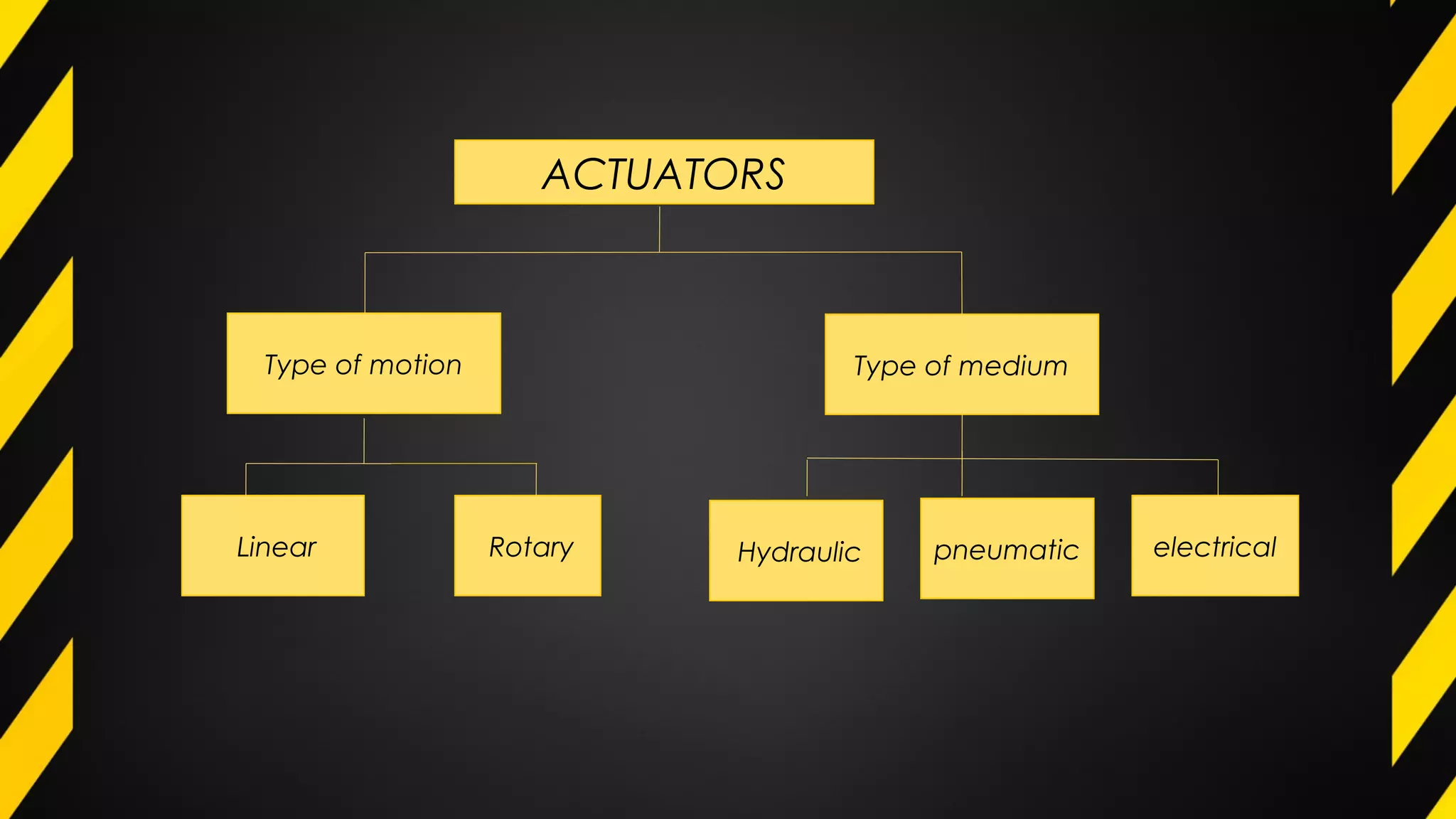

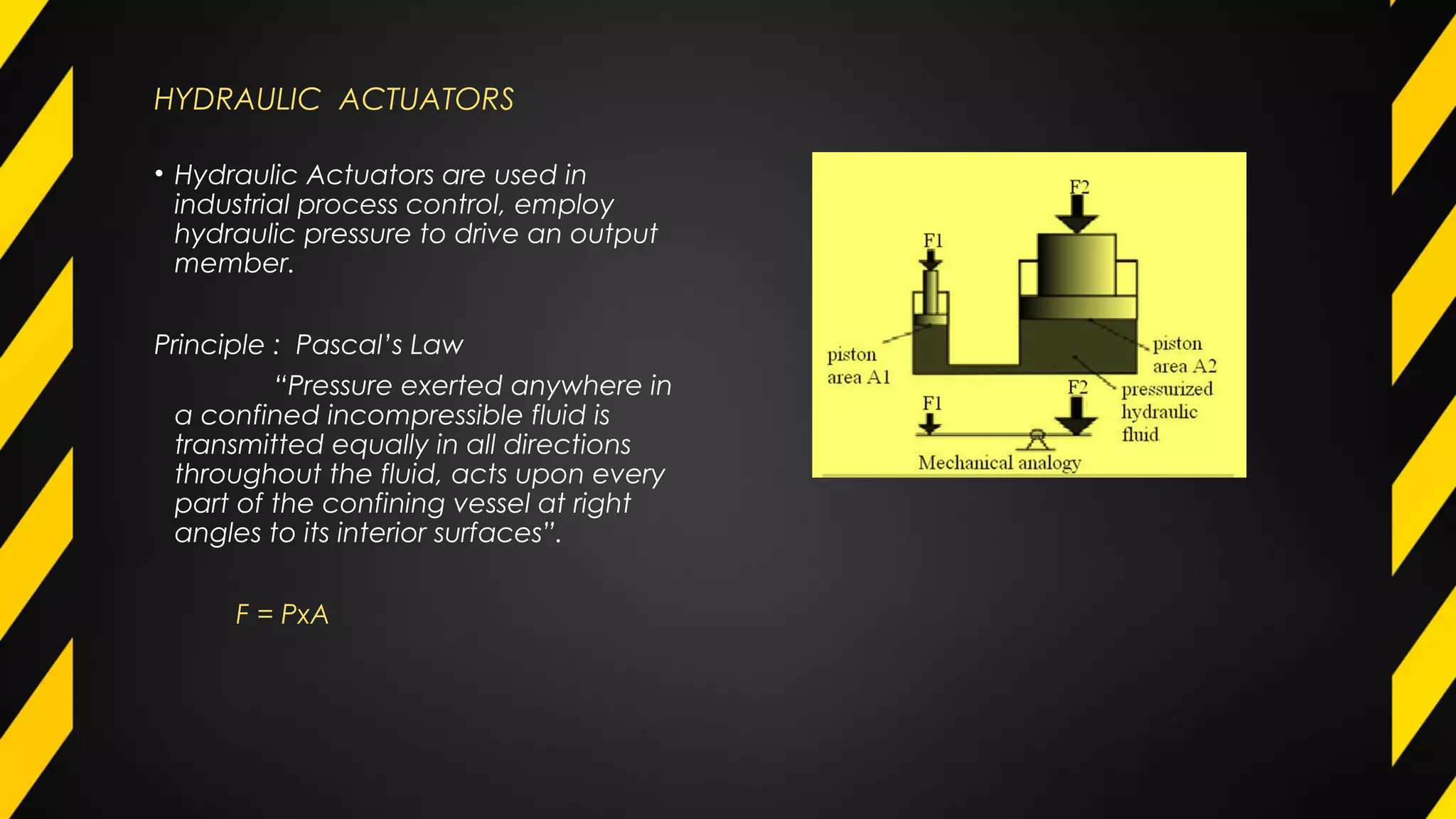

