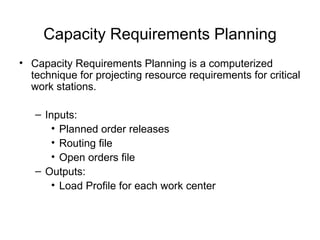

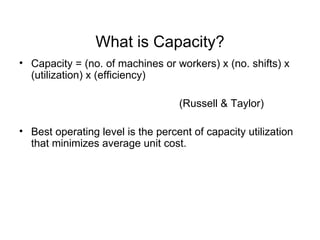

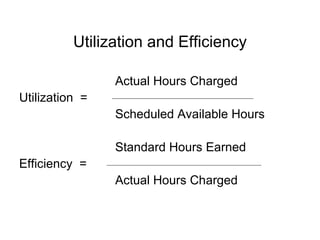

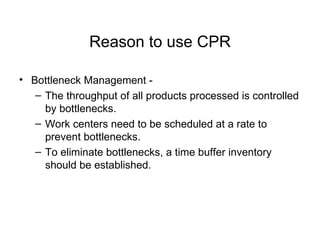

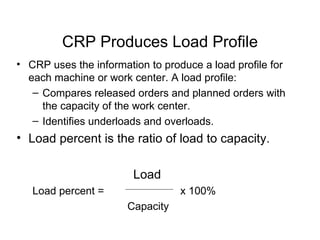

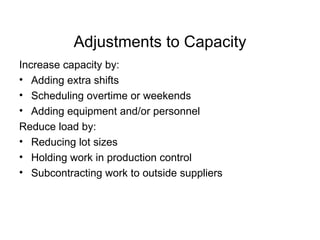

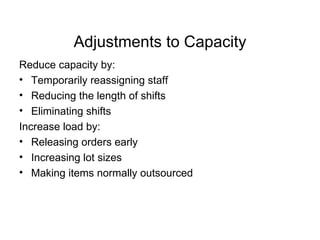

Capacity Requirements Planning (CRP) is a technique to project resource needs for workstations. It takes inputs like planned orders and outputs a load profile for each work center. The load profile compares released orders to work center capacity to identify underloads and overloads. CRP helps determine timing of capacity expansion using strategies like capacity lead, lag, or average. It also provides information to adjust capacity through methods like adding shifts or outsourcing work. The goal is to balance load and capacity to prevent bottlenecks.