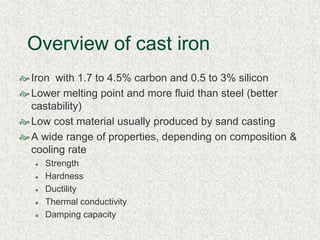

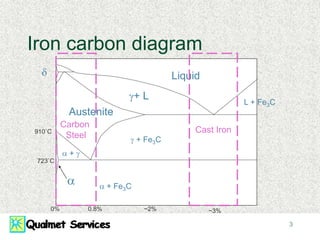

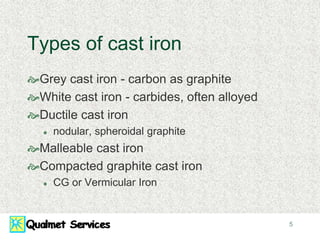

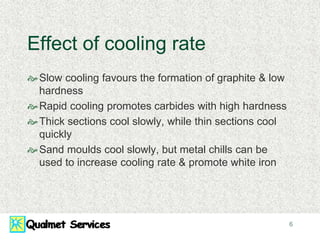

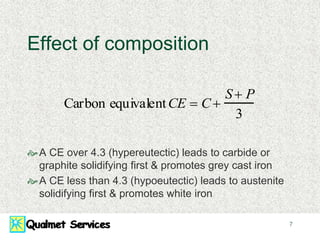

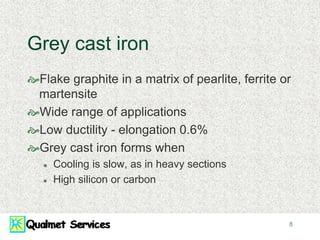

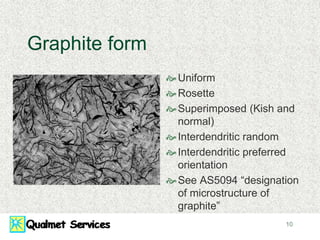

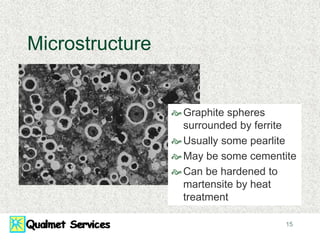

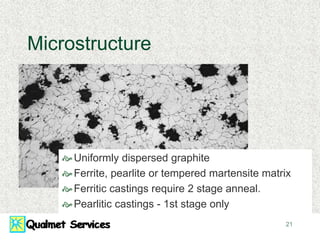

This document provides an overview of cast iron, including its composition, production methods, types, microstructures, properties and applications. It discusses grey cast iron which forms graphite flakes and has a wide range of properties depending on its composition and cooling rate. It also covers ductile and malleable cast iron which form spheroidal graphite nodules providing better ductility than grey cast iron. White cast iron is discussed which forms carbides rather than graphite and is often alloyed for abrasion resistance. The effects of composition, cooling rate, heat treatments and microstructures on the properties of different cast iron types are summarized.