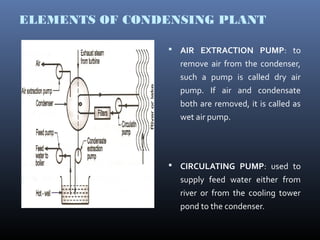

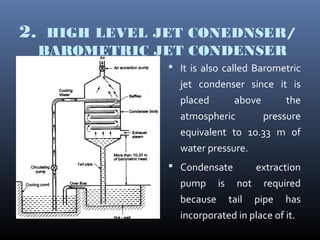

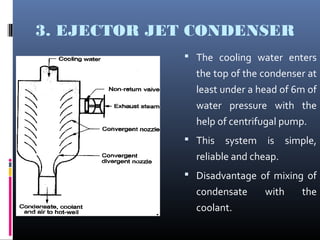

This document provides information about Achal Patel, a mechanical engineering student, and discusses steam condensation and different types of condensers. It defines steam condensation as when steam pressure drops below atmospheric pressure such that its energy cannot be fully reused. It describes a steam condenser as a heat transfer device that condenses exhaust steam using cooling water at below atmospheric pressure. It lists advantages of condensation including increased work output, reduced steam consumption, smaller power plants, improved efficiency, and lower water costs. It outlines elements of condensing plants, such as air extraction pumps and circulating pumps. It categorizes condensers into jet and surface condensers and describes various jet and surface condenser types.