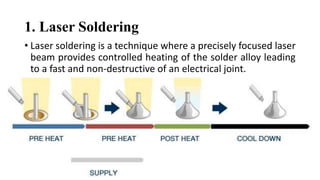

The document discusses laser soldering as a technique that provides controlled heating of solder alloys for efficient electrical joint formation. It outlines various types of laser soldering processes, the lasers used, and comparisons with traditional soldering methods, highlighting advantages such as rapid soldering and minimal thermal stress on components. Additionally, it explores industrial applications across sectors like electronics, automotive, and medical fields.