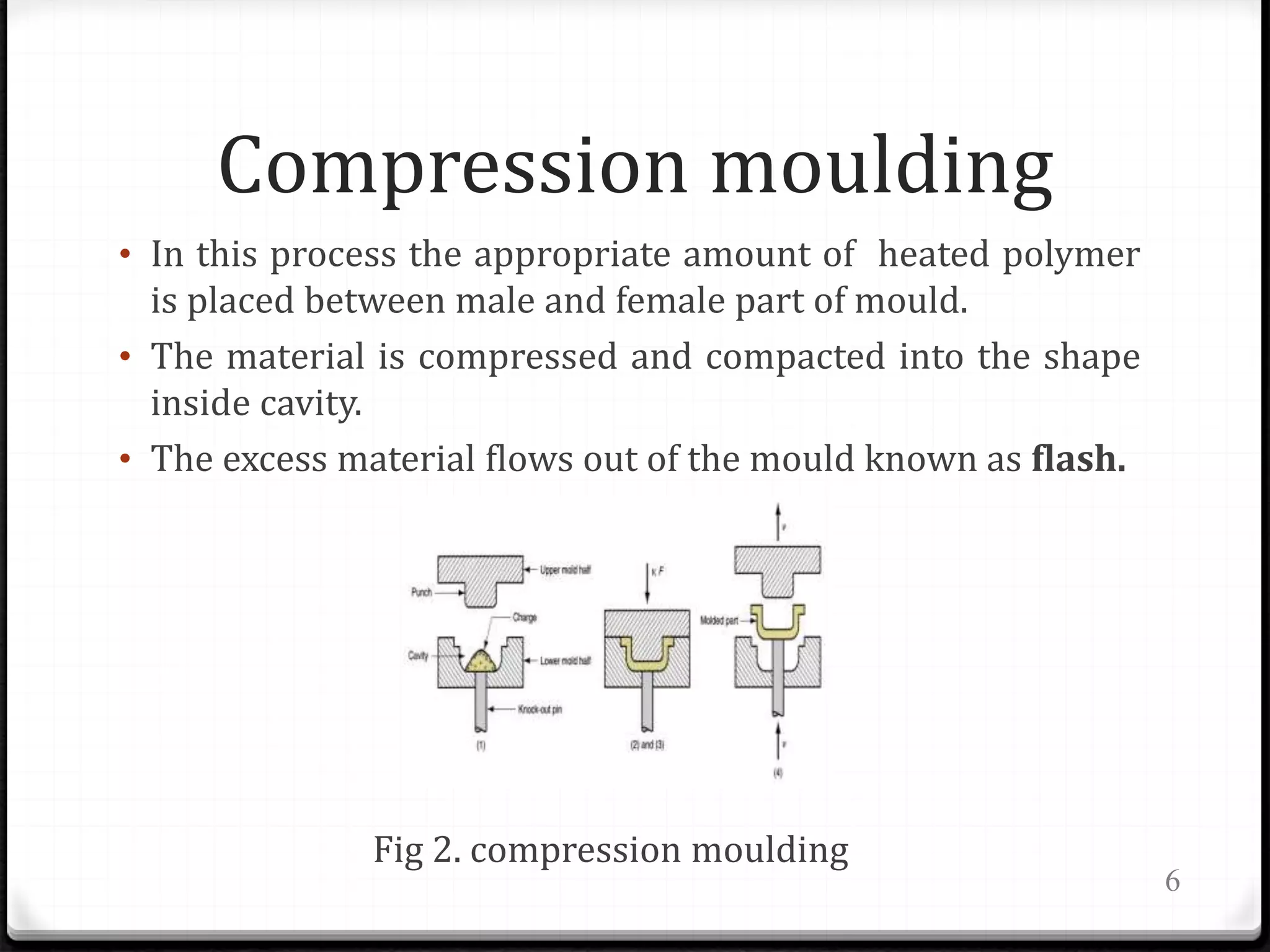

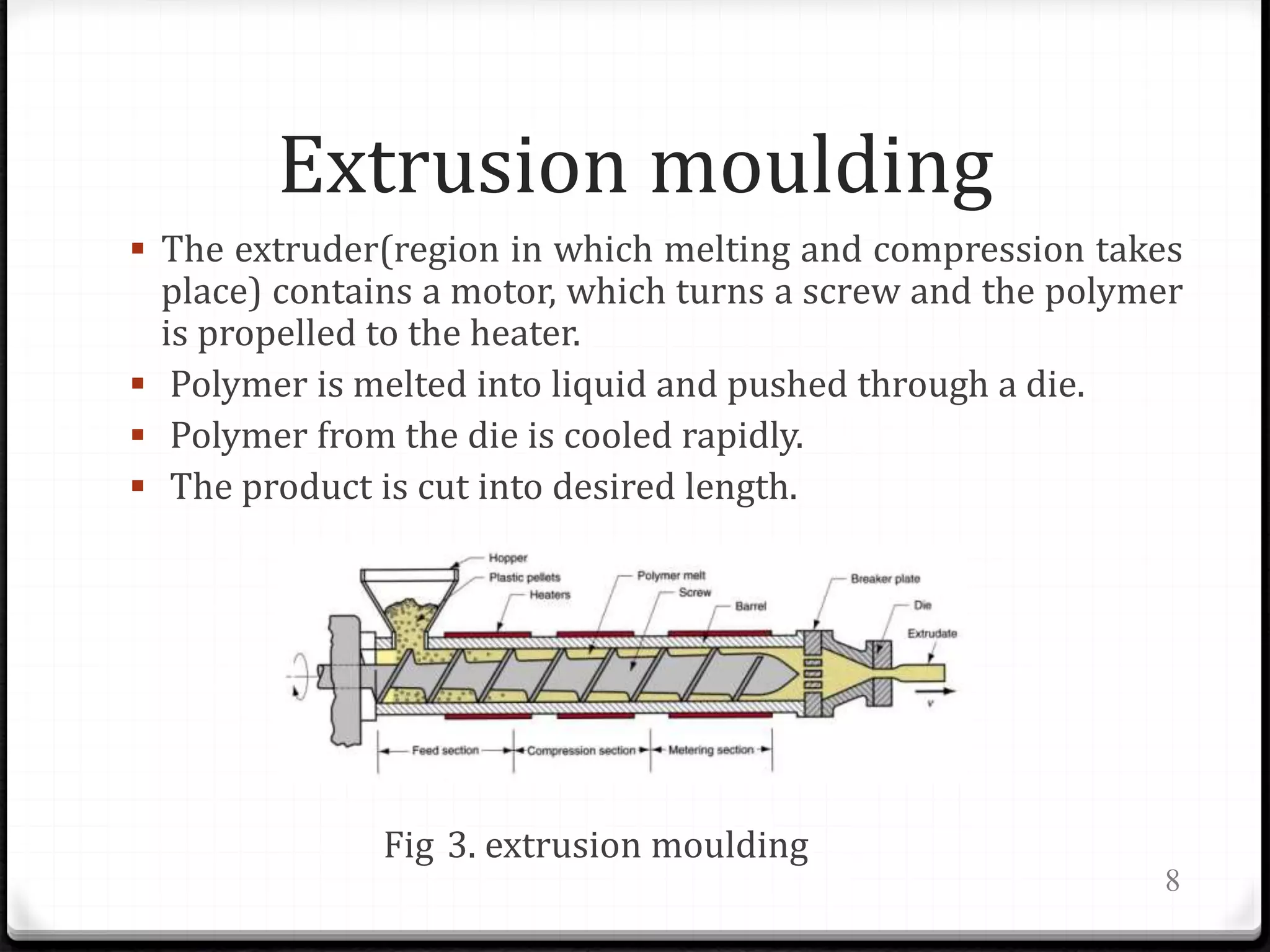

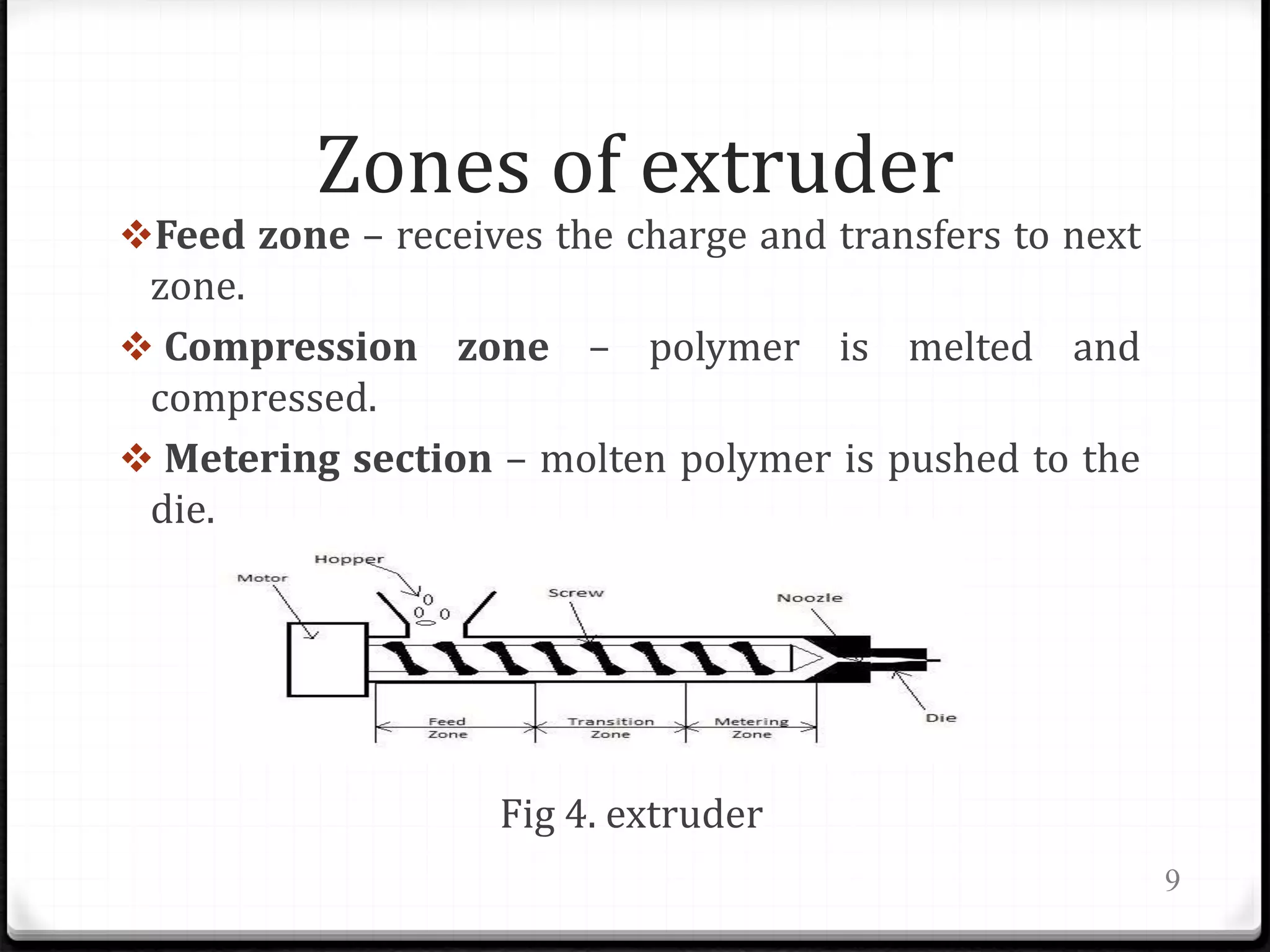