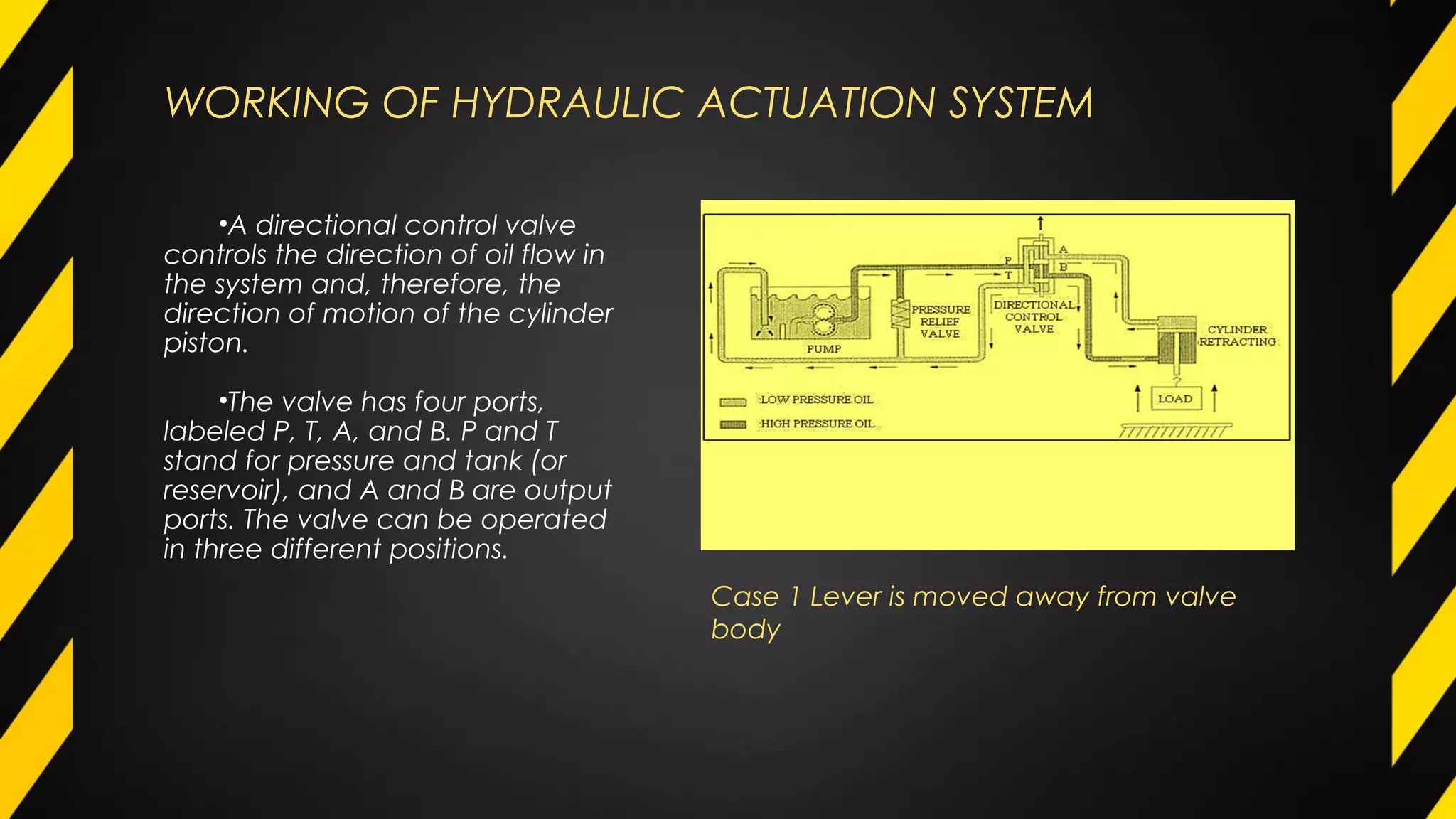

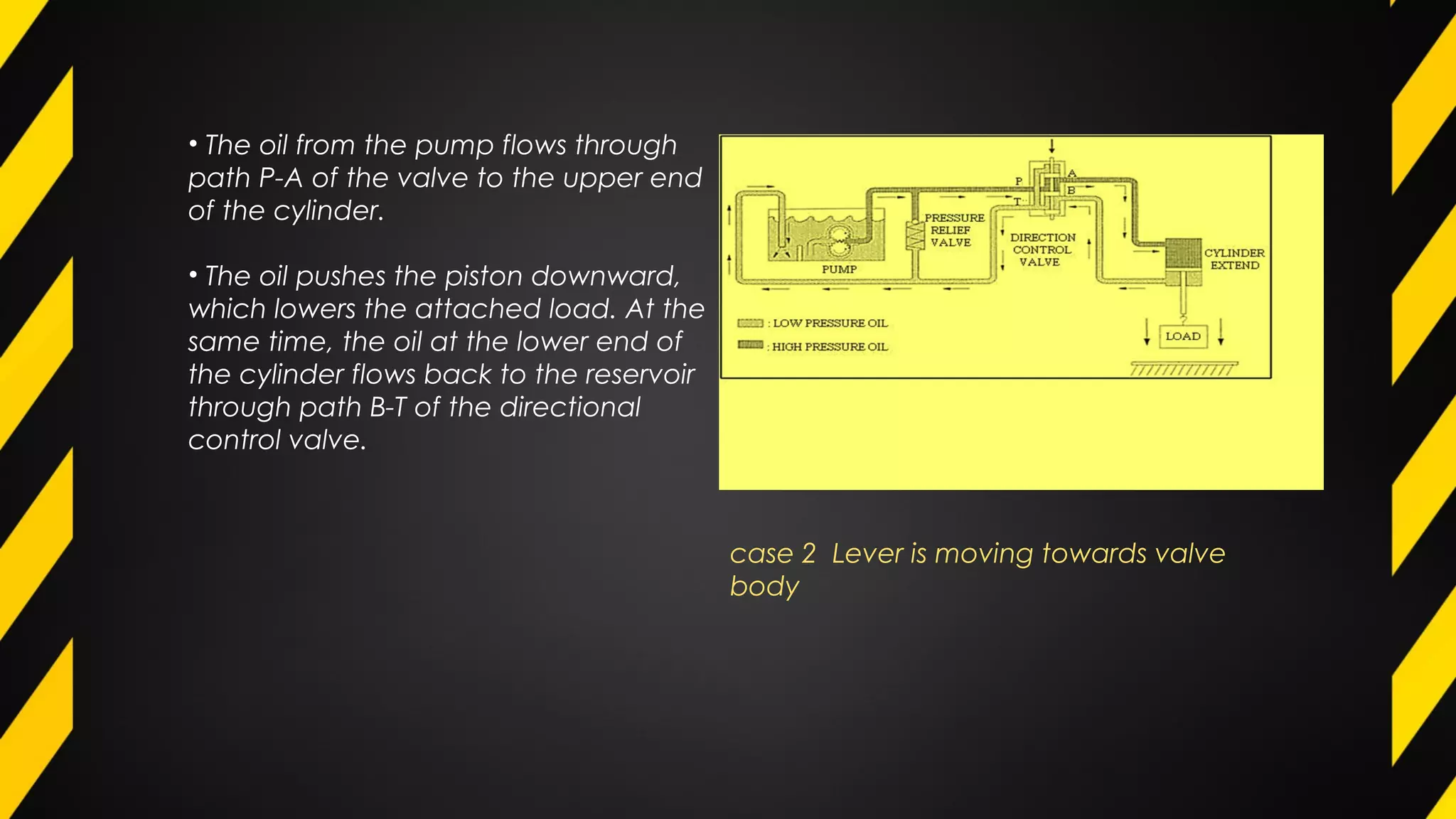

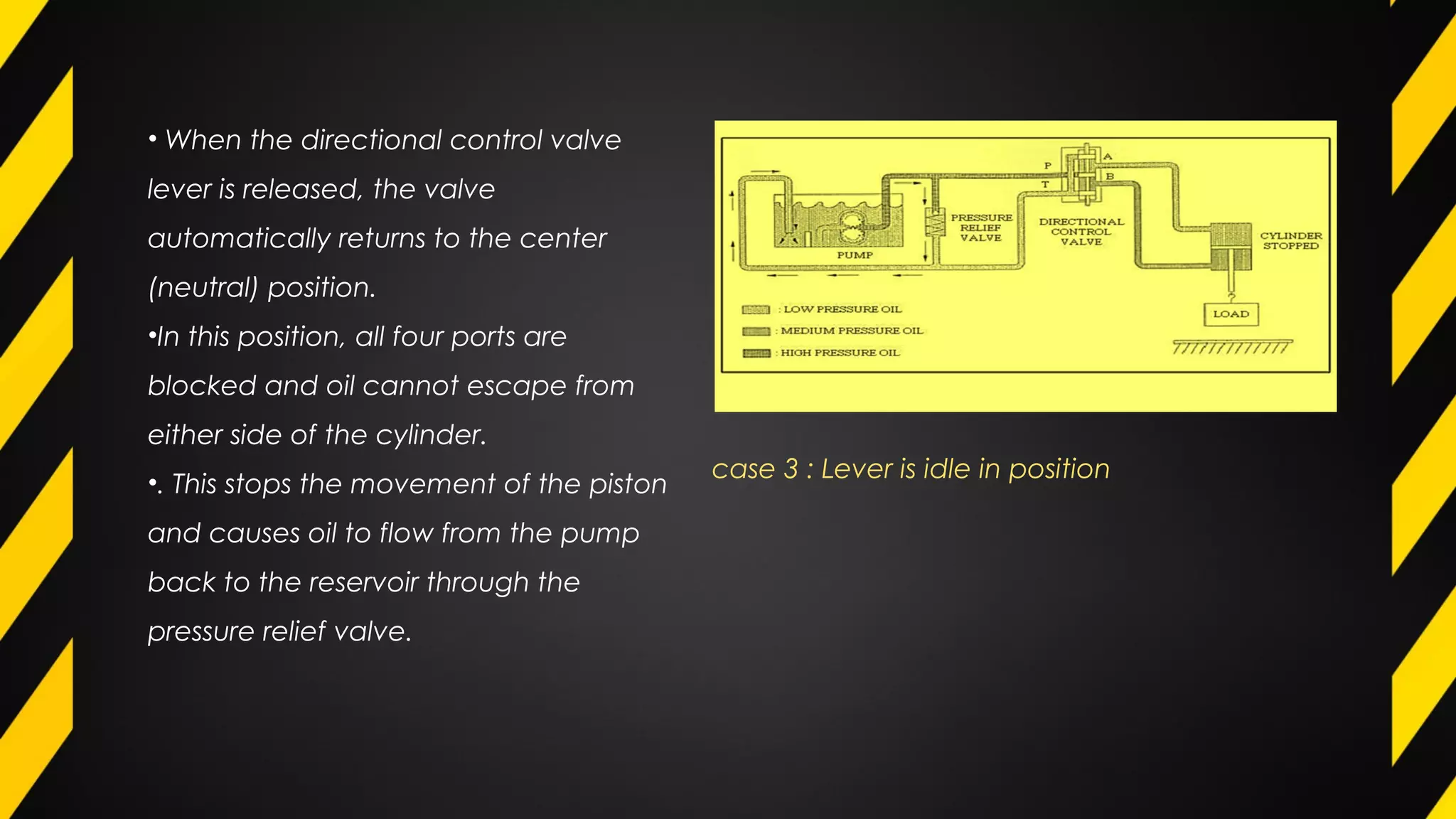

