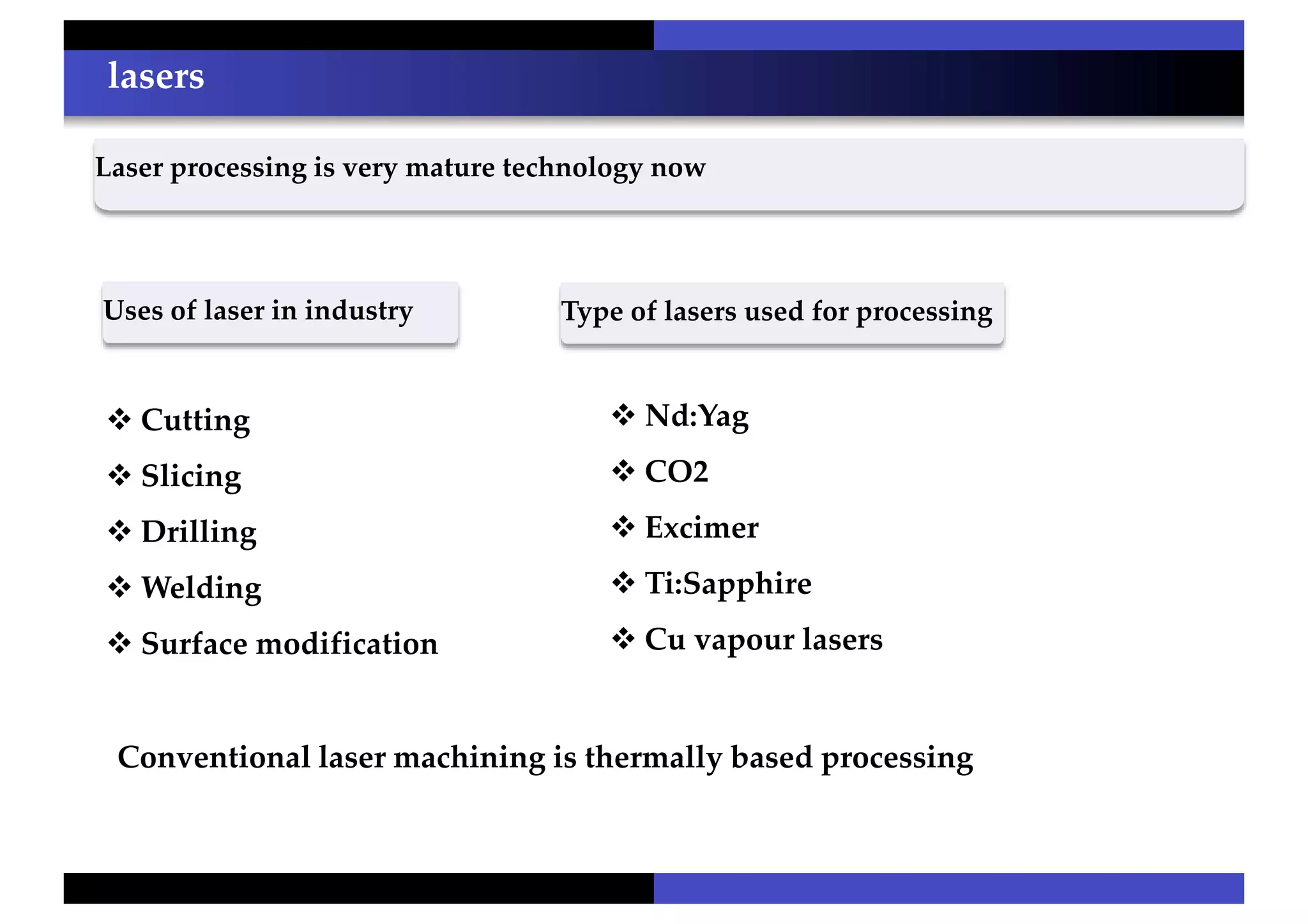

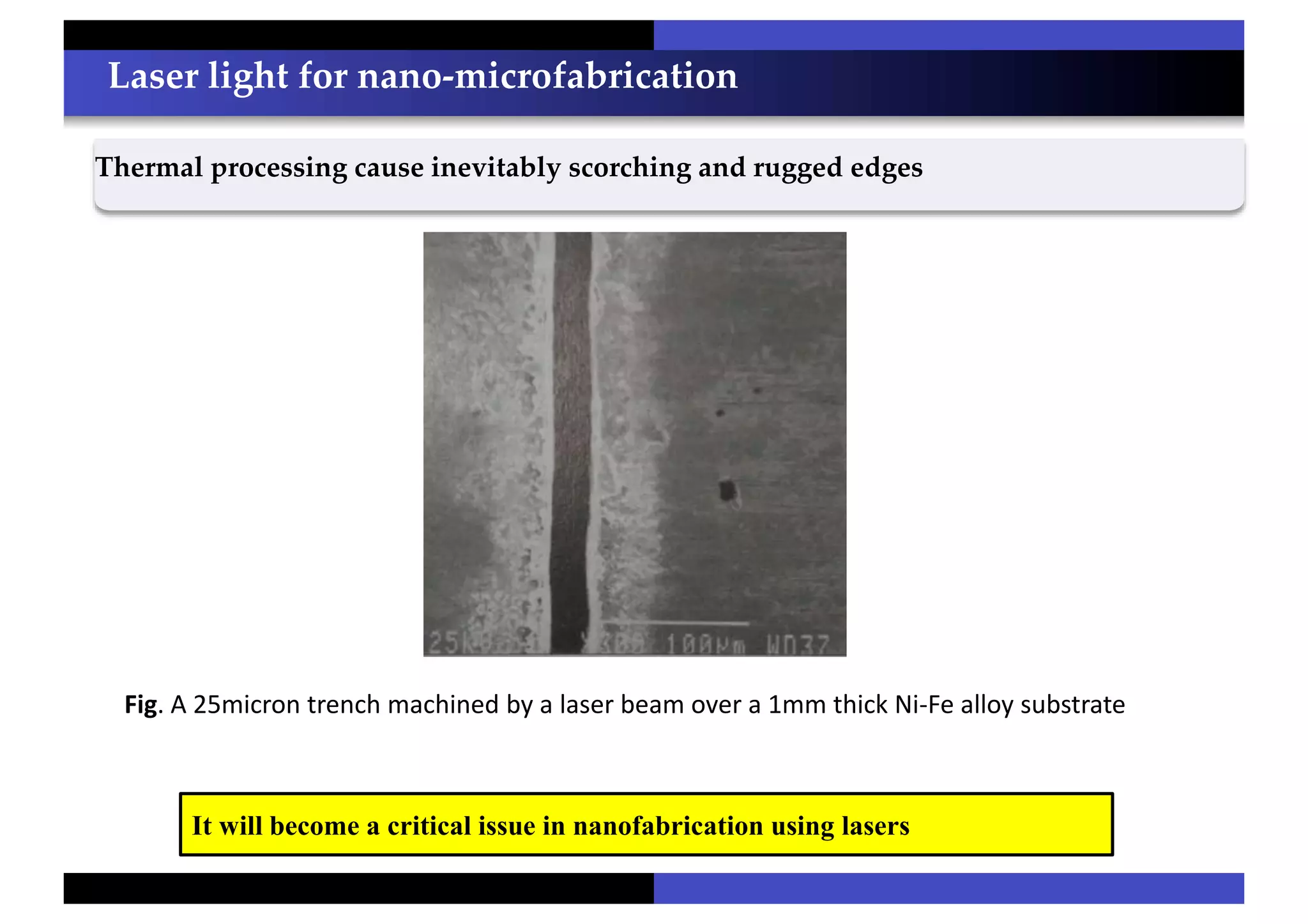

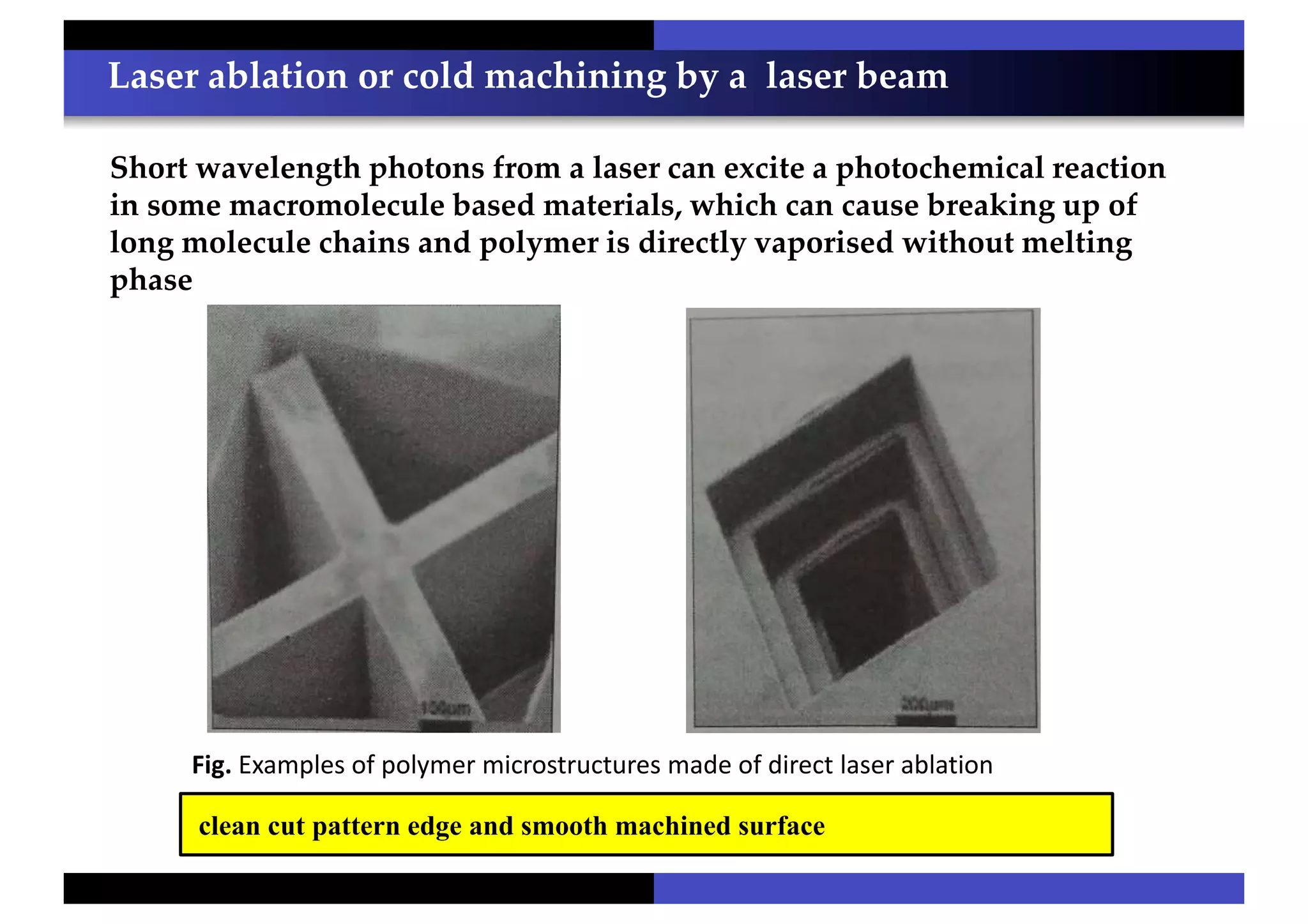

