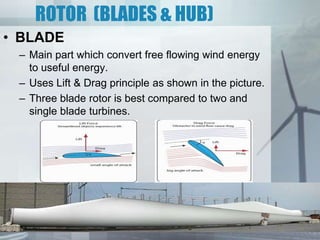

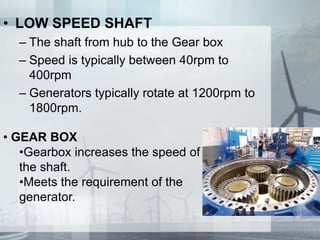

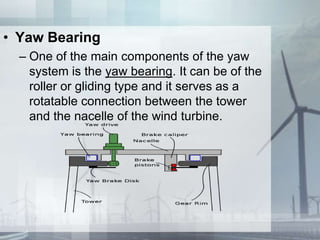

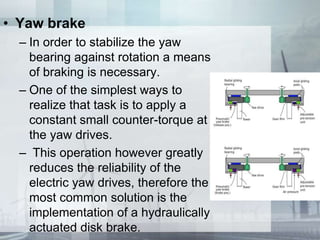

This document provides an overview of the main components of horizontal axis wind turbines (HAWTs), including the rotor, nacelle, yaw system, and tower. It details the functions of each component, such as how blades convert wind energy to mechanical energy and the role of the generator in producing electricity. Additionally, it discusses safety mechanisms like braking systems and the orientation control of the turbine through the yaw system.