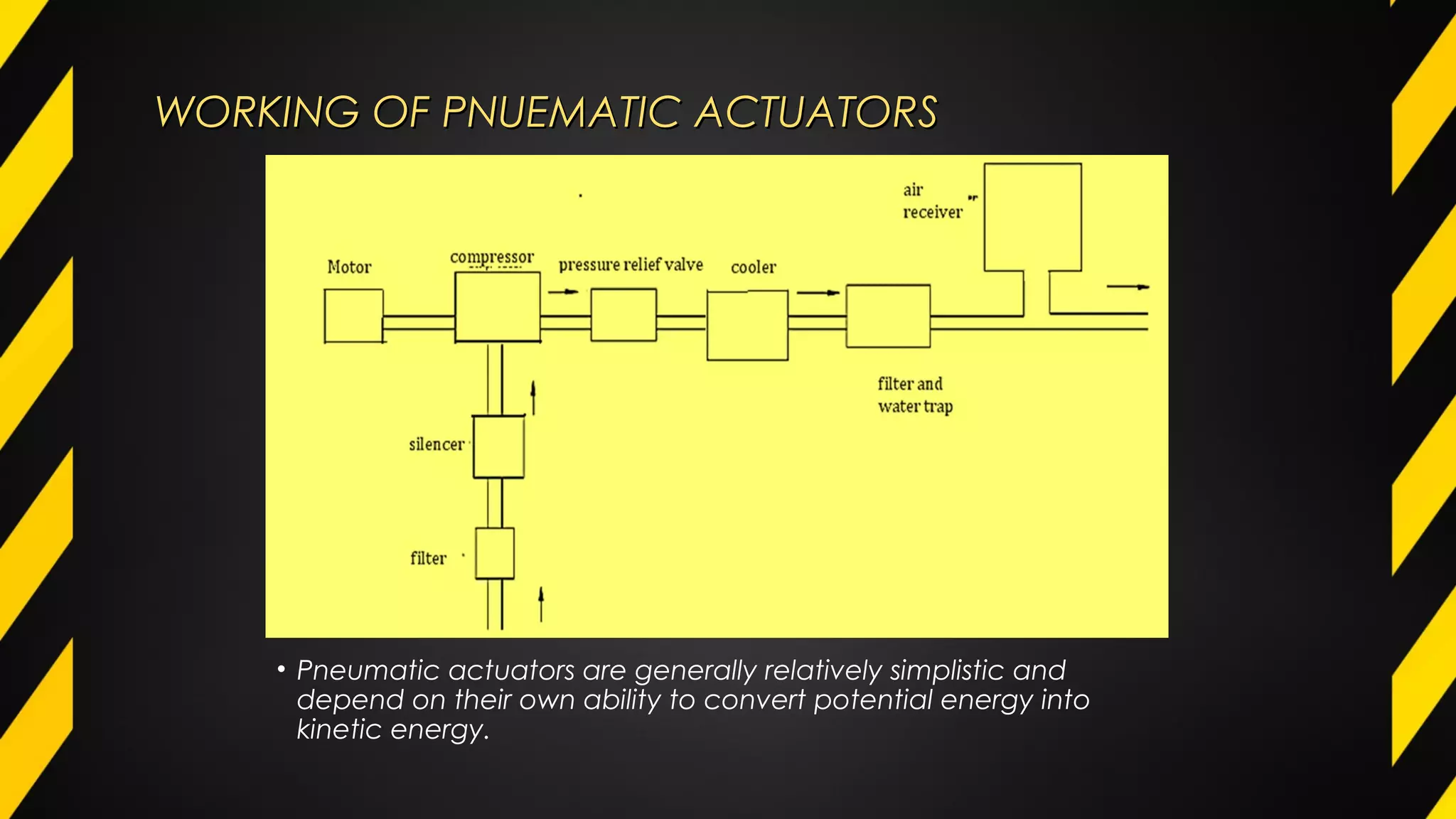

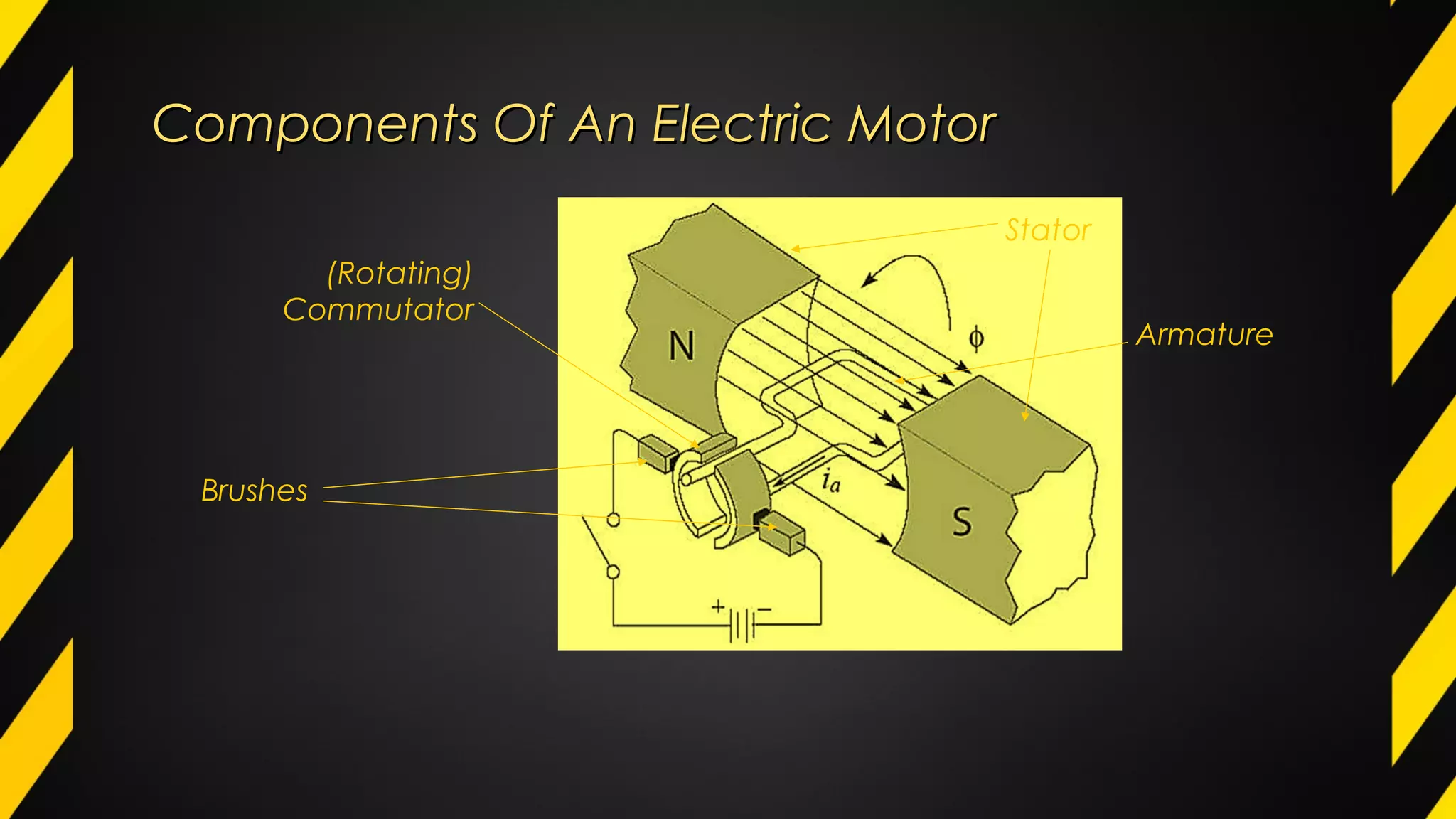

