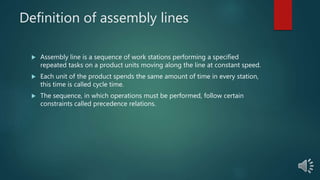

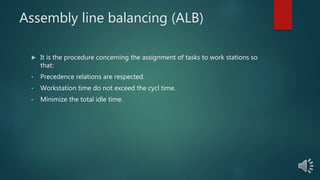

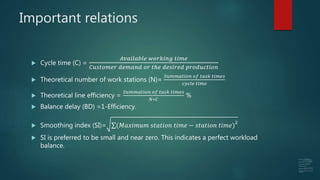

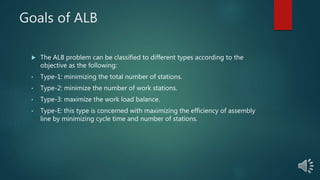

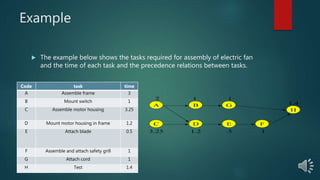

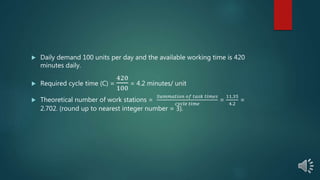

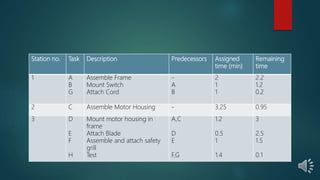

The document explains assembly line balancing (ALB), which is the process of assigning tasks to workstations while respecting precedence relations, ensuring cycle time is not exceeded, and minimizing idle time. It discusses concepts like cycle time, theoretical number of workstations, balance delay, and various types of ALB problems focused on efficiency and workload balance. An example illustrates these principles with a case for assembling electric fans, detailing tasks, times, and daily production requirements.