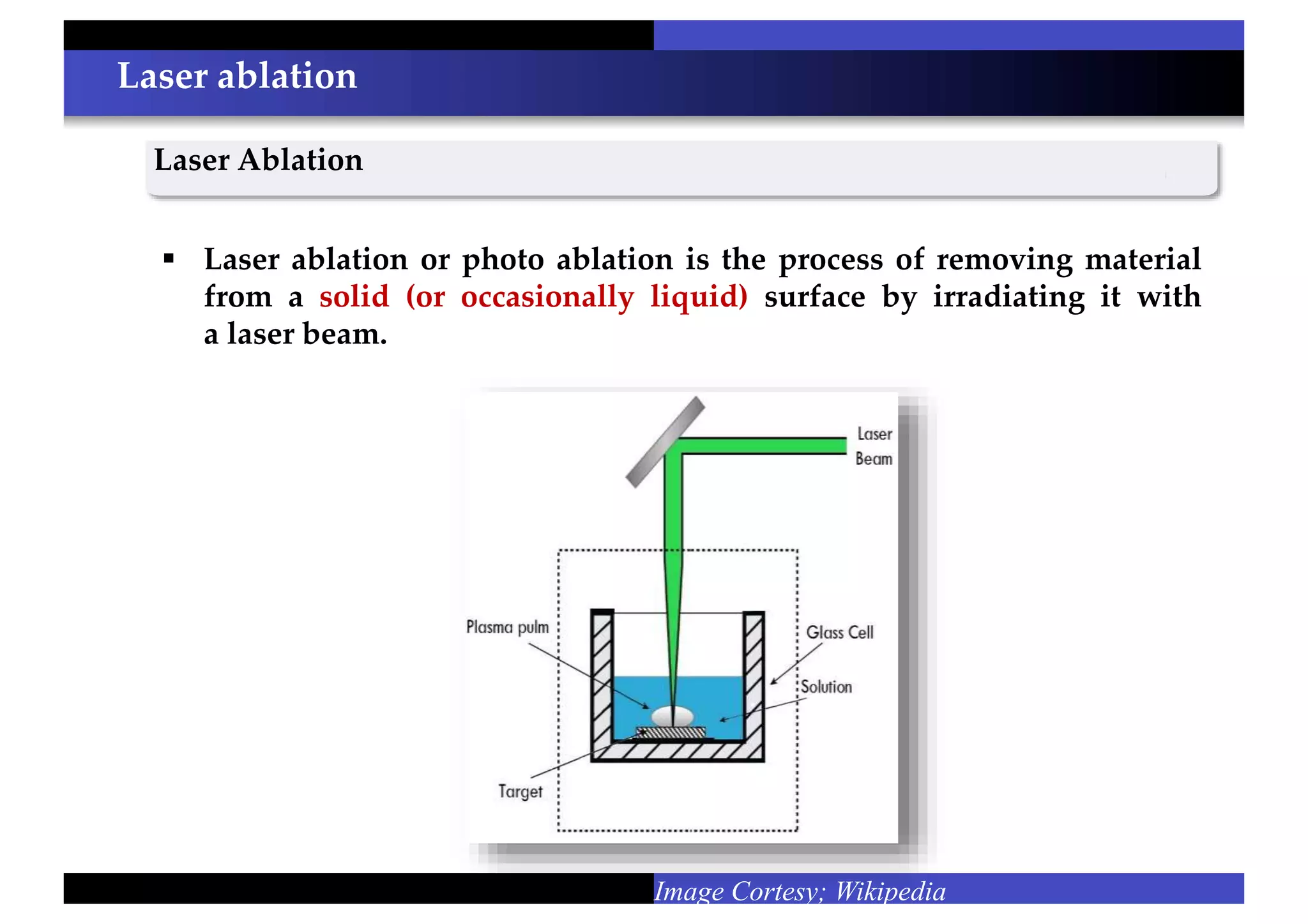

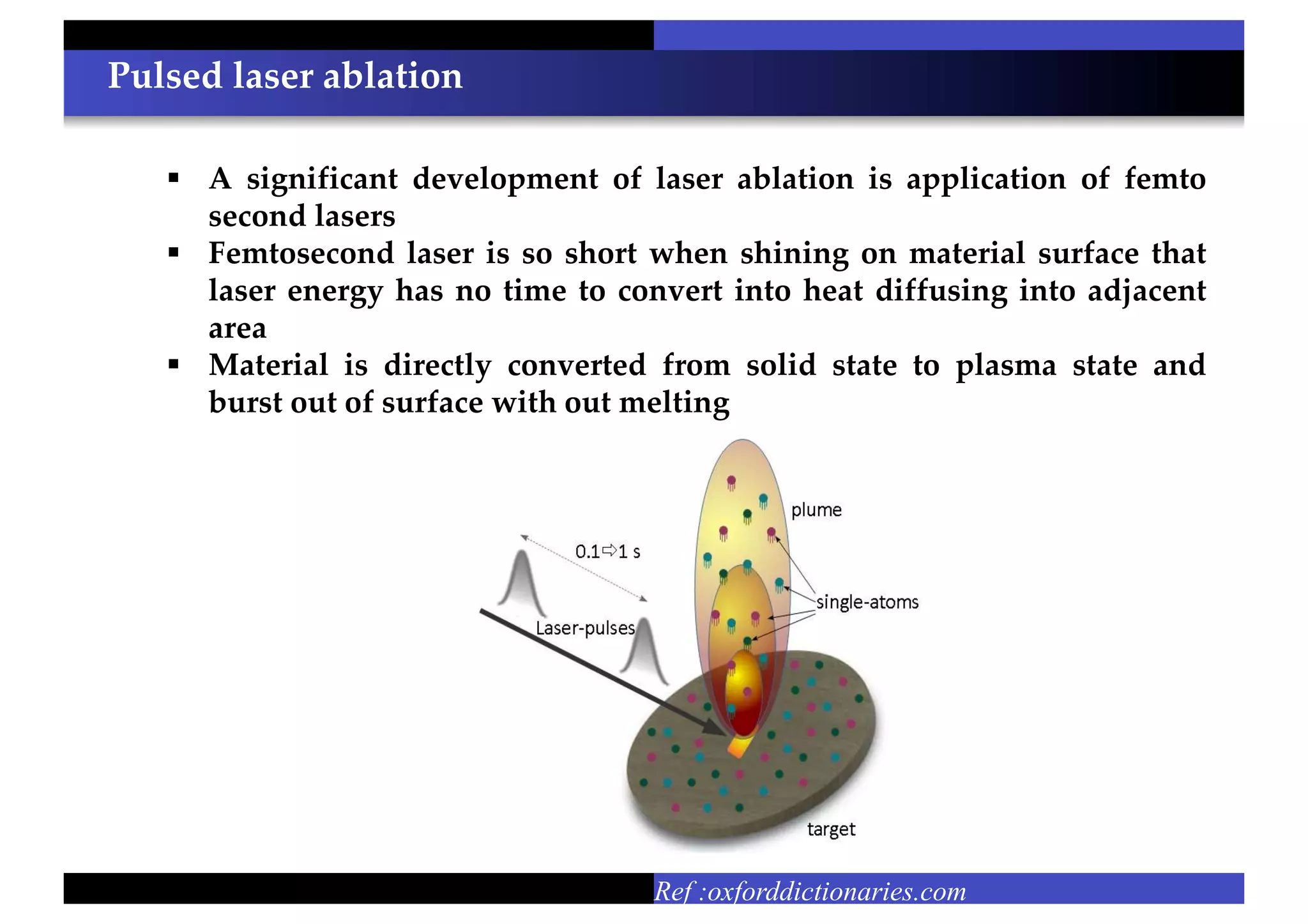

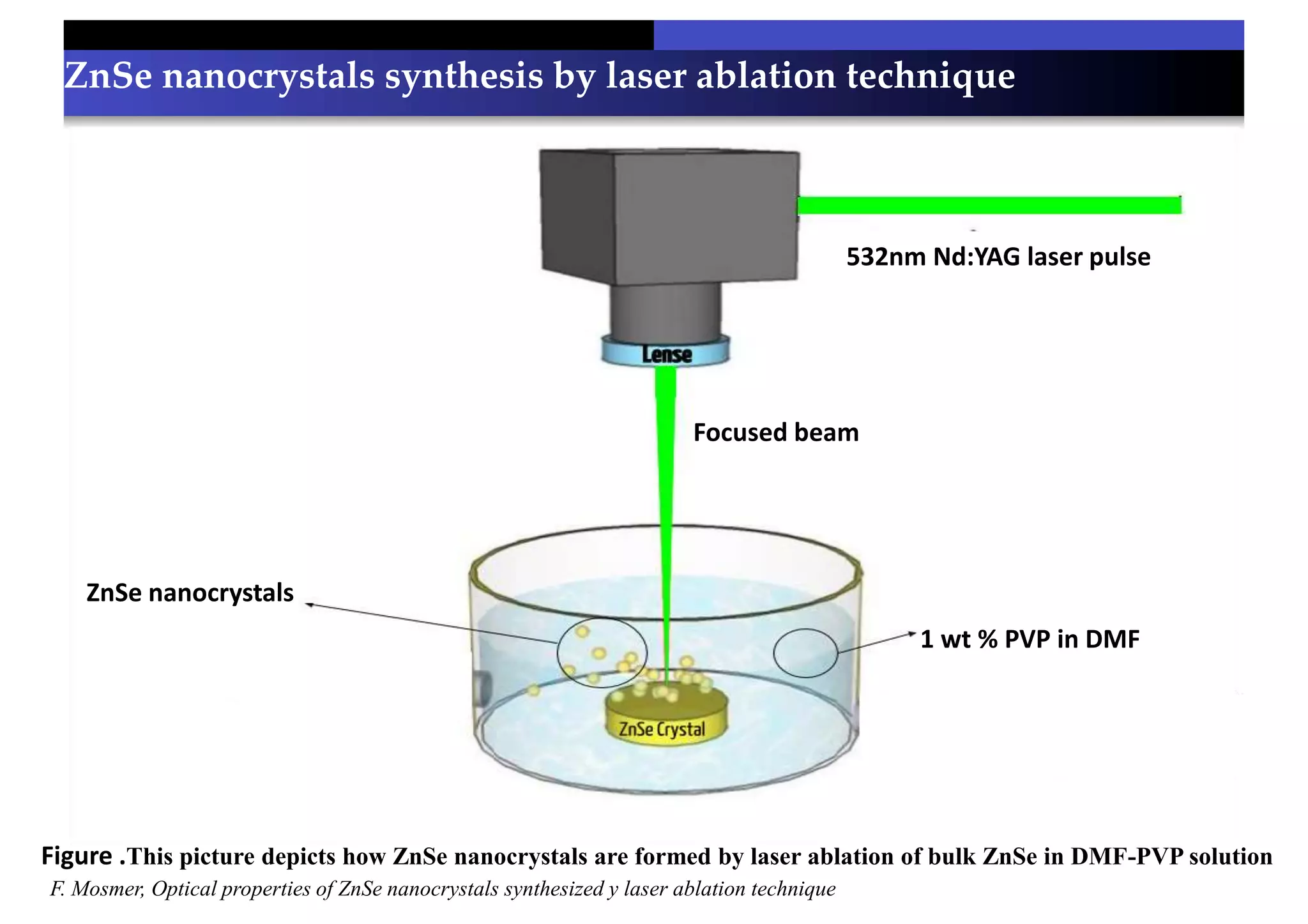

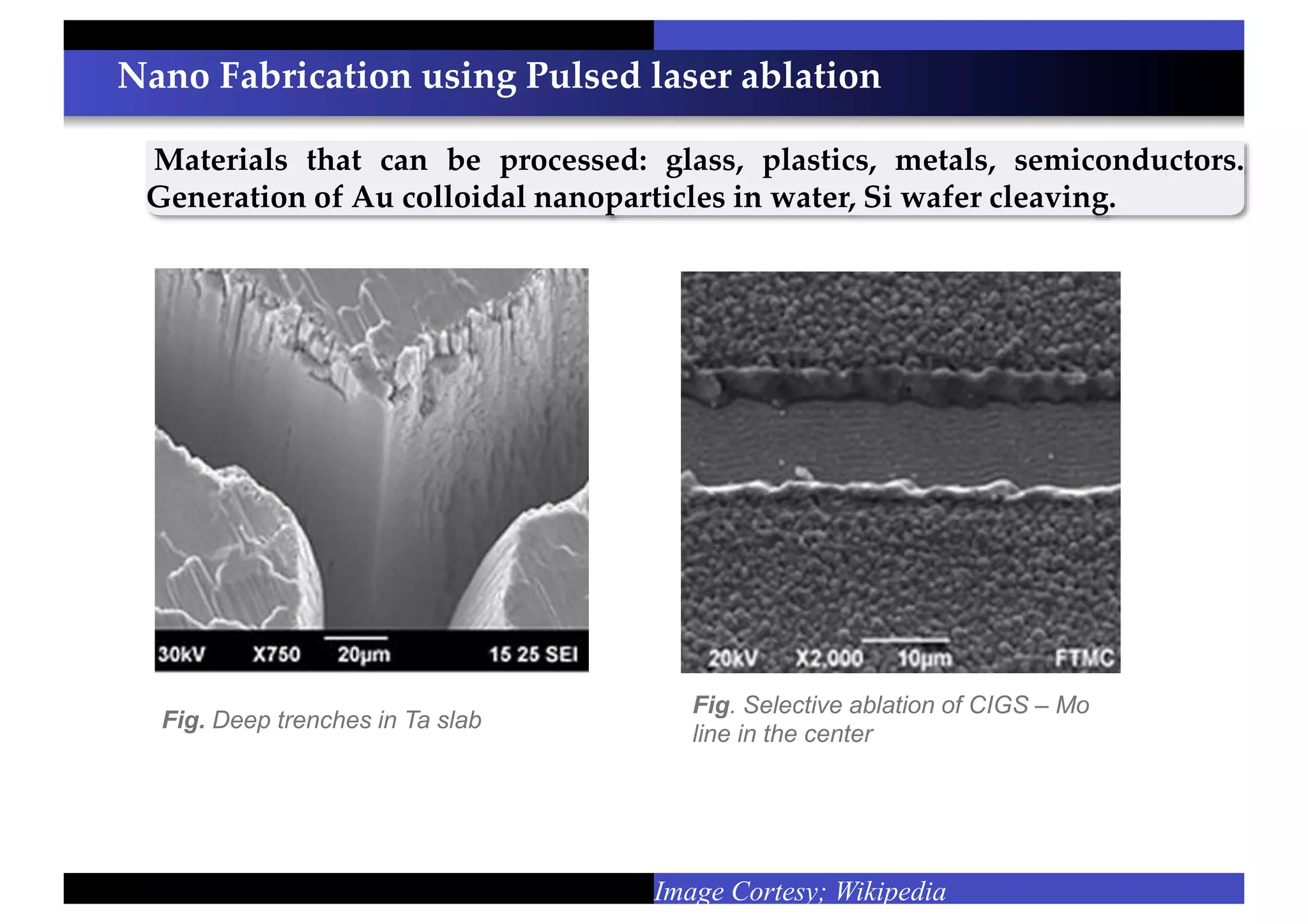

