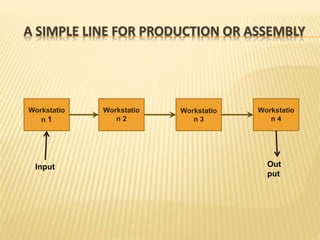

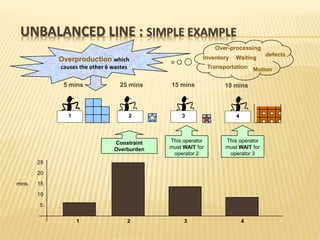

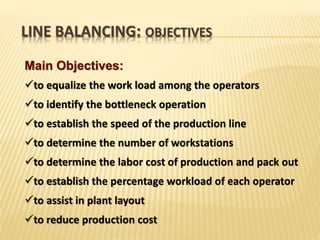

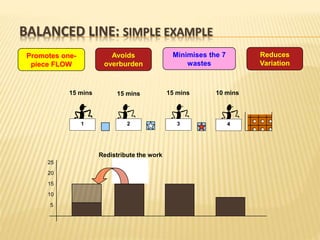

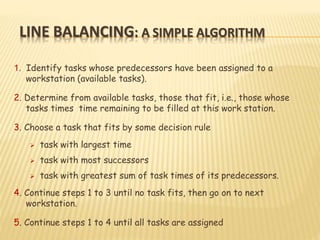

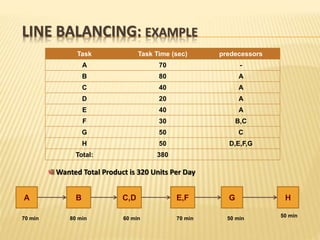

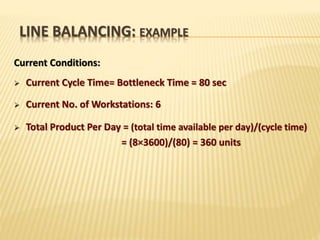

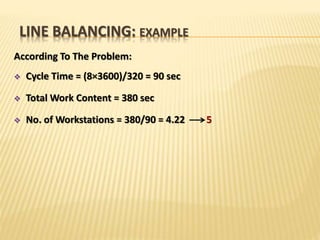

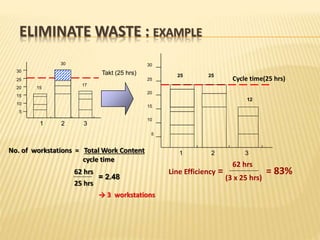

This document provides an overview of line balancing. It defines line balancing as assigning tasks to workstations to equalize workloads and cycle times. The objectives of line balancing include equalizing workloads, identifying bottlenecks, establishing production speeds, determining staffing needs, and reducing costs. Common methods are described along with concepts such as precedence diagrams, work content, and cycle times. A simple example is provided to demonstrate how to balance a line to increase efficiency from 79% to 84% by redistributing tasks among five workstations. The document emphasizes eliminating waste to further improve efficiency.