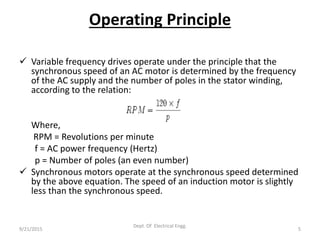

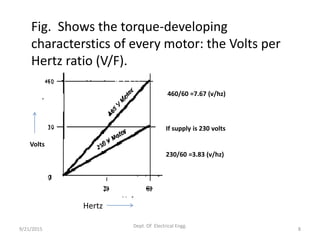

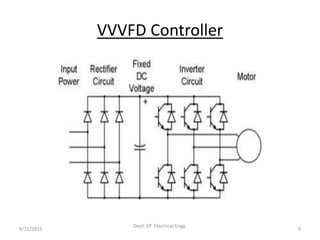

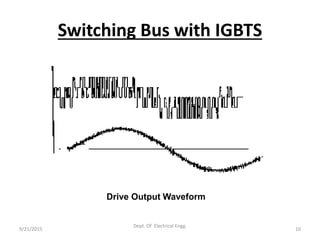

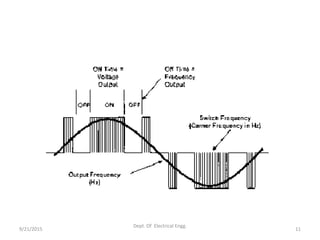

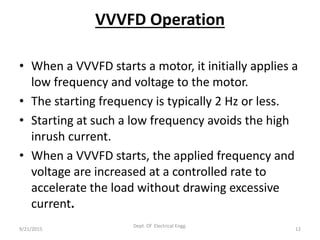

This document discusses variable voltage and variable frequency drives (VVVFD). It begins with an introduction that defines a VVVFD as a system that controls the rotational speed of an AC motor by controlling the frequency of the electrical power supplied. It then discusses operating principles such as how motor speed is determined by supply frequency. The document also describes the components of a VVVFD system including the controller and operation, noting it initially applies low frequency and voltage to avoid high inrush current. In conclusion, it states AC drives like VVVFDs are replacing DC motors in some applications due to advantages like automatic control.