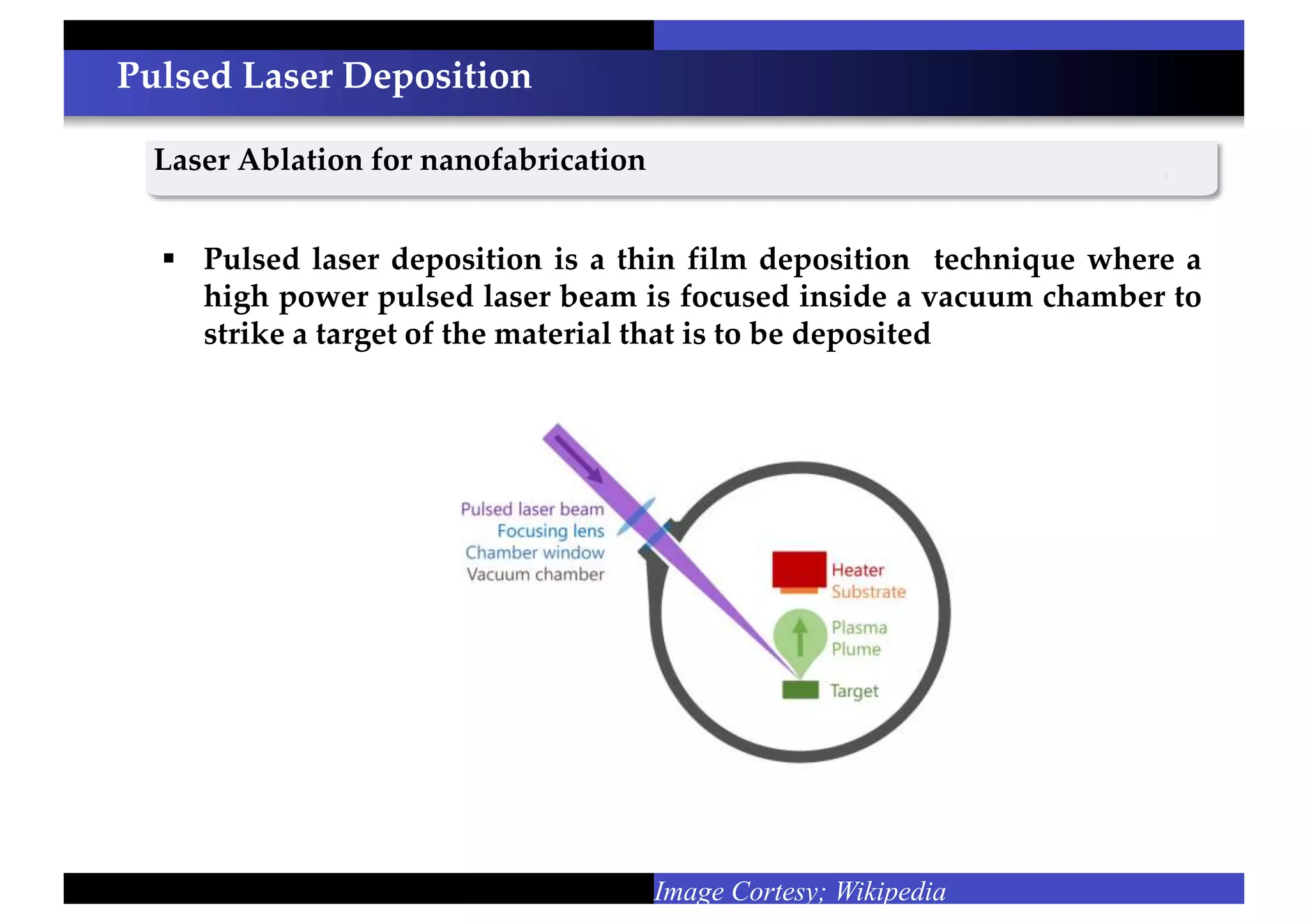

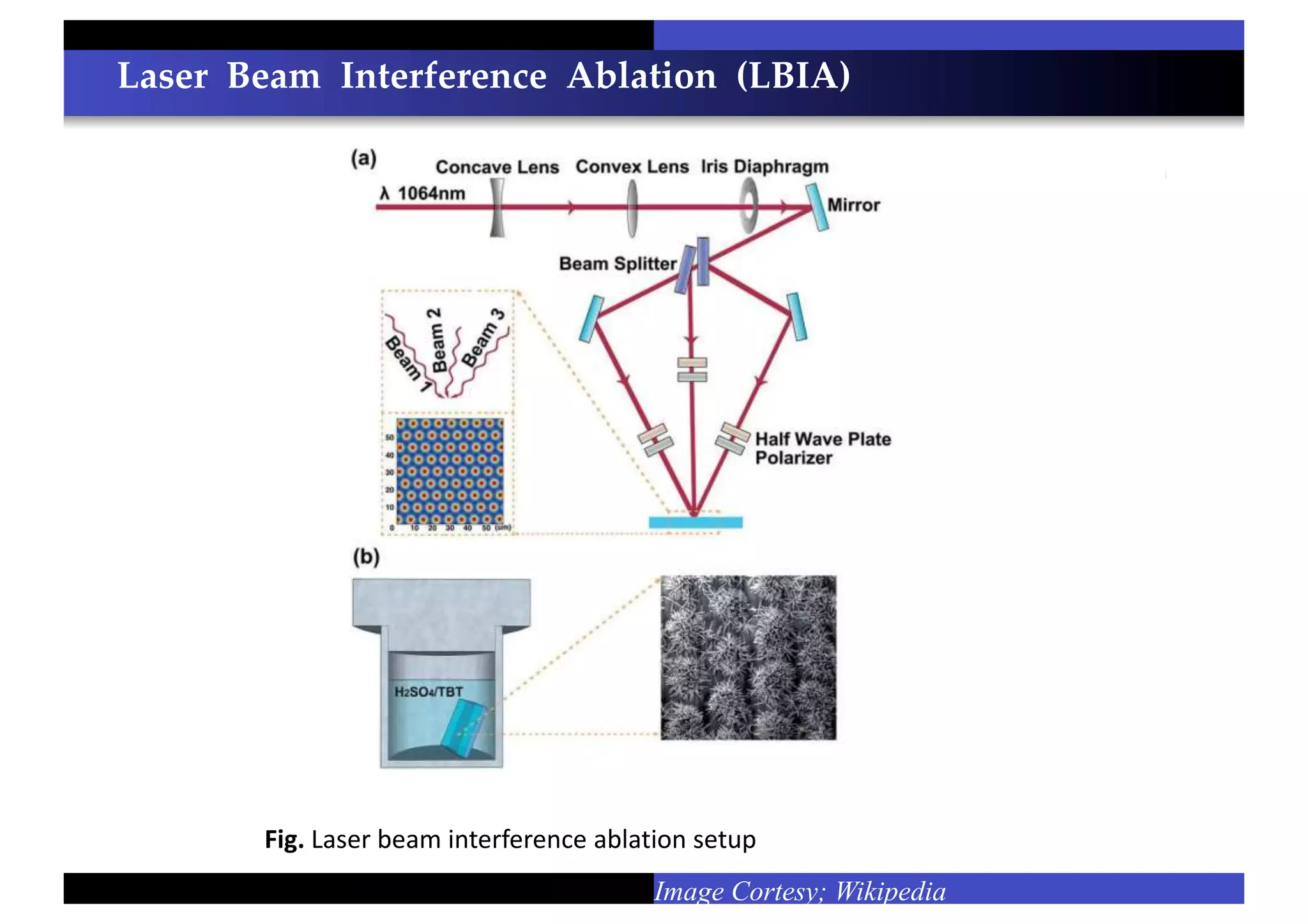

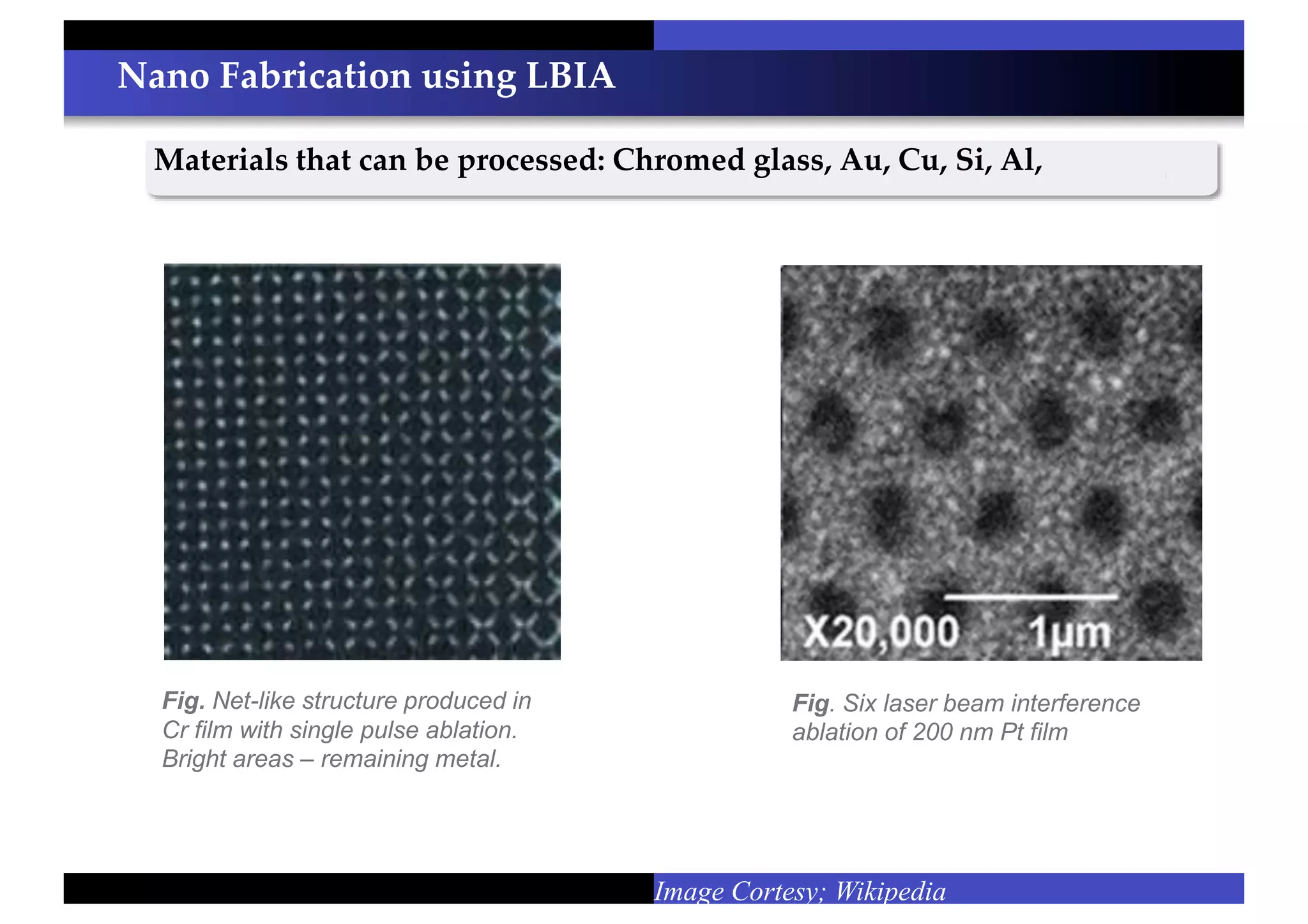

