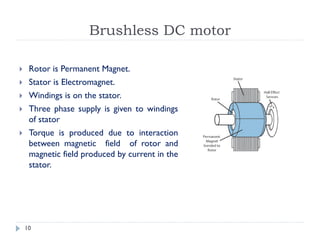

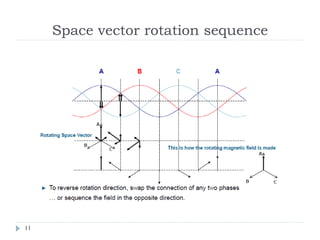

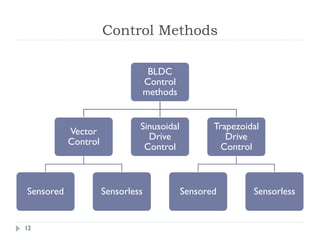

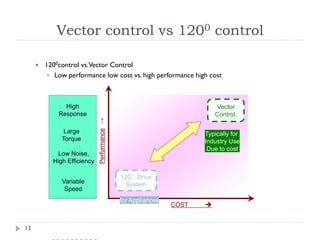

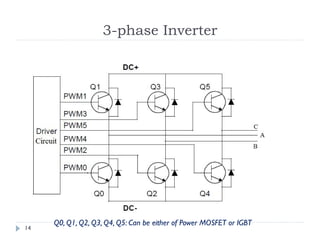

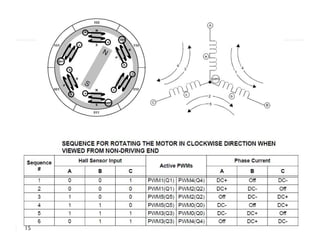

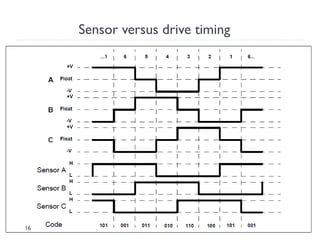

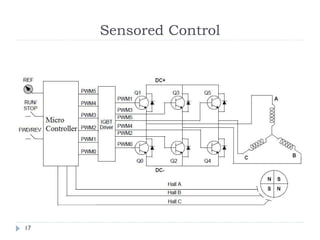

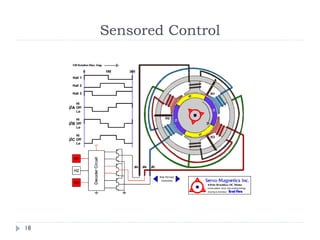

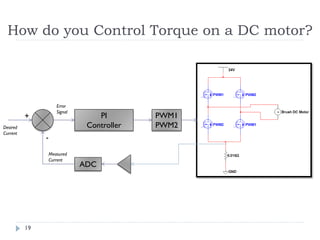

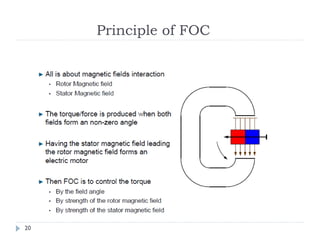

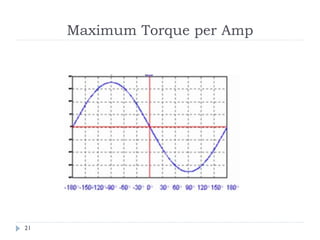

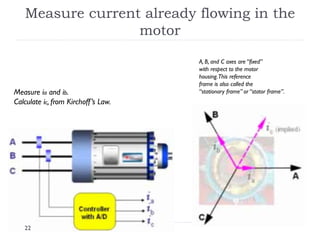

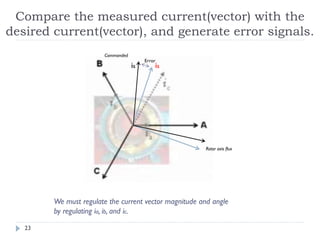

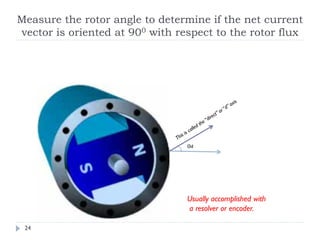

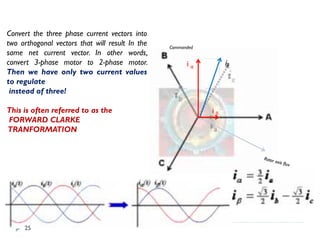

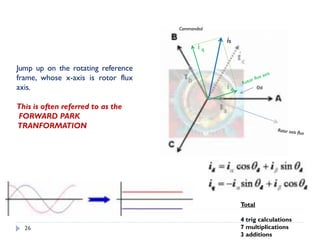

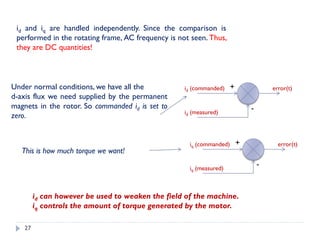

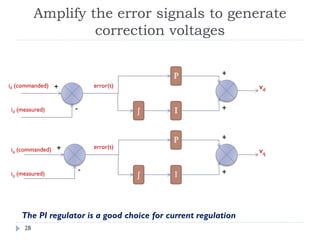

