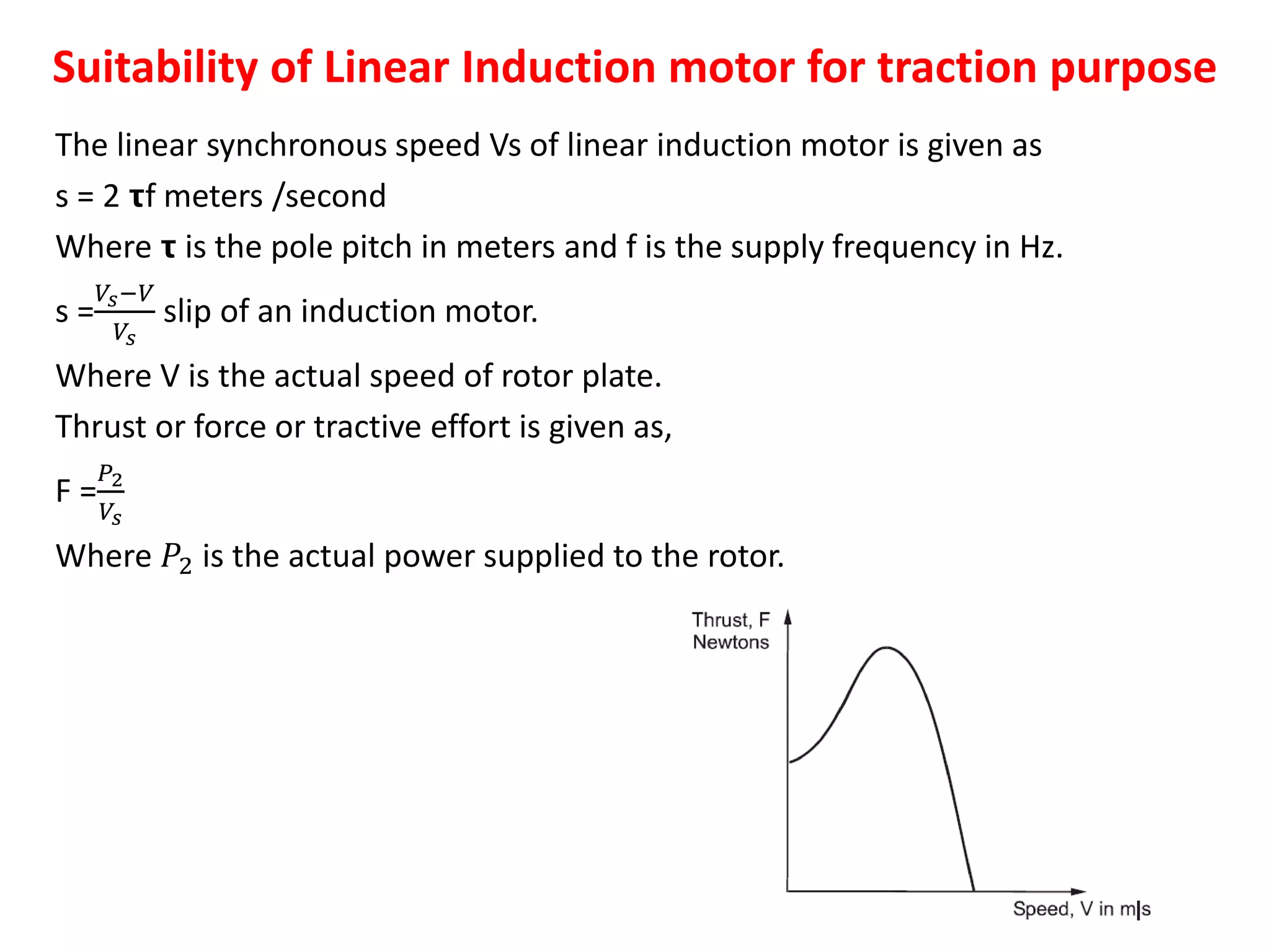

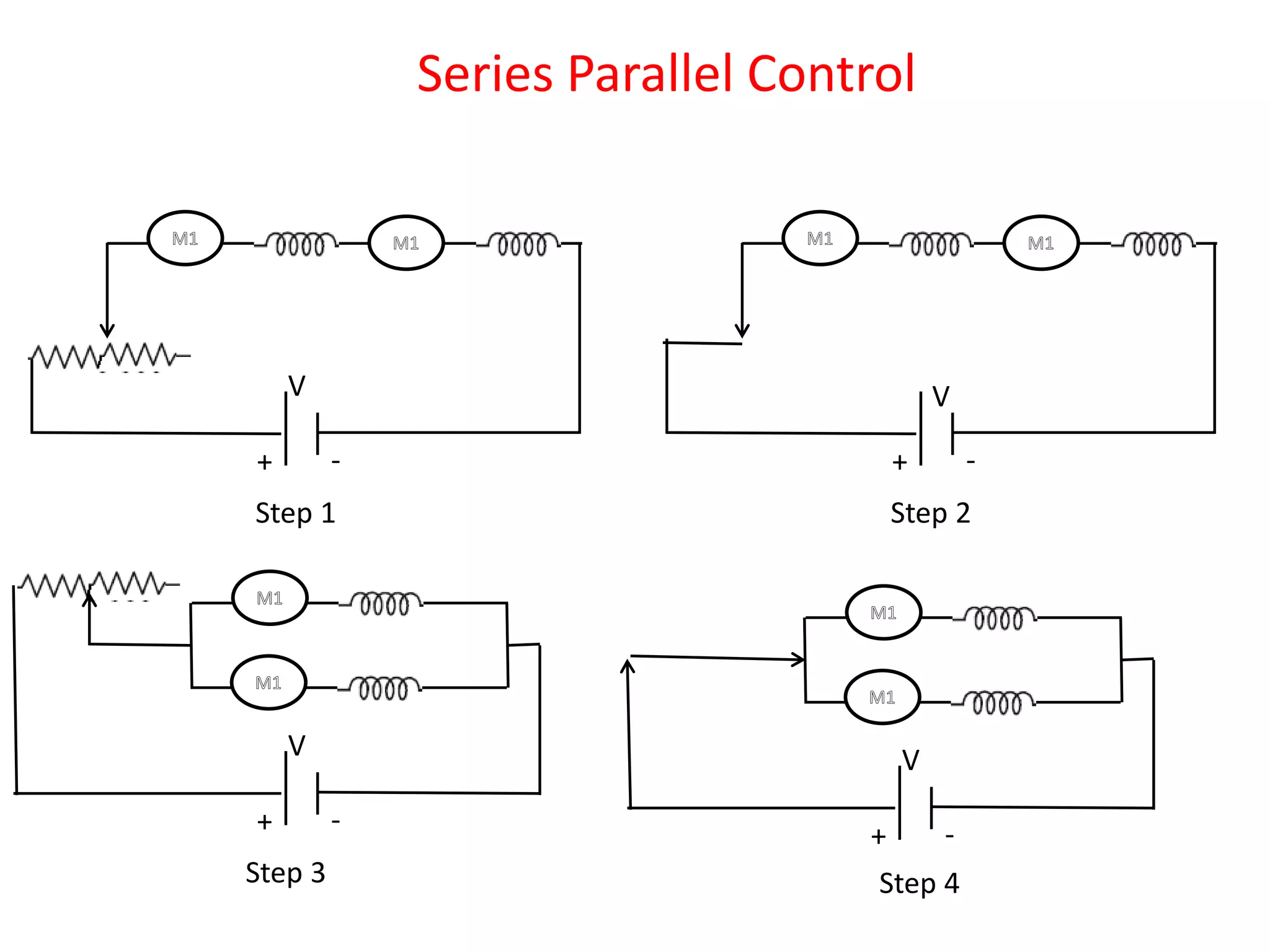

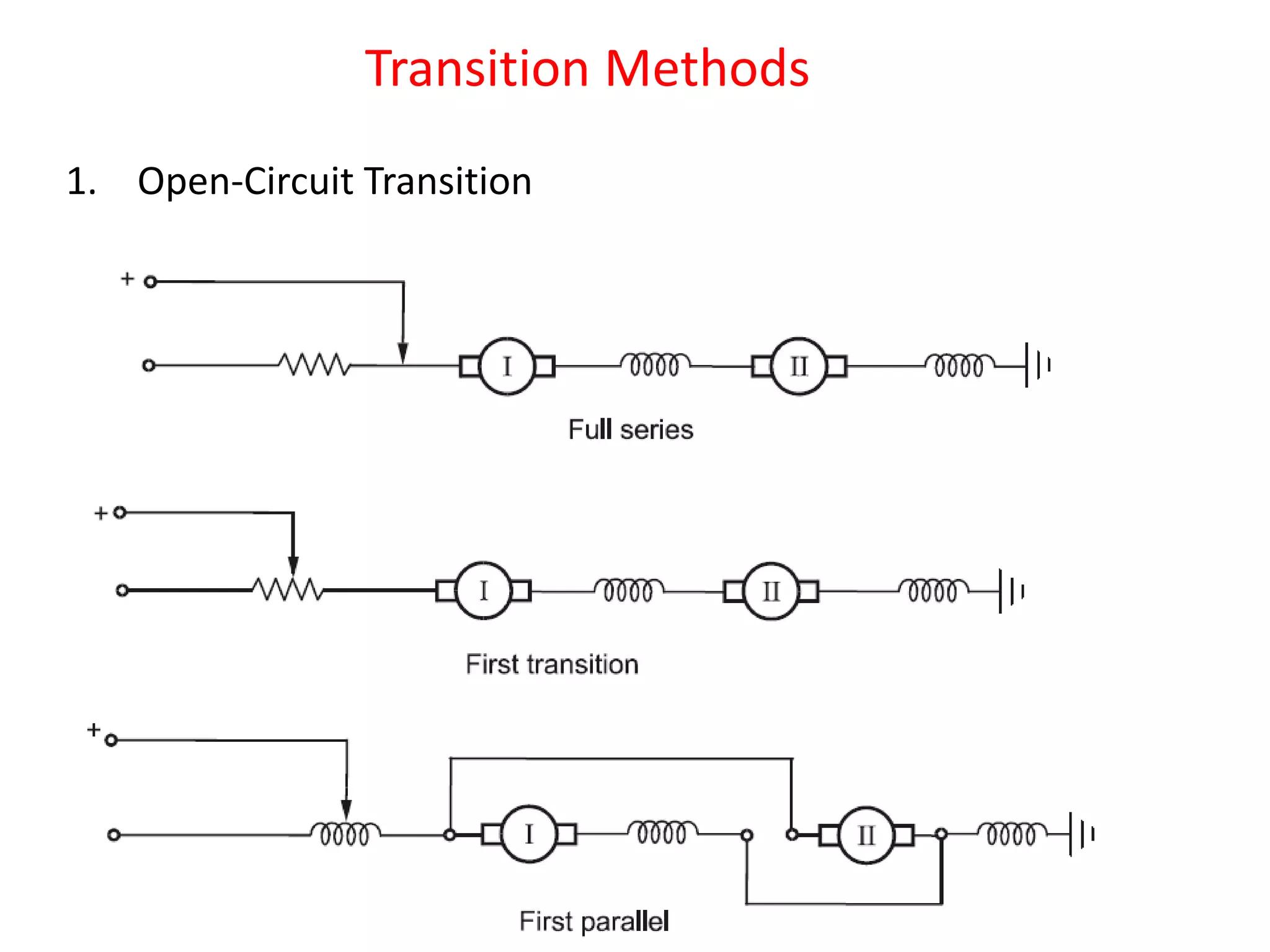

