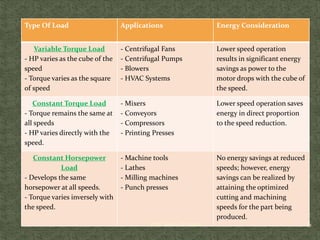

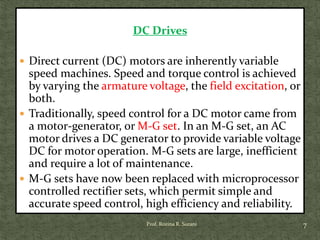

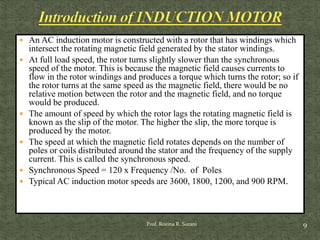

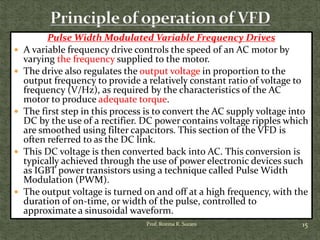

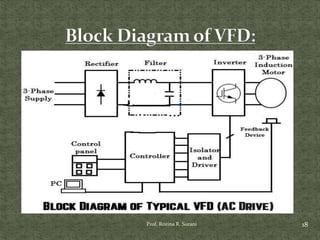

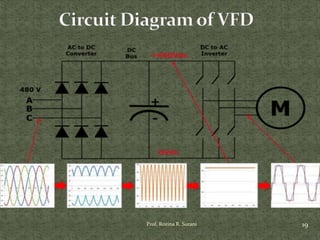

A variable frequency drive (VFD) controls the speed of AC motors by adjusting both the voltage and frequency supplied to the motor. This allows for continuous speed control as opposed to discrete speeds from gearboxes. VFDs improve efficiency by matching the motor speed to the required process demands. They provide benefits like energy savings, improved power factor, soft starting and stopping of motors, and elimination of mechanical drive components. The document then discusses different types of motor loads and applications that can benefit from VFDs before explaining how pulse width modulation VFDs work by converting AC power to DC, and then back to AC with a controlled frequency.