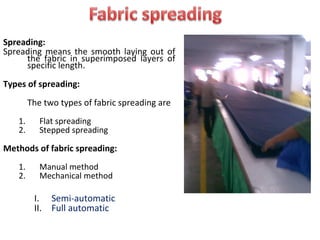

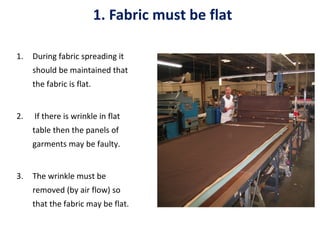

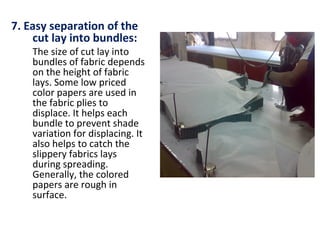

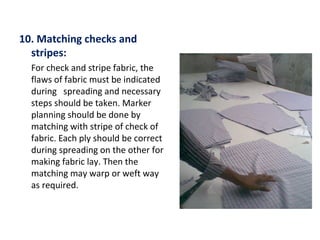

The document discusses the process of fabric spreading in garment manufacturing. It explains that fabric spreading involves the smooth laying out of fabric layers of a specific length, which can be done through flat or stepped spreading. There are 10 key requirements for proper fabric spreading, including maintaining the fabric's flatness, applying uniform tension, aligning fabric layers, and matching patterns like checks and stripes. The document also outlines different manual and mechanical methods for fabric spreading.