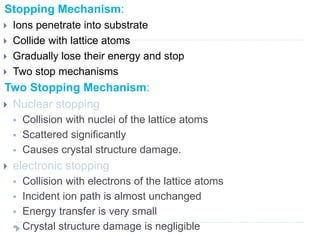

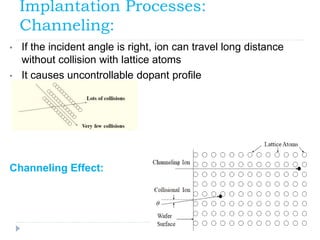

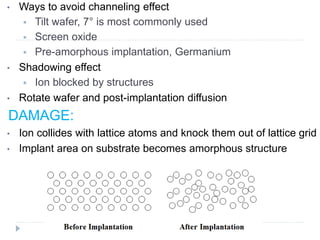

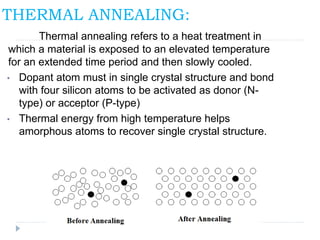

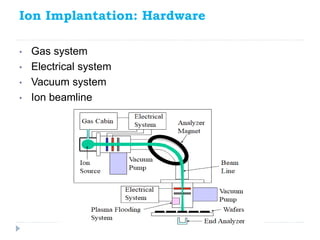

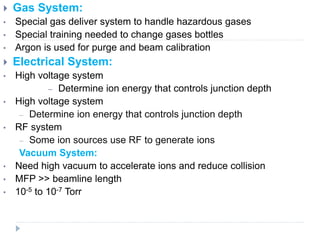

Ion implantation is a process used in semiconductor manufacturing to introduce dopants into a substrate. Ions of the desired element are accelerated into the substrate, changing its properties. The dopant concentration, junction depth, and profile can be controlled by parameters like beam current, implantation time, and ion energy. Implantation causes damage to the crystal structure that must be repaired by annealing at high temperatures. Precise control and cleanroom conditions make ion implantation useful but it also requires complex, hazardous equipment.