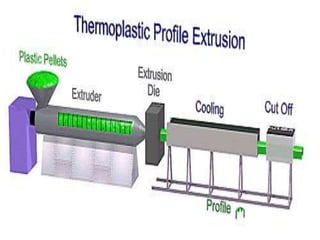

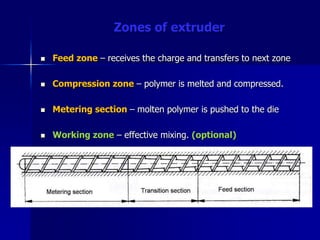

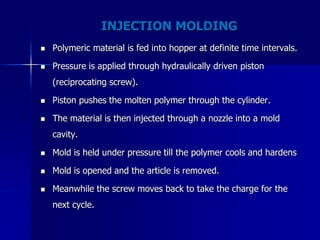

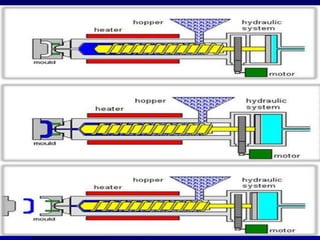

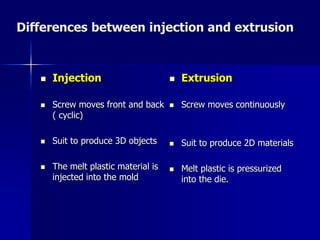

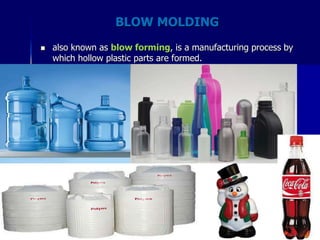

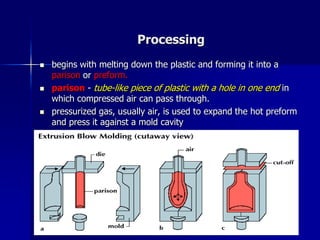

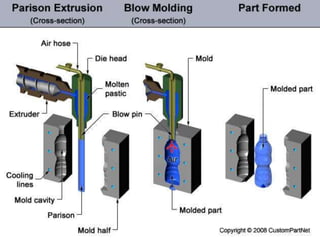

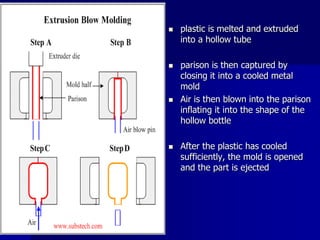

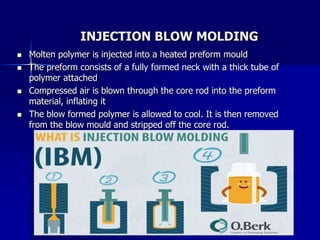

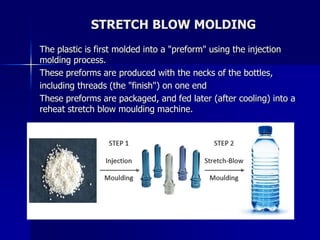

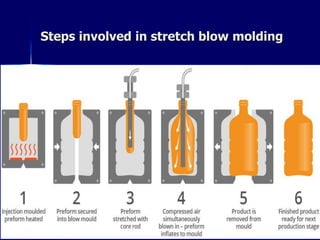

This document discusses various polymer processing and molding techniques. It describes compression molding, extrusion molding, injection molding, and blow molding. Compression molding involves placing polymer material into a mold, applying heat and pressure to form the shape. Extrusion molding uses a screw to force melted polymer through a die to create shapes. Injection molding uses a reciprocating screw to inject melted polymer into a mold cavity. Blow molding forms hollow plastic parts by extruding or injecting a tube then inflating it against a mold with compressed air.