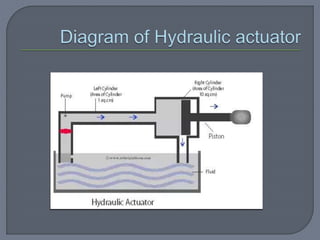

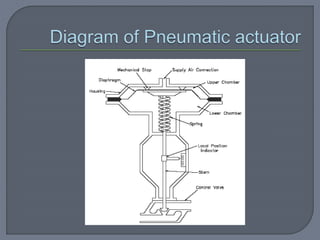

This document discusses different types of actuators. It describes linear actuators which produce straight line motion and rotary actuators which produce rotational motion. Some common types of actuators mentioned are hydraulic, pneumatic, mechanical, electrical, and piezoelectric actuators. Hydraulic actuators use pressurized fluids to produce motion and can generate high forces but require external pumps. Pneumatic actuators use compressed air and are low cost with high speed but have limited pressure ranges. Mechanical actuators directly convert motion without additional power sources. Electric actuators include DC motors, AC motors and stepper motors. Piezoelectric actuators use crystals that deform with applied electric fields to produce small, precise motions.