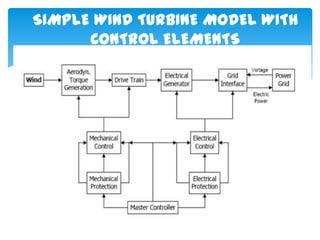

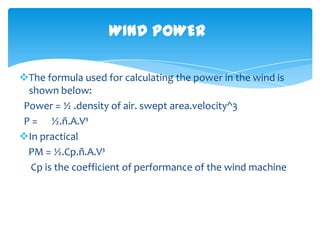

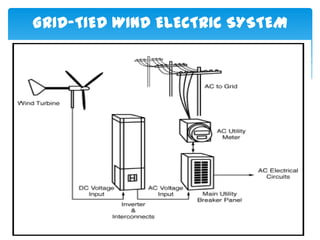

The document summarizes information about wind power and wind turbines. It discusses how wind turbines convert kinetic energy from wind into mechanical or electrical energy. Large wind turbines generate electricity in wind farms, while smaller turbines provide power for homes, farms, and businesses. The key components of a wind turbine include the rotor, gearbox, enclosure, and tail vane. Proper maintenance such as annual inspections and repairs is important to ensure wind turbines operate safely and efficiently for 20-30 years.

![SAFETY CONCERNS

Internal brake and lock

To prevent maximum wind speed- survival

speed [they will not operate above].

Insulation

cold winter conditions, be prepared to de-ice

as required, and store batteries in an insulated

place.

Mounting turbines on rooftops is generally not

recommended](https://image.slidesharecdn.com/gops-windpower-120123112421-phpapp02/85/wind-power-21-320.jpg)