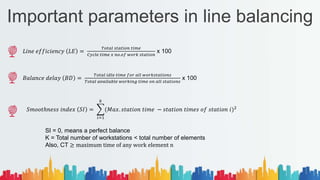

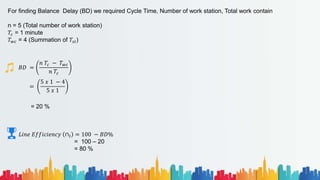

This document provides an overview of industrial engineering topics including line balancing, assembly lines, and progress control. It discusses types of assembly lines like single model, mixed model, and multi model lines. Line balancing aims to distribute work evenly across stations to minimize idle time. Methods like heuristic assignment are used. Progress control monitors production schedules and addresses delays to ensure schedules are met.