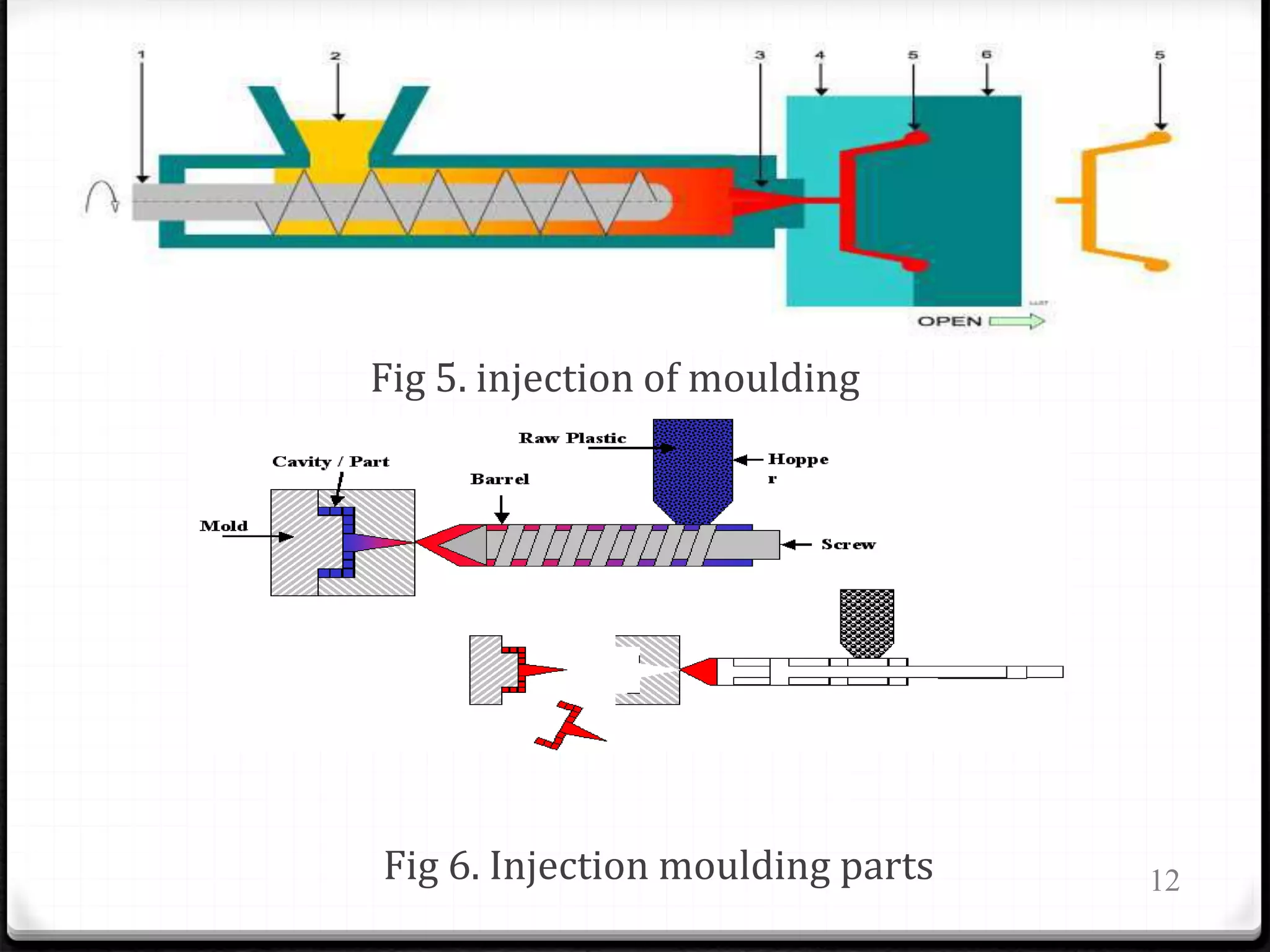

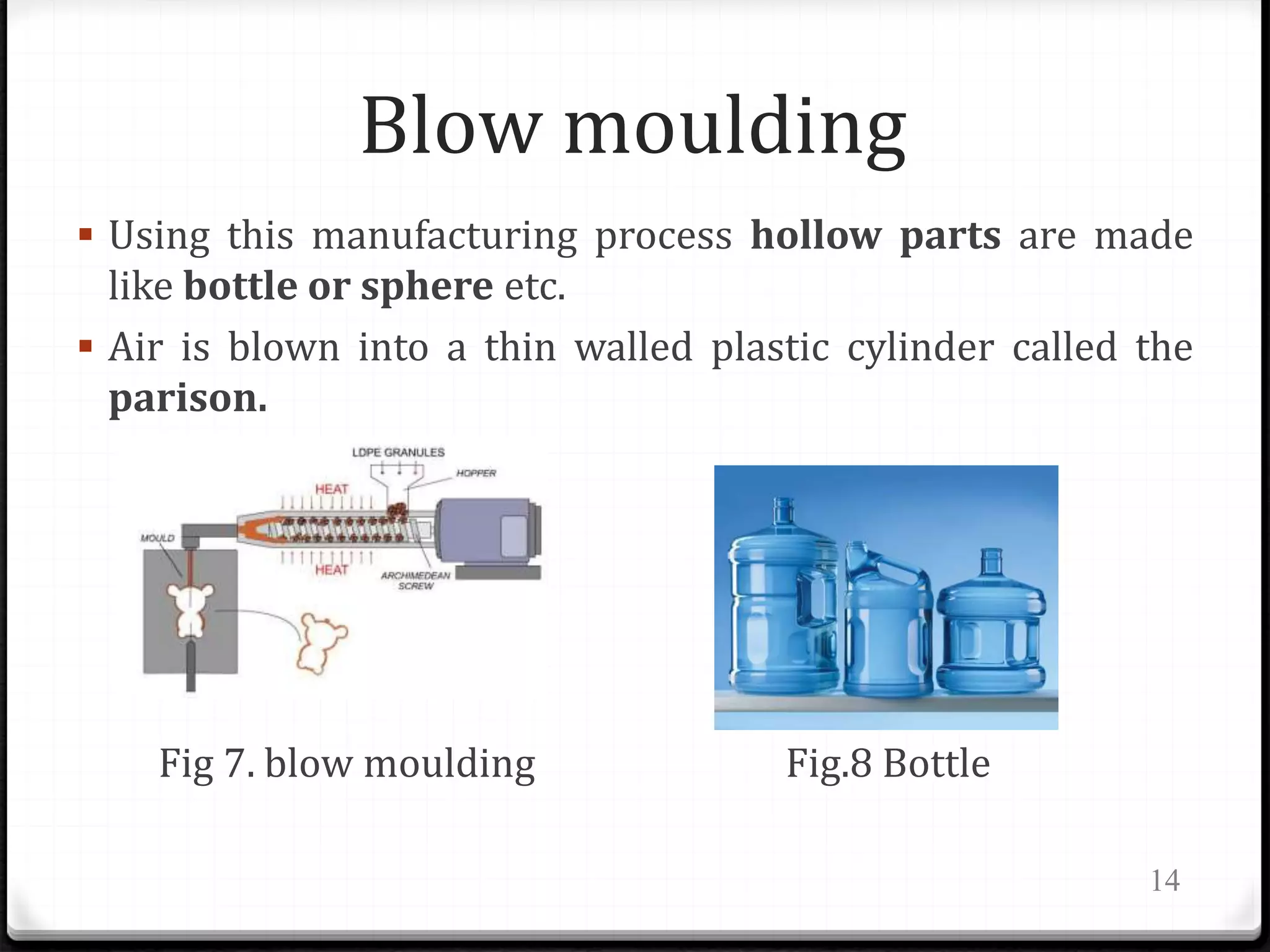

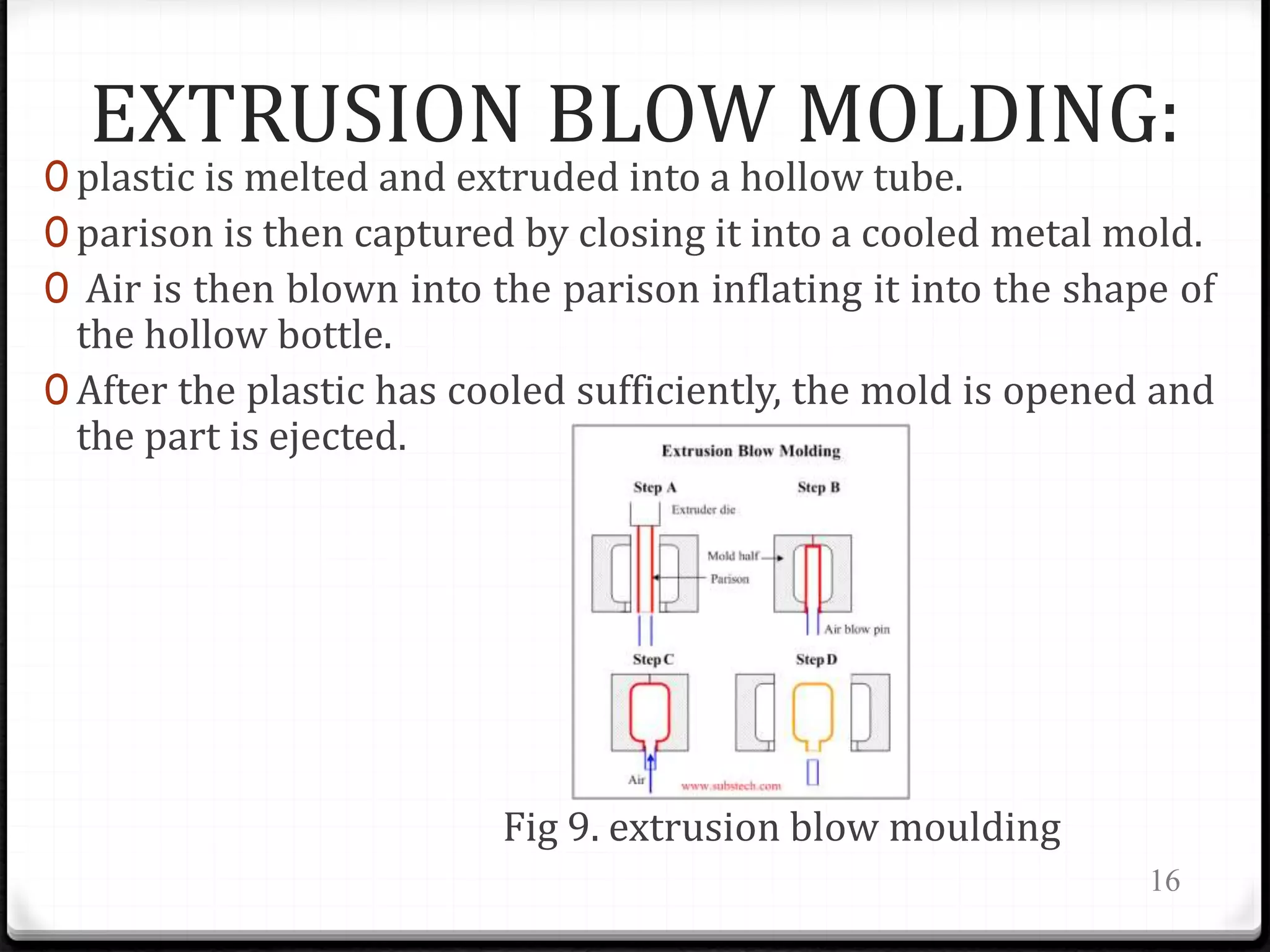

