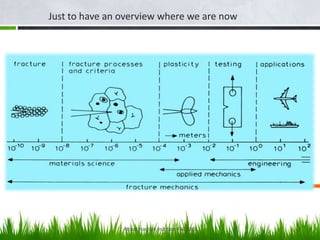

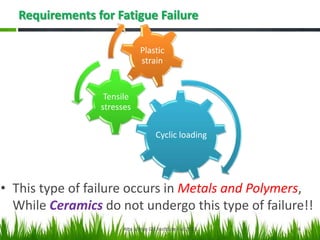

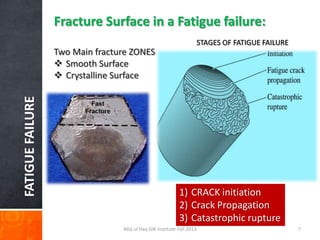

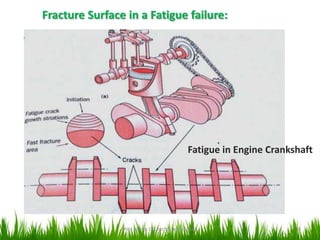

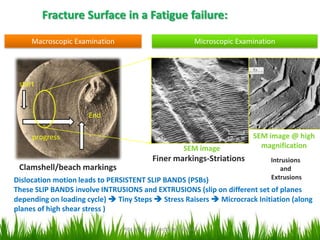

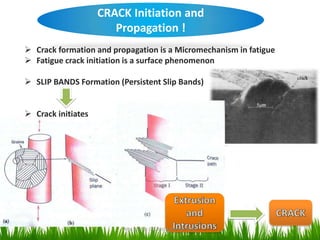

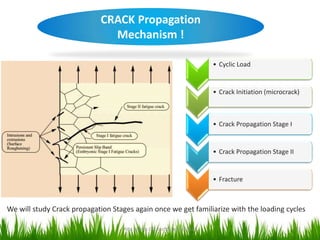

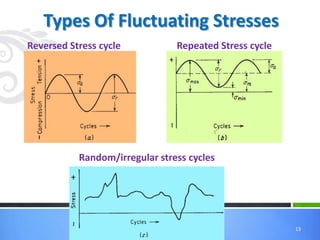

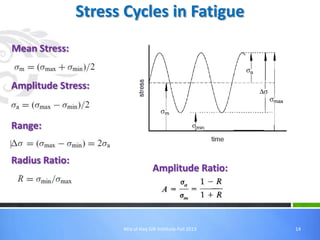

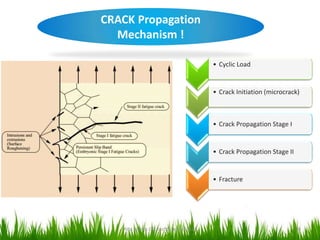

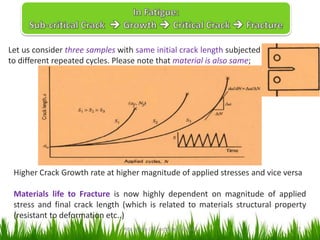

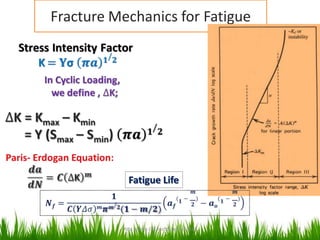

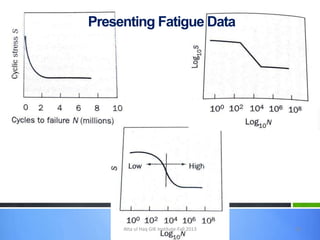

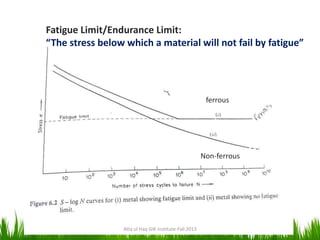

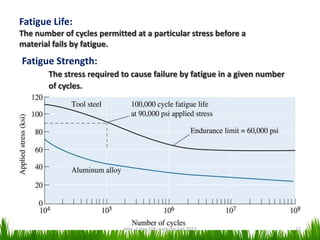

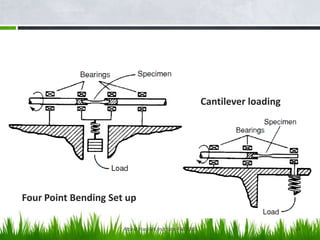

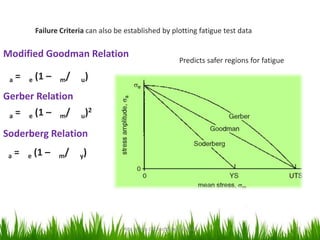

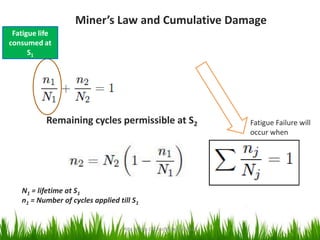

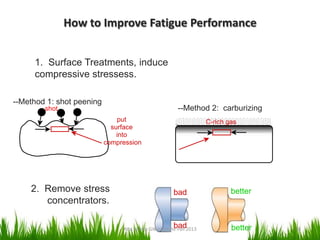

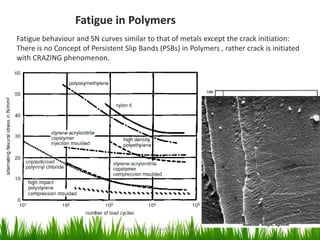

This document provides an overview of fatigue failure. It begins by defining fatigue as the premature failure or lowering of strength of a material due to repetitive stresses, even if they are below the material's yield strength. It then discusses key topics in fatigue such as stress cycles, S-N curves, fatigue testing, and factors that affect fatigue life. Crack initiation and propagation stages are described. Methods for improving fatigue performance, such as shot peening and removing stress concentrators, are also covered.