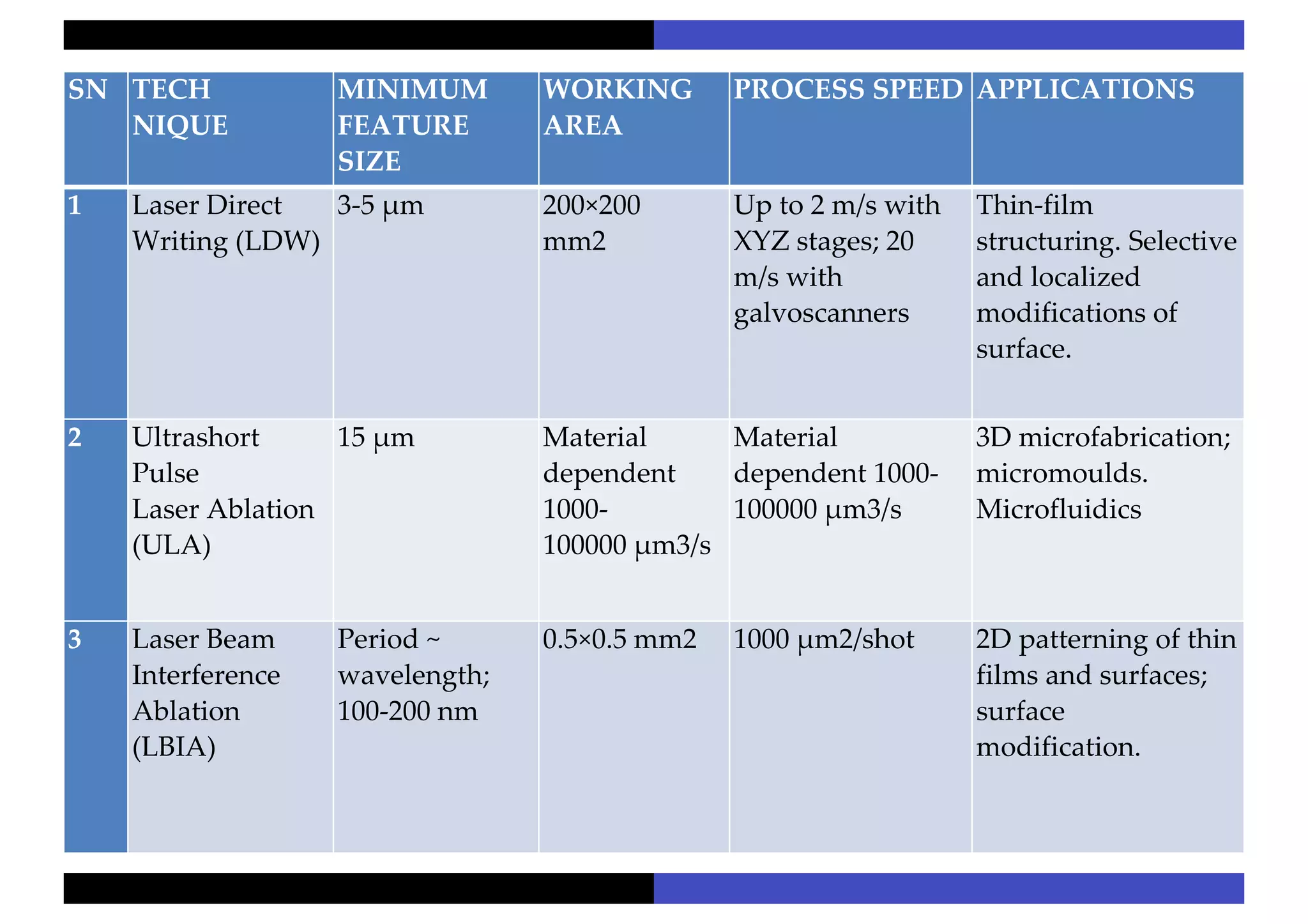

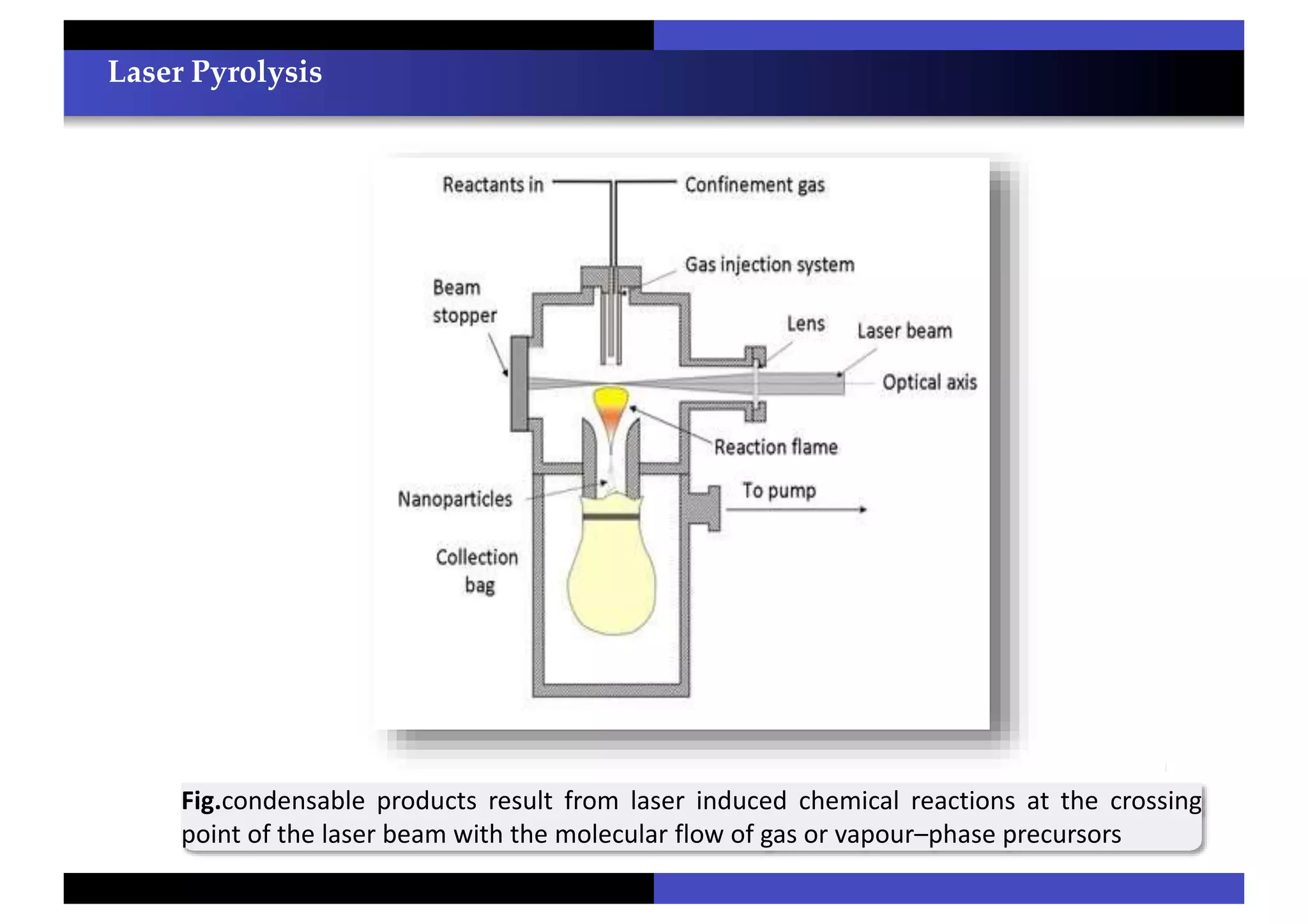

This document discusses laser ablation and pyrolysis techniques. It begins by introducing lasers and their various types and uses. It then describes laser ablation, which is the process of removing material from a surface using a laser beam. Pulsed laser ablation is discussed as a method to machine materials with high precision without causing heat damage. Laser pyrolysis is then covered, which uses high heat from a laser to decompose mixtures of reactants and gases to produce nanoparticles. Specific techniques like pulsed laser deposition and laser beam interference ablation are also summarized.