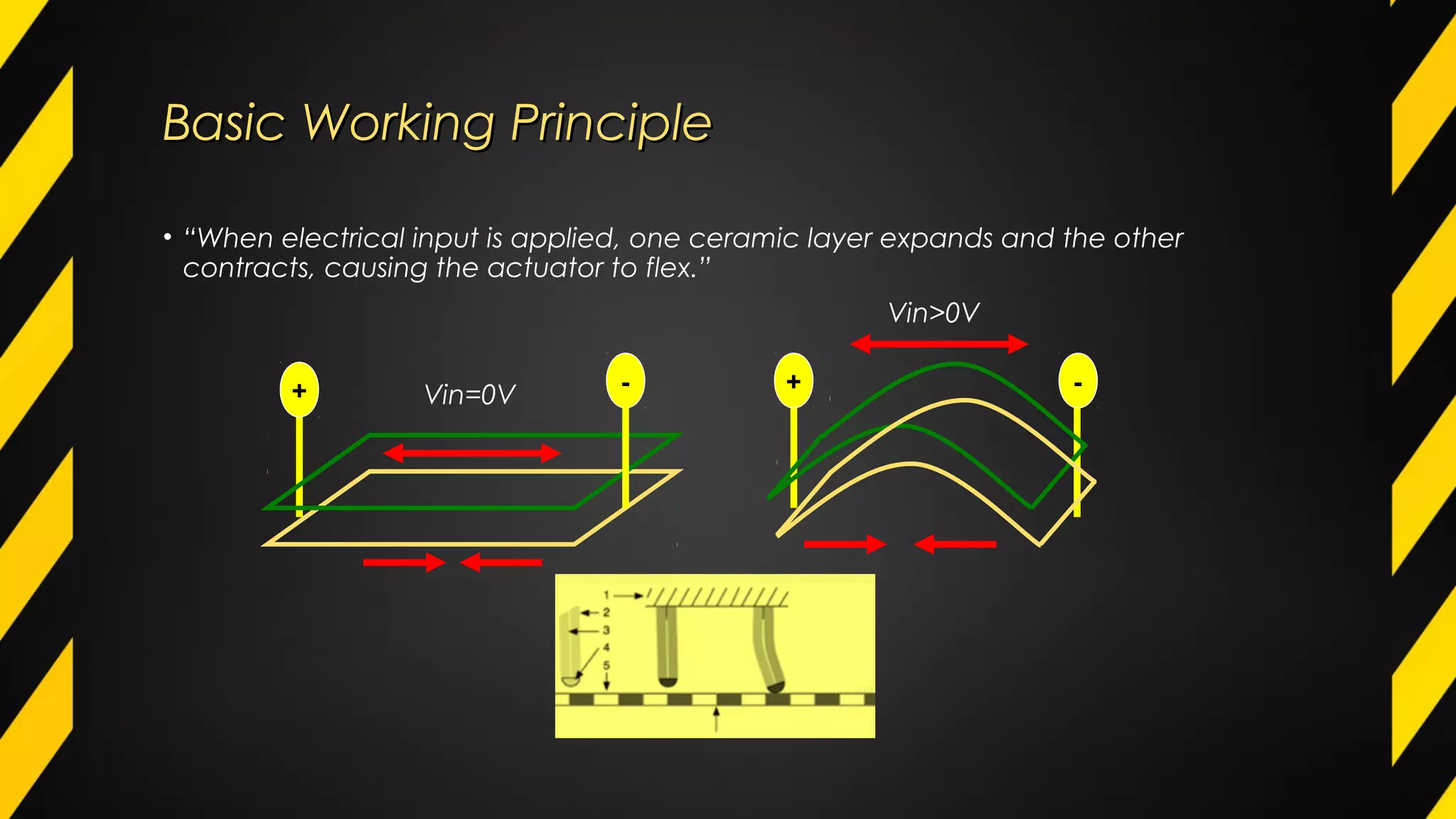

The document describes various types of actuators including hydraulic, pneumatic, electric, piezoelectric, and MEMS actuators, detailing their working principles and components. Hydraulic actuators rely on fluid pressure controlled by valves to create motion, while pneumatic actuators convert compressed air into motion. Electric motors operate based on electromagnetic principles, with subtypes like piezoelectric motors utilizing material deformation for movement.