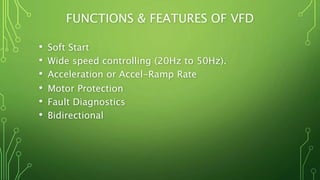

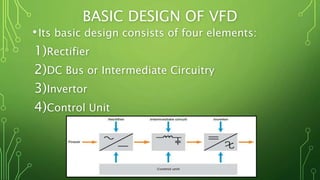

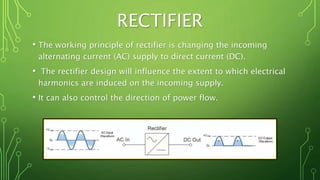

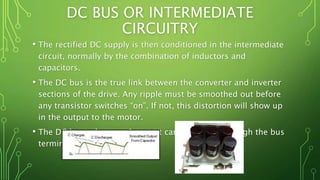

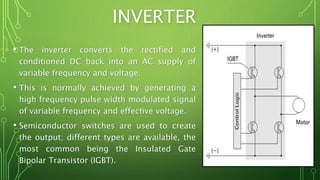

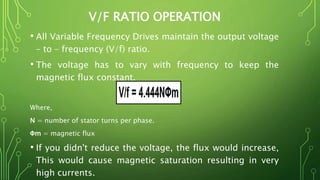

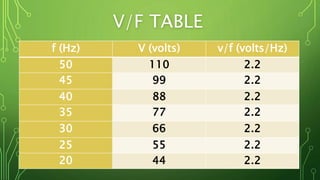

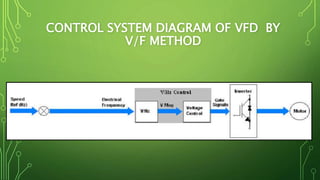

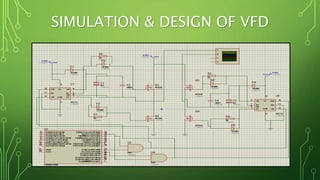

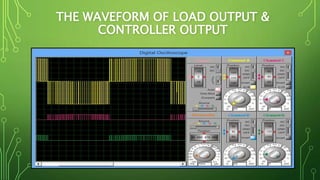

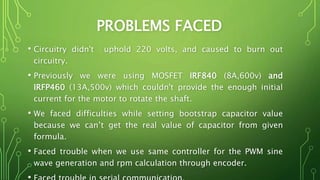

The document describes a variable frequency drive (VFD) created by engineering students to control the speed of a single-phase induction motor. The VFD uses a microcontroller to generate pulse width modulation for an inverter that varies the frequency and voltage supplied to the motor. The students faced issues with components not supplying enough current and burning out. They overcame these by replacing mosfets with higher capacity IGBTs, lowering the input voltage, and trial-and-error tuning of circuit elements. The VFD allows control and energy savings compared to a fixed speed motor.