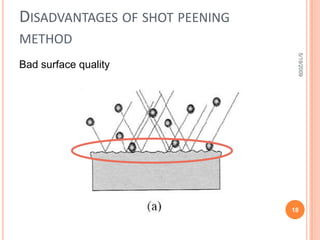

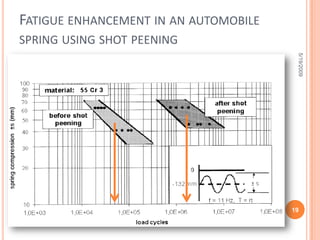

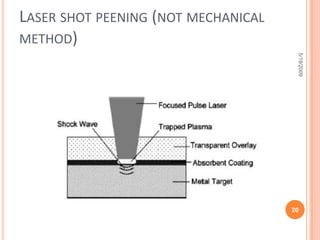

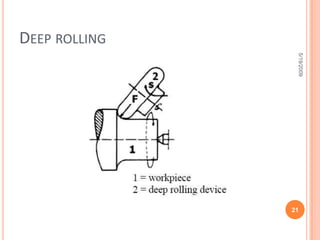

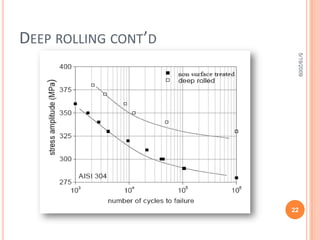

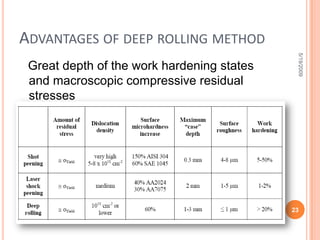

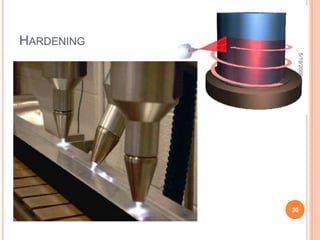

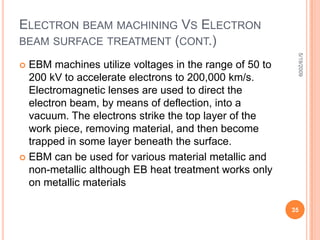

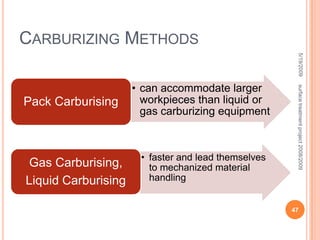

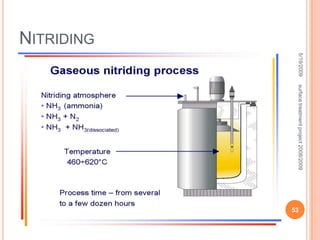

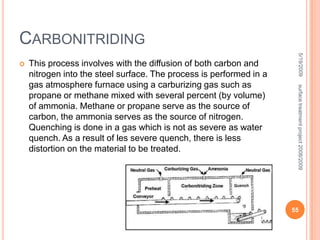

This document summarizes various surface treatment techniques including mechanical processes like shot peening and deep rolling that modify the surface without changing chemistry, thermal processes like electron beam treatment and laser treatment, and thermo-chemical processes like carburizing, nitriding, and carbonitriding that diffuse elements like carbon or nitrogen into the surface. It provides details on the mechanisms, advantages, and applications of these different surface modification methods.