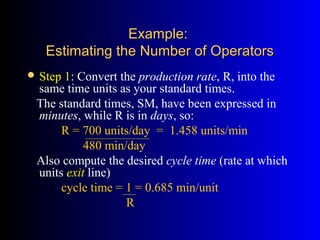

This document discusses techniques for line balancing to meet production goals efficiently. It defines an assembly line as composed of work stations where specific operations are performed. The line must be balanced so work flows evenly between stations. Common approaches to balancing include estimating operator needs and work element sharing between stations. An example problem applies techniques like determining standard times, calculating cycle times, and identifying the slowest station. The goal is to balance workloads across stations while meeting production rate targets.