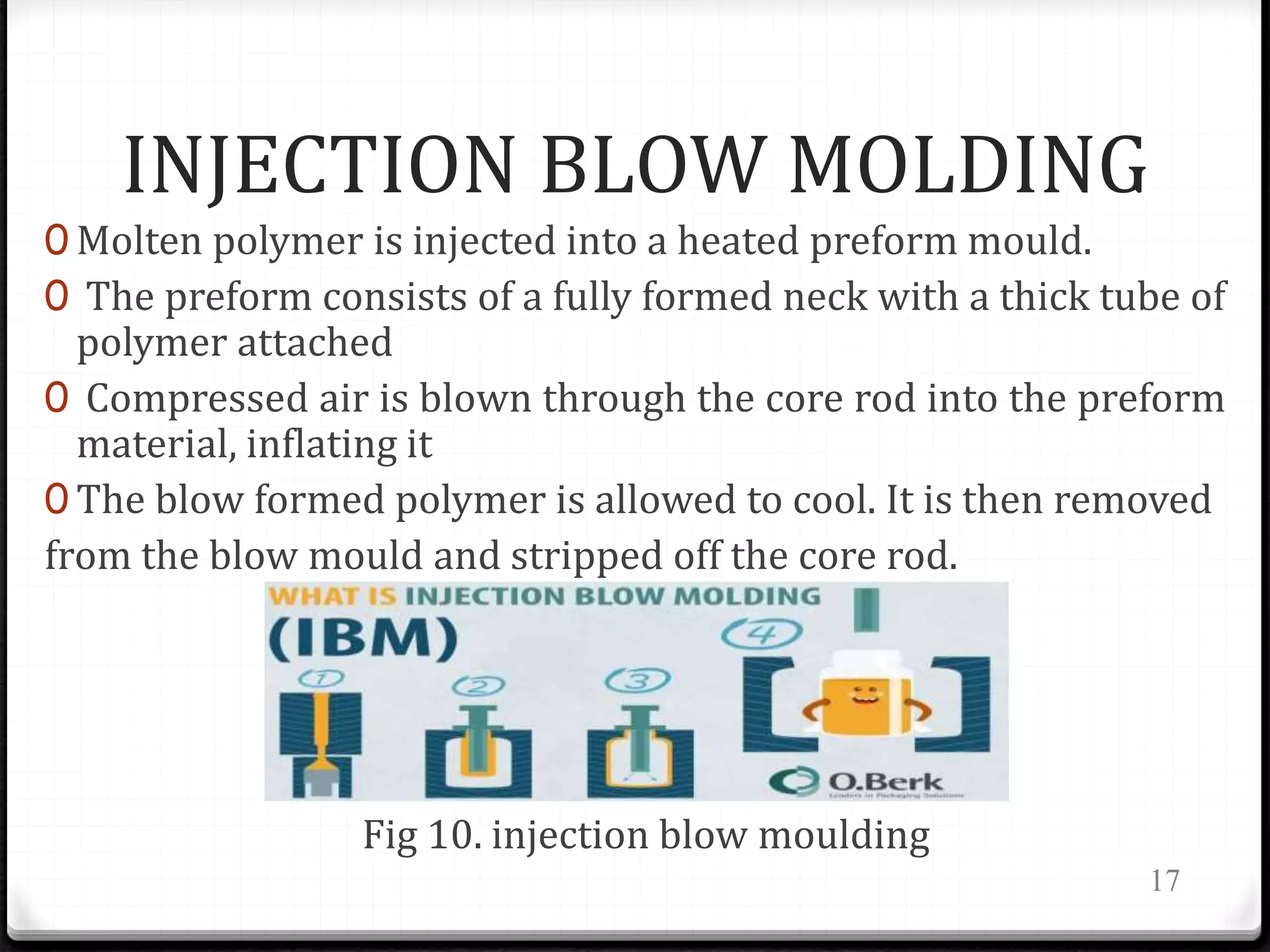

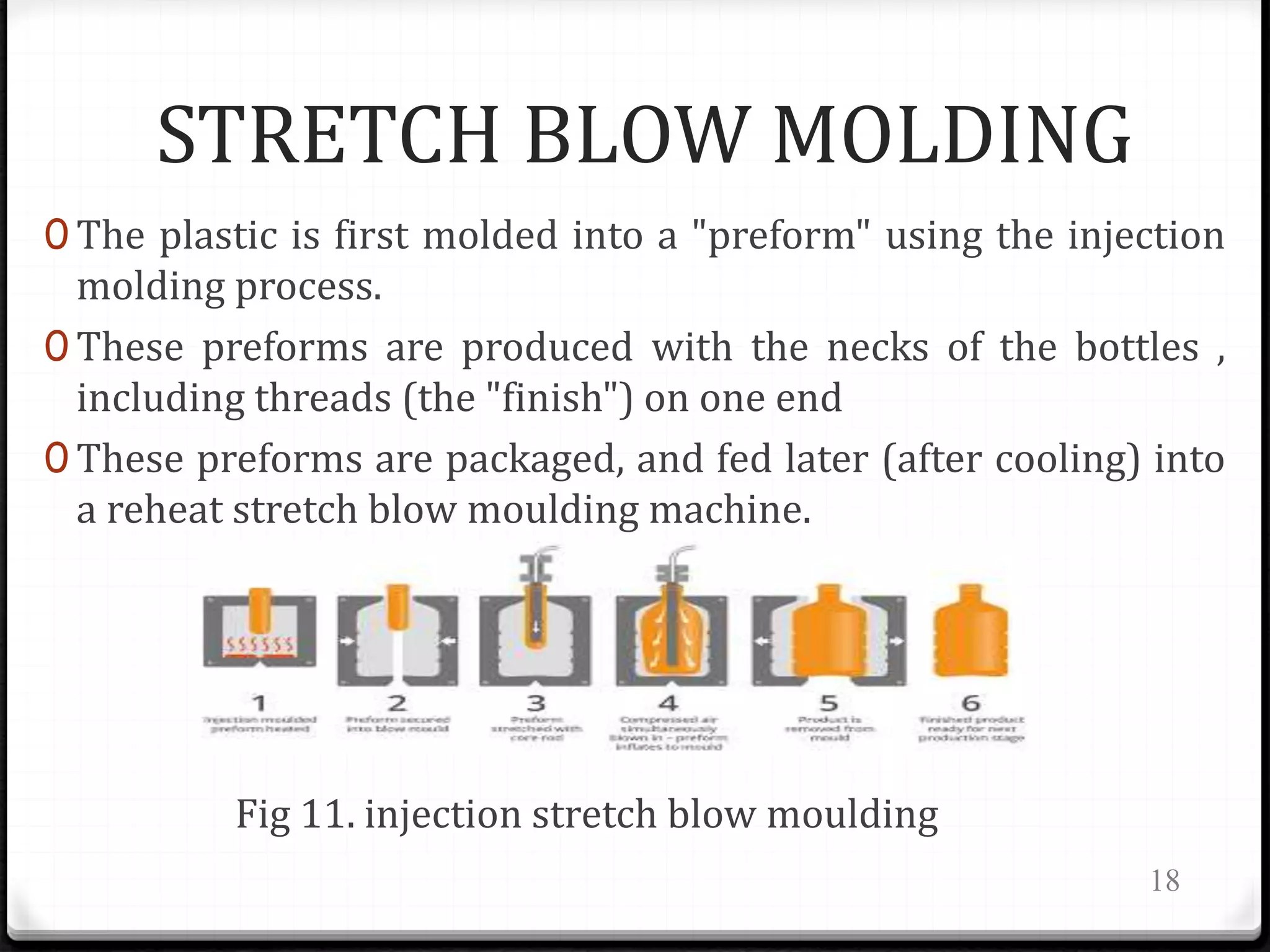

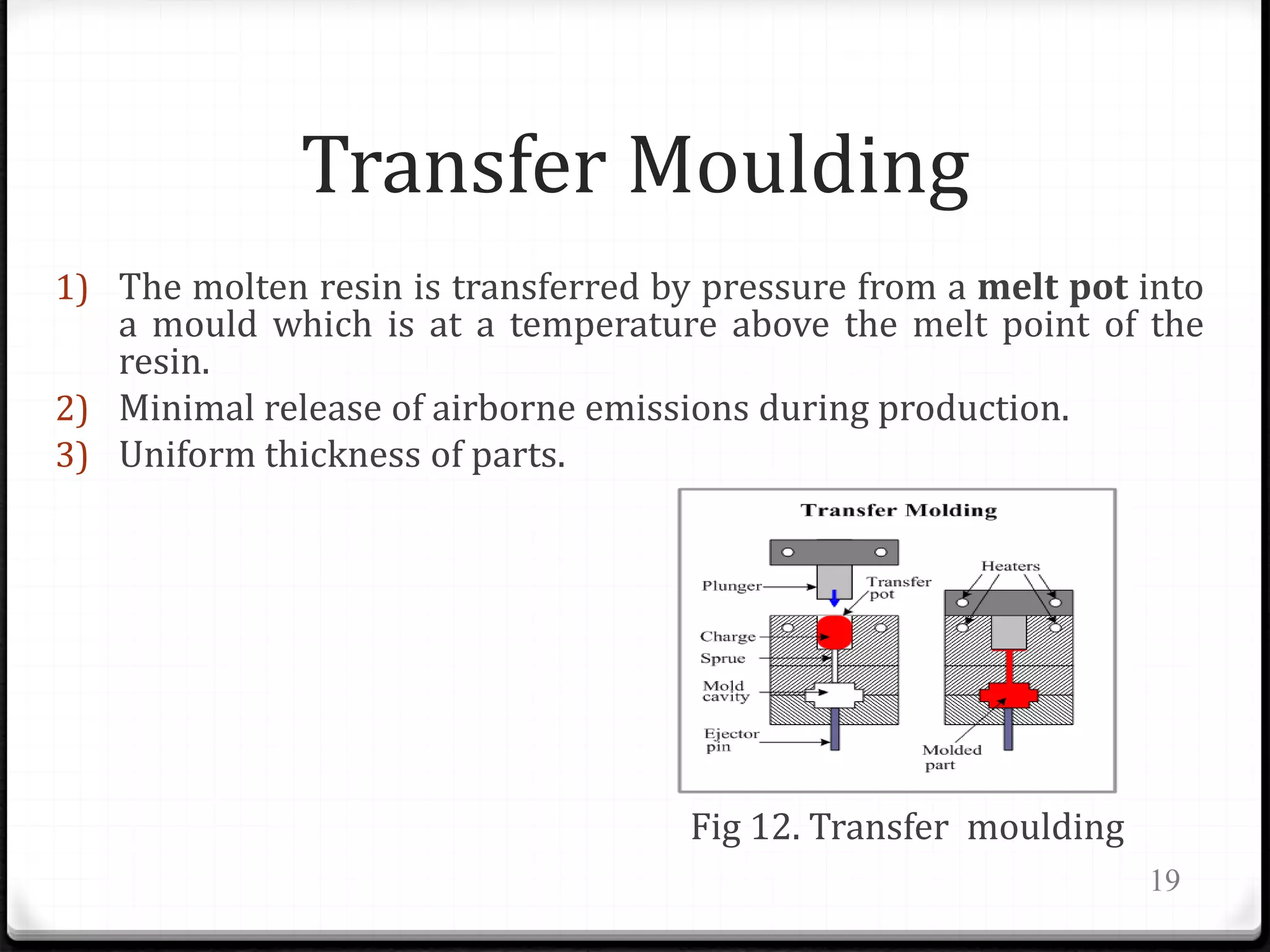

