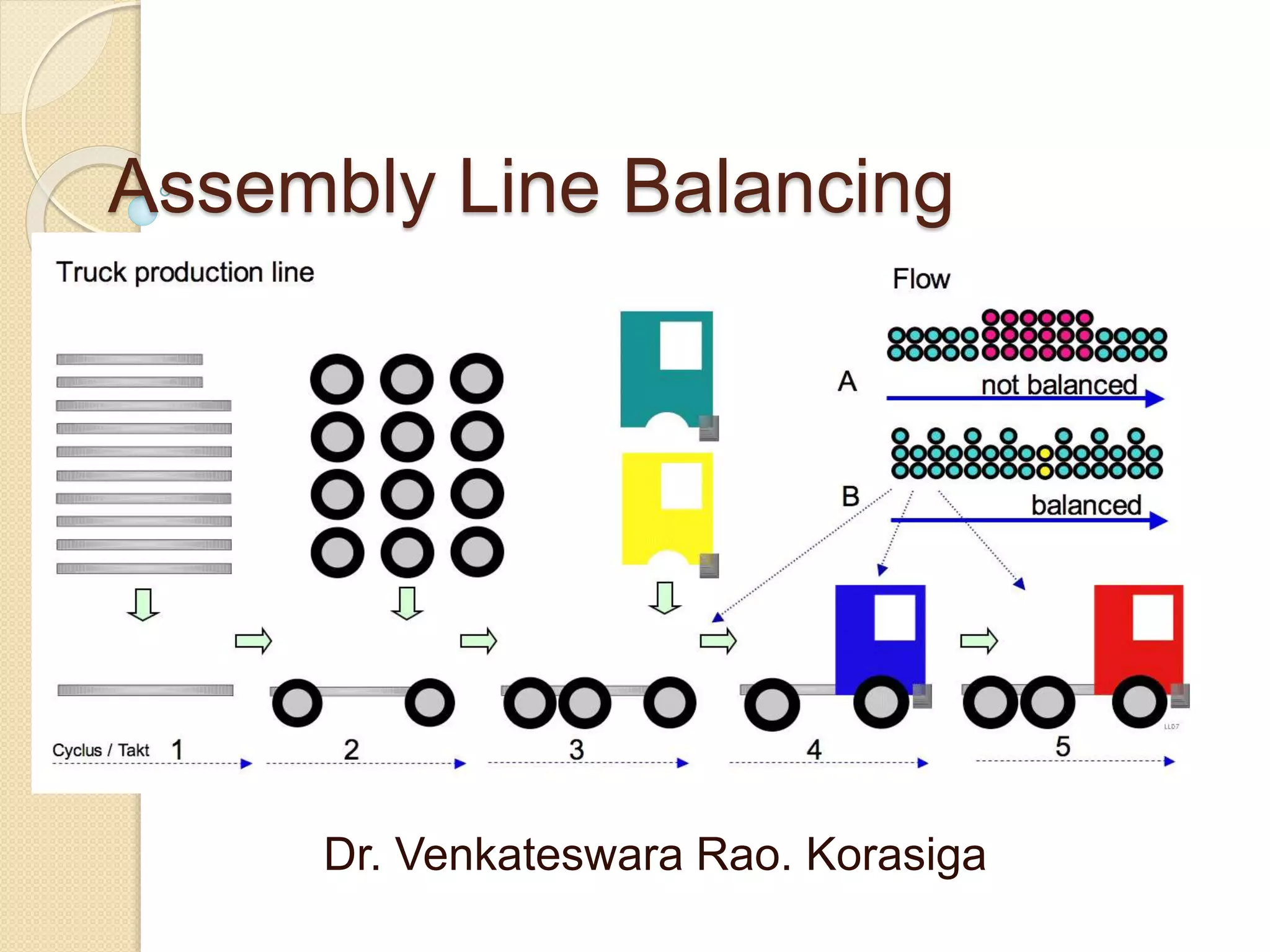

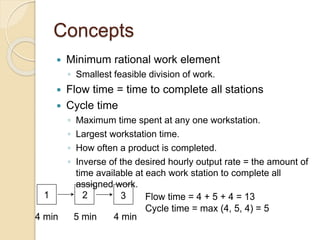

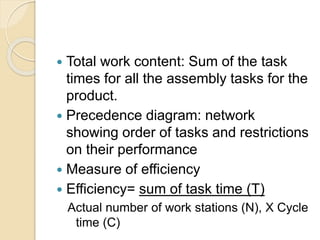

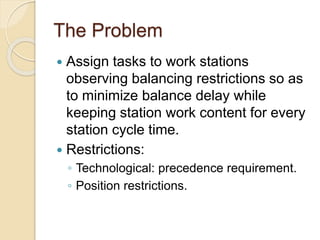

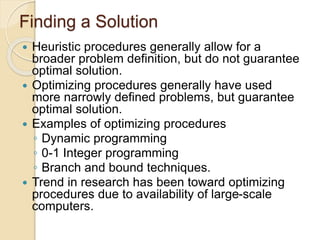

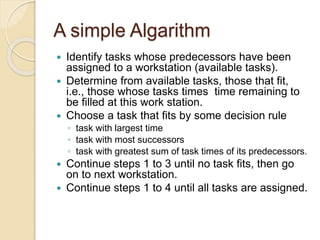

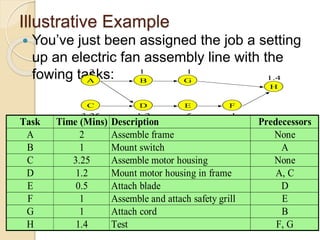

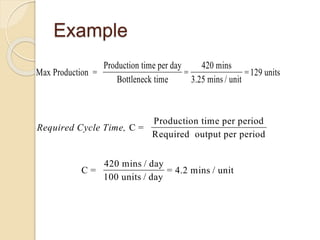

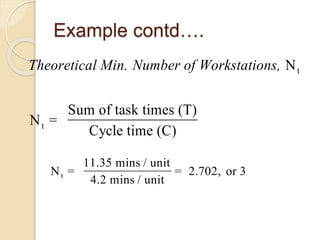

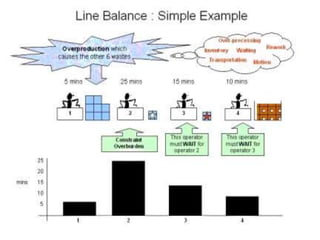

Assembly line balancing is the process of assigning operations to workstations along an assembly line to optimize productivity. The goal is to minimize the number of workstations needed and balance the workload across stations so that no station is overburdened. This balancing of work is important to maximize efficiency and reduce costs, as an optimal assignment can save a company millions per year compared to a suboptimal configuration. Common objectives of line balancing include minimizing cycle times, balancing workloads, and considering operational precedence constraints.