Embed presentation

Download to read offline

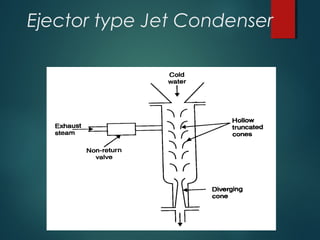

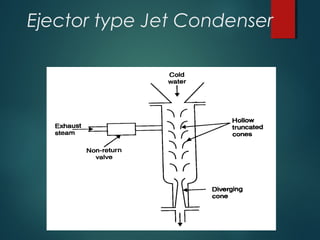

This document discusses different types of steam condensers. It describes jet condensers, which mix steam and coolant water, and non-mixing surface condensers, where steam passes over tubes containing coolant water. Surface condensers can be single-pass or multi-pass designs. The document also notes reasons for inefficiency in surface condensers, such as air leaks and heat conduction issues. It provides a comparison of jet and surface condensers, noting their differences in construction, maintenance needs, space requirements, and suitability for plant capacity.