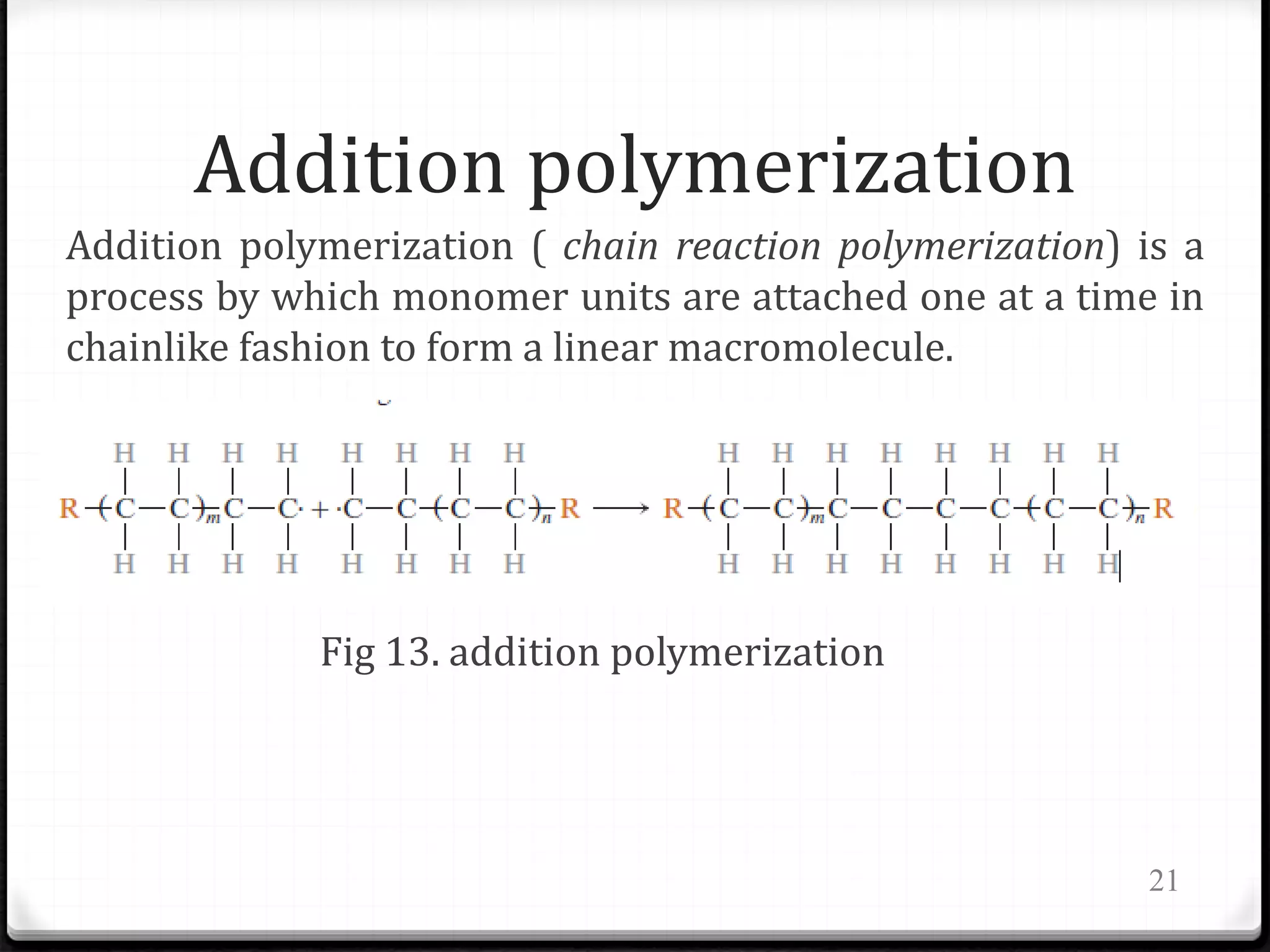

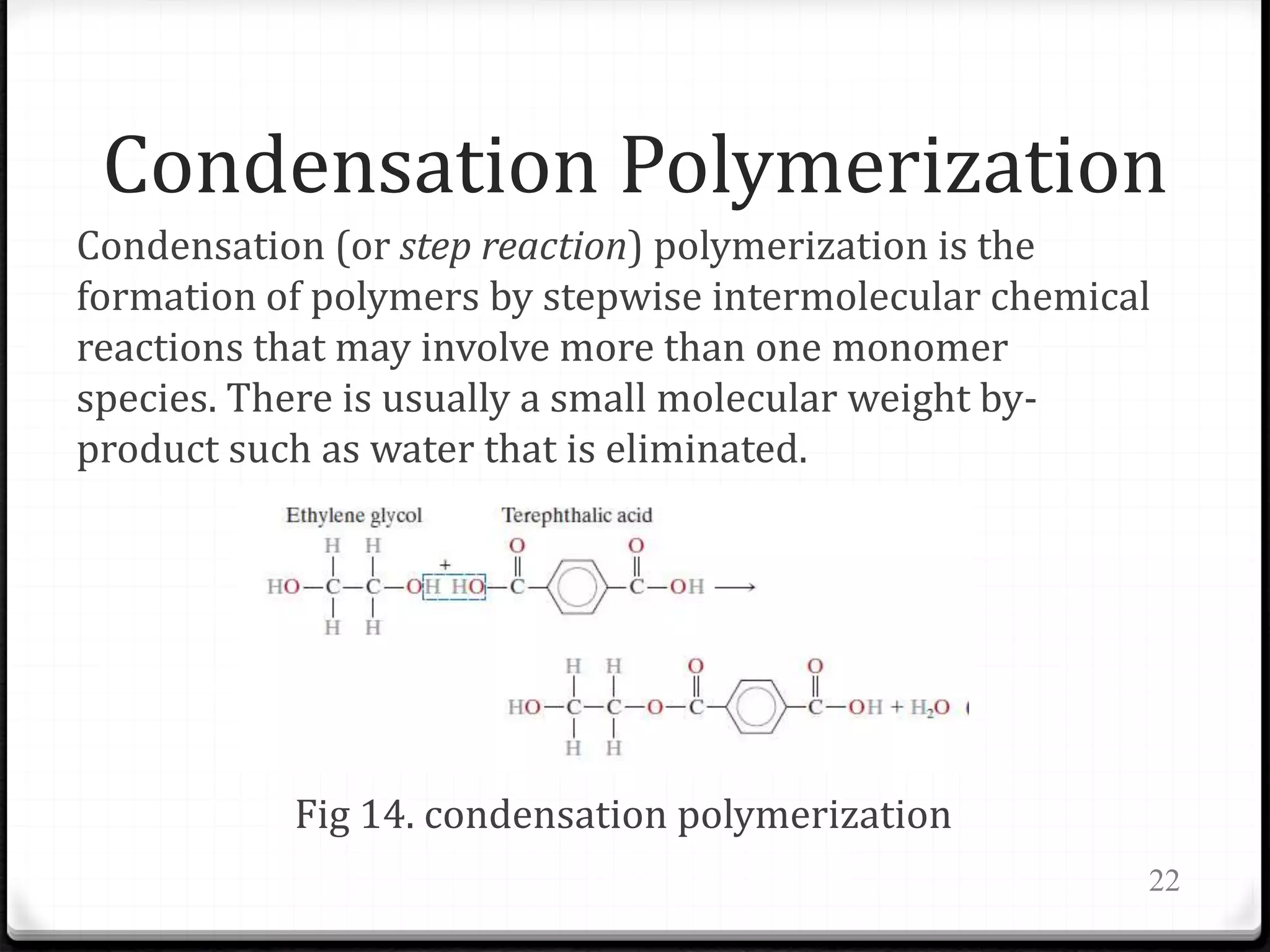

The document outlines the definition and types of polymers, emphasizing their significance in various applications such as plastics, rubbers, and medical materials. It describes different polymer processing methods, including compression, extrusion, injection, blow, and transfer molding, detailing how each method functions and the types of products they produce. Additionally, it explores the polymerization processes of addition and condensation, along with several applications in medicine, consumer products, industry, and sports.