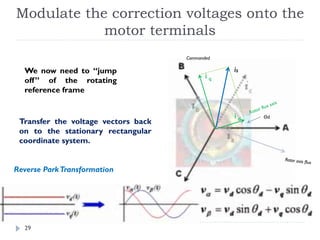

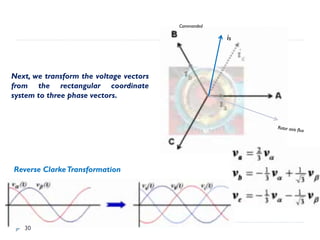

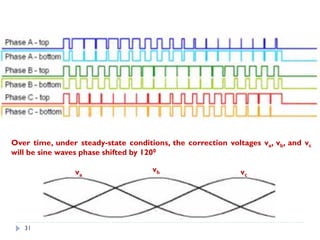

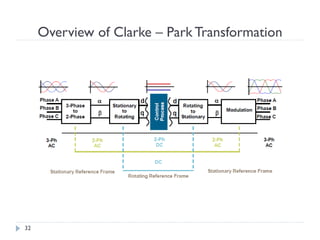

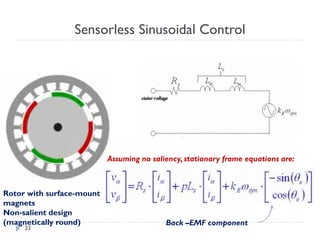

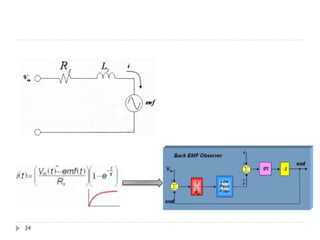

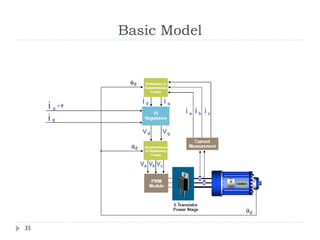

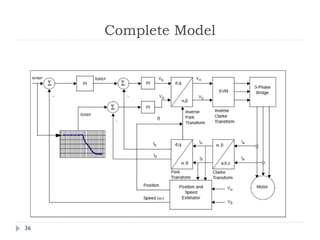

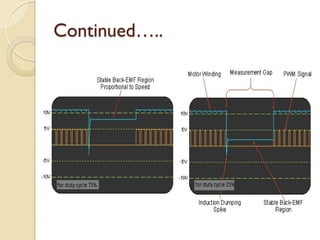

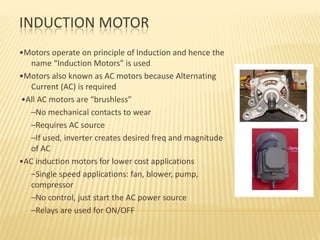

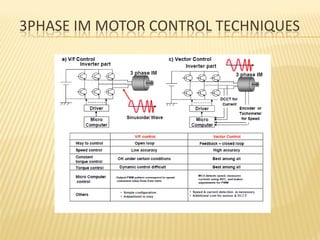

This document summarizes a study on vector control algorithms and inverter design for BLDC motors. It discusses the objectives of studying BLDC motor operation, different control algorithms including vector control, and inverter design. It also covers V/F control of induction motors. Key topics covered include Clarke