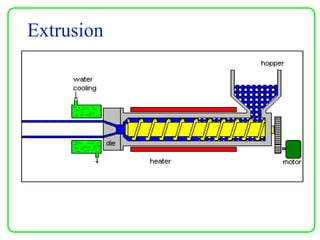

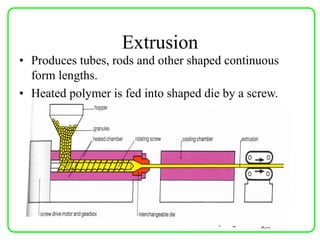

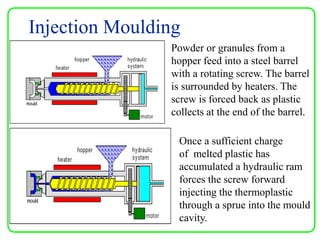

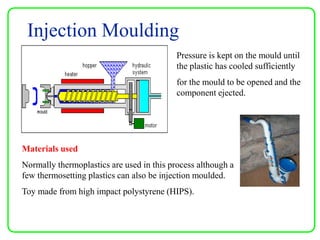

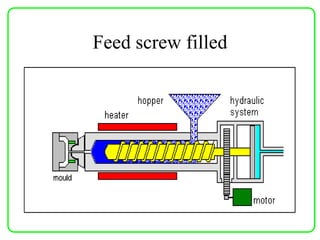

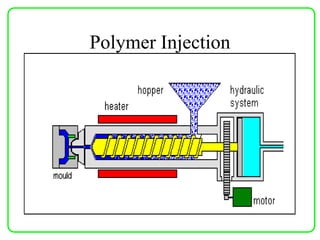

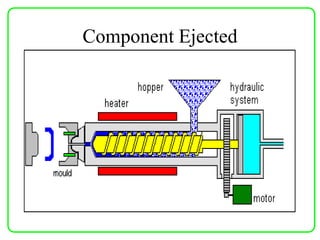

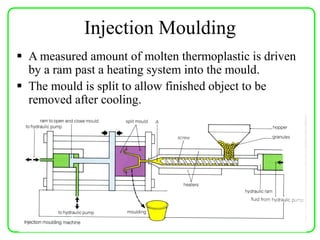

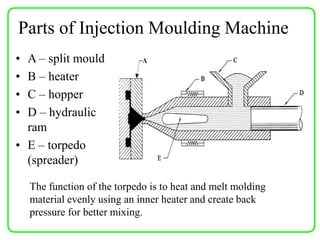

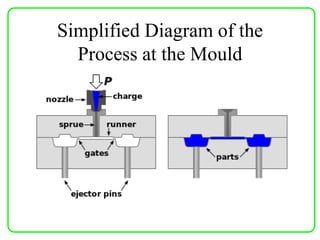

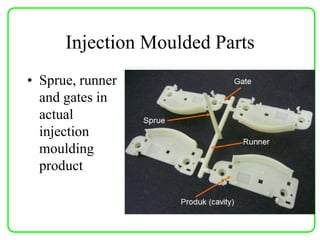

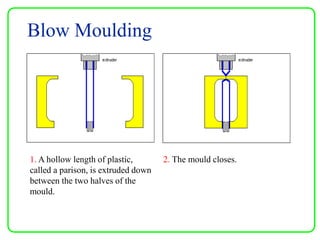

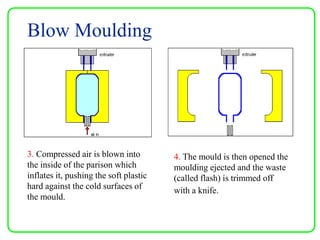

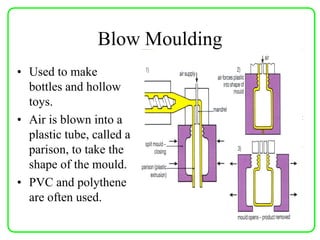

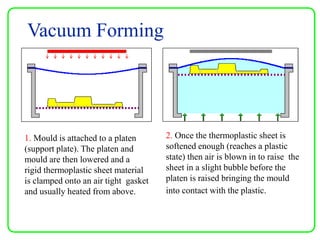

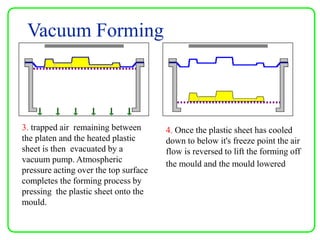

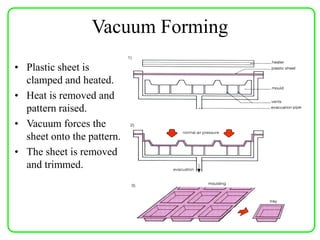

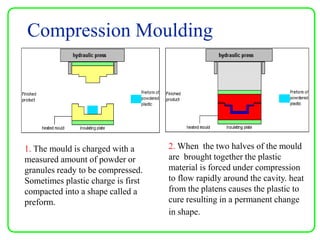

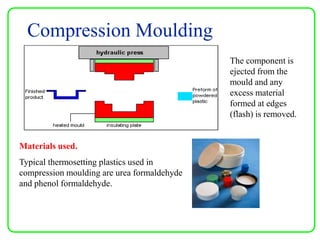

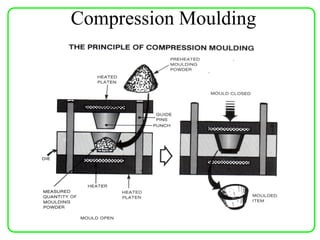

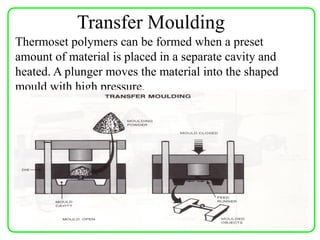

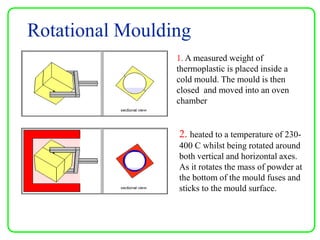

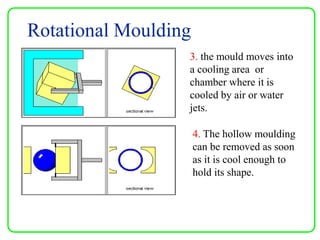

Extrusion is a continuous process that produces solid or hollow products of constant cross-section like pipes or profiles. Molten plastic is fed into a heated barrel by a screw and forced through a die. Injection moulding injects molten plastic into a mould cavity under pressure to form complex shapes. Blow moulding uses compressed air to inflate a hollow tube of plastic against a mould. Vacuum forming uses heat and vacuum pressure to form plastic sheets over moulds. Compression moulding uses heat and pressure to cure thermoset plastics in a mould. Rotational moulding rotates a mould containing plastic powder to coat the inside with a uniform layer that is then