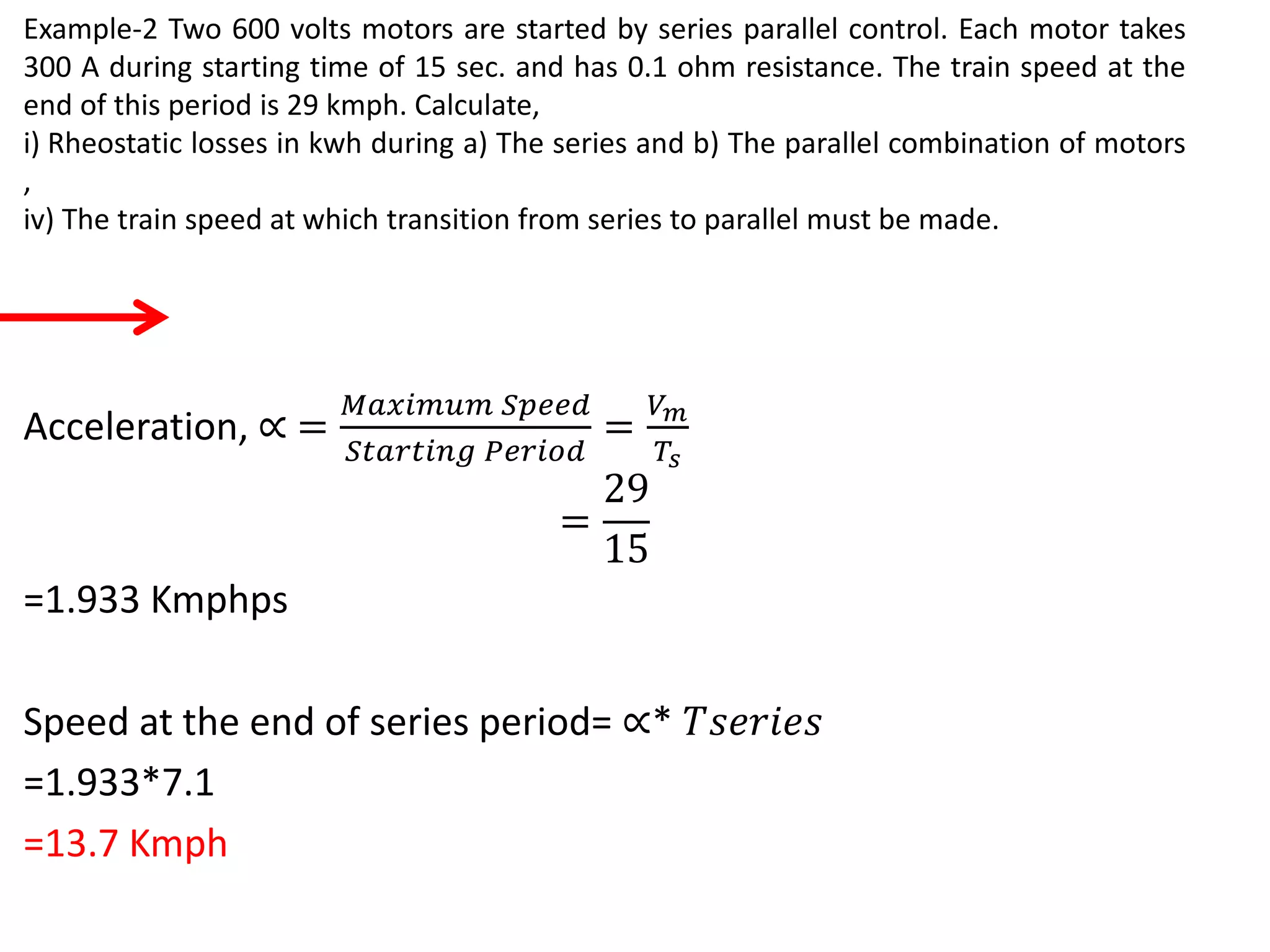

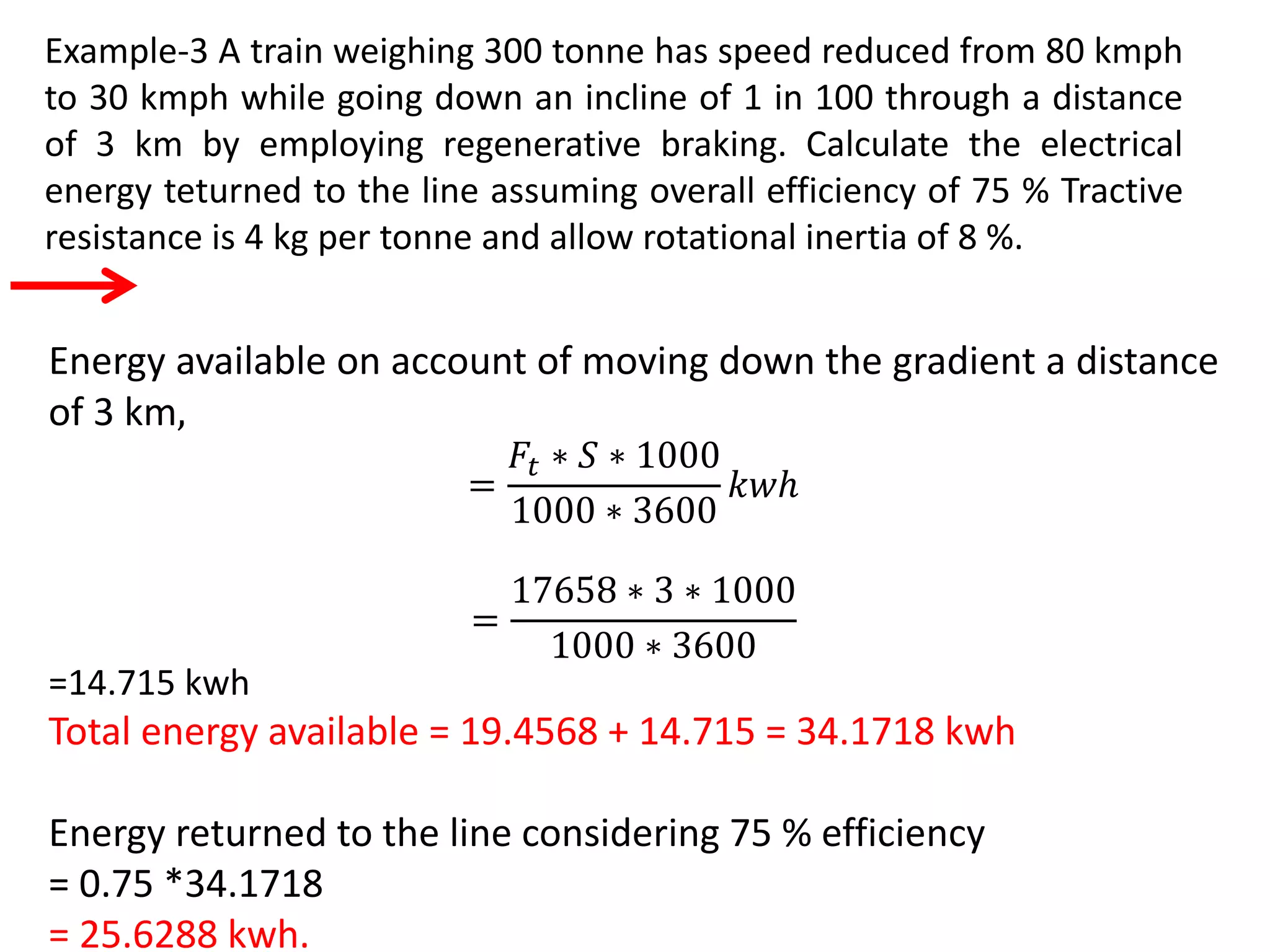

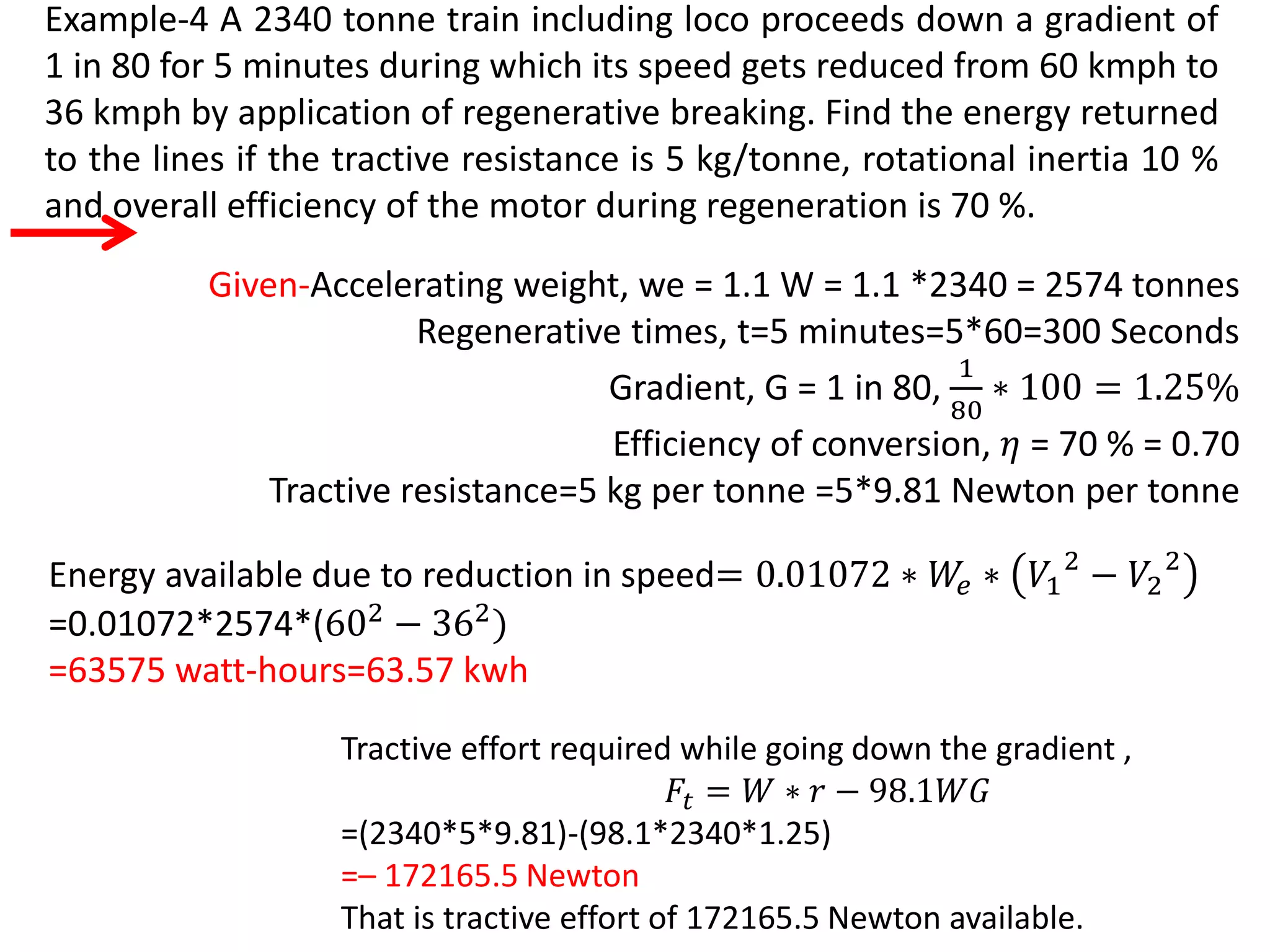

This document discusses traction motors and their control. It describes the desirable characteristics of traction motors, including high starting torque, simple speed control, and self-relieving properties. It evaluates the suitability of DC series motors, AC series motors, and linear induction motors for traction applications. It also examines speed control methods for DC traction motors like series parallel control, transition methods, regenerative braking, and the self-relieving property of DC series motors. Numerical examples are provided on series parallel control and regenerative braking.