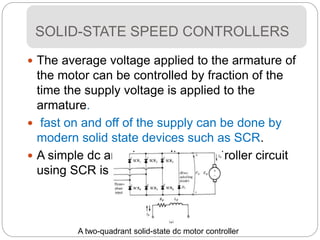

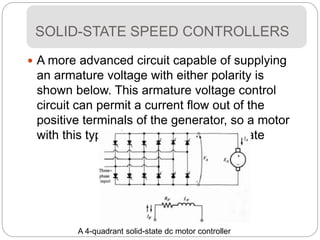

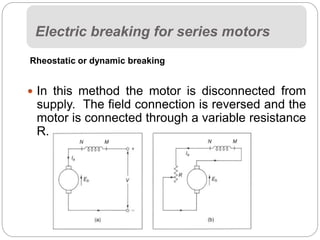

The document discusses DC motor starters, breaking methods, and speed control. It describes how starting resistors are used to limit excess starting currents in DC motors. Ward-Leonard and solid-state speed control systems are introduced that vary the motor's armature voltage to control speed. Three methods of electric braking for DC motors are covered: rheostatic, plugging, and regenerative braking.