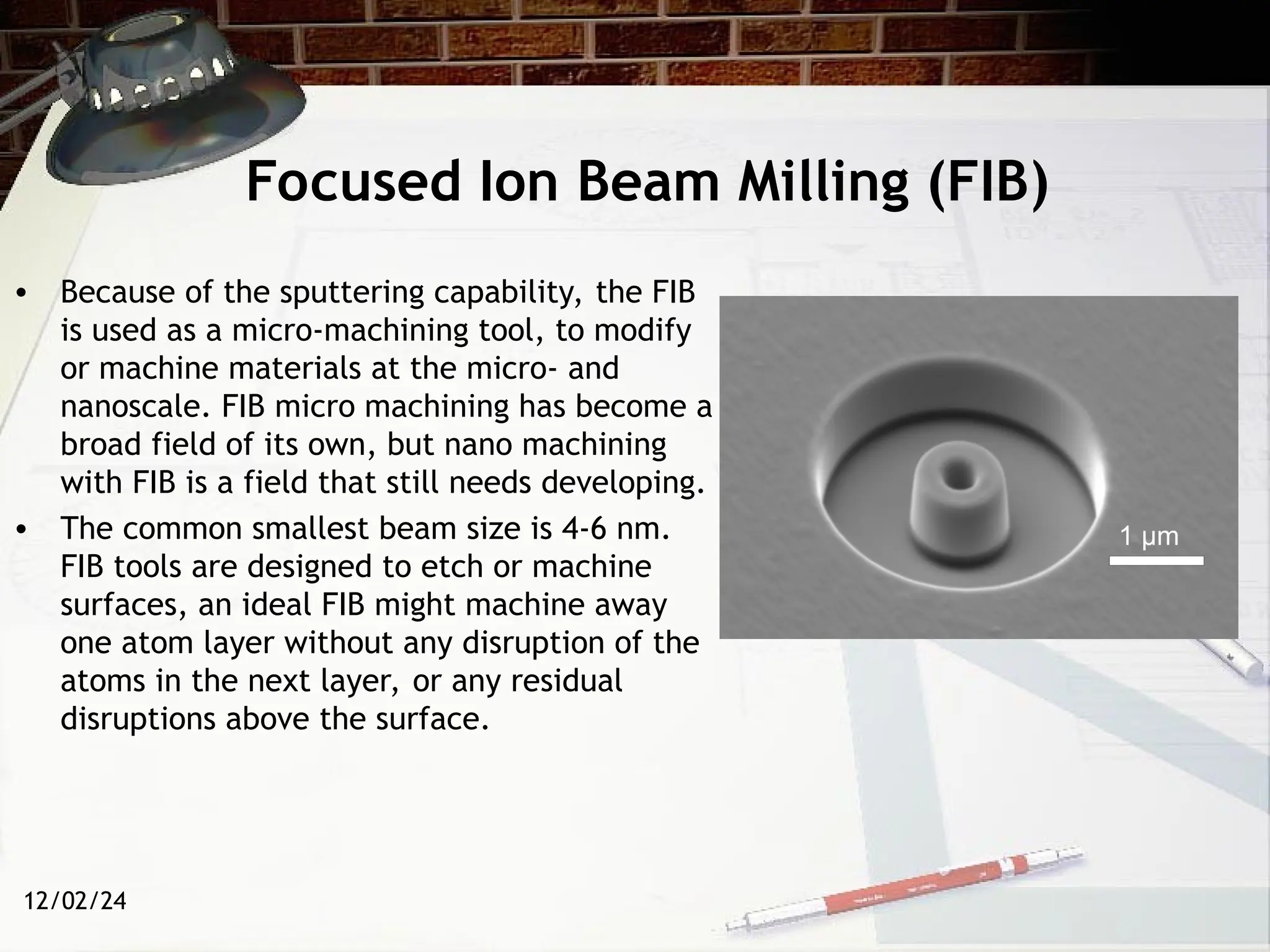

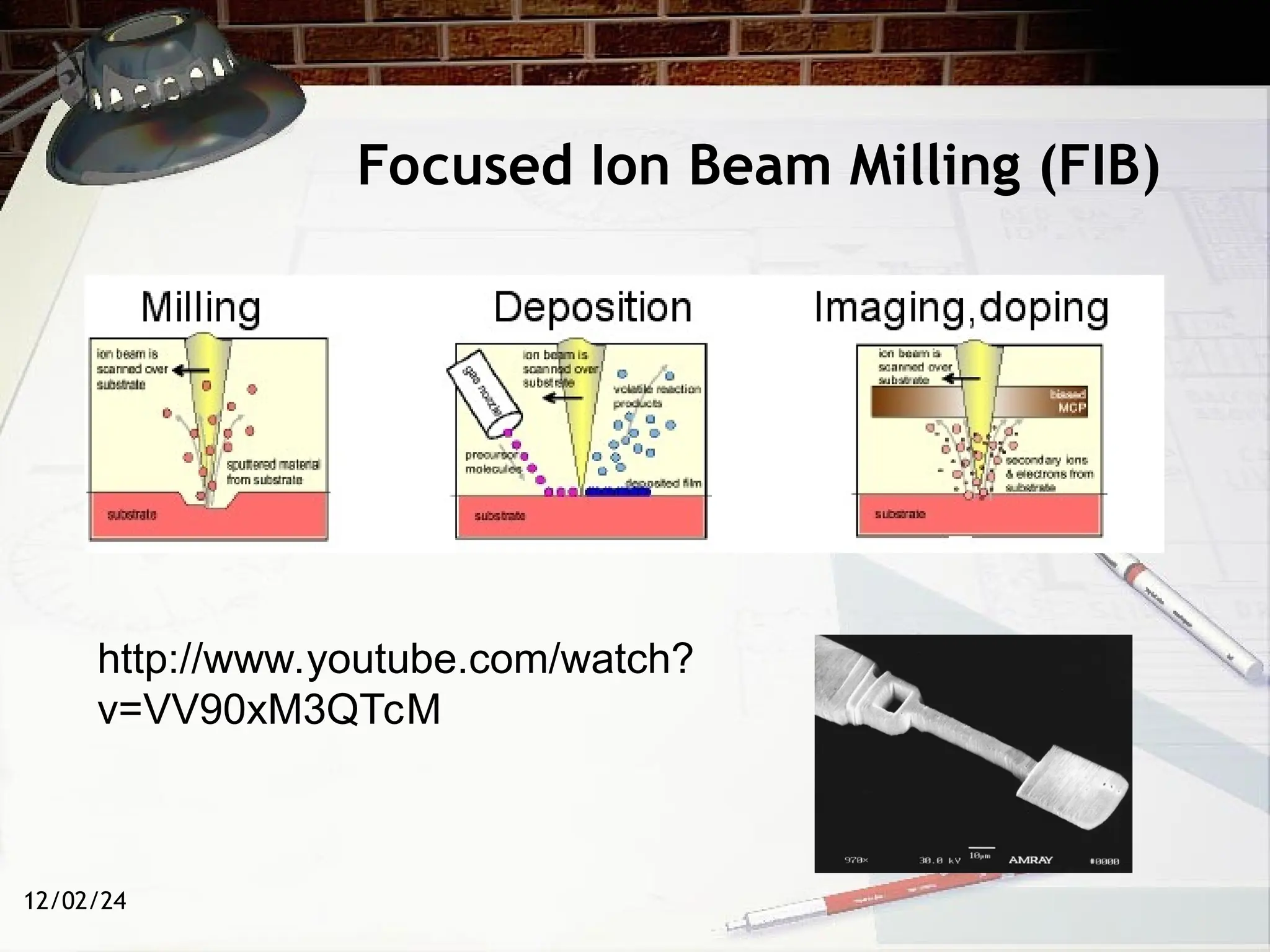

The document details advanced manufacturing techniques, focusing on ultrasonic machining, sputtering, and focused ion beam milling (FIB). Ultrasonic machining enables precision drilling of hard and brittle materials using ultrasonic vibrations, while sputtering involves bombarding solid targets with ions, creating a plasma for material modification. FIB is a technique employing focused ion beams for micro-machining and analysis, offering high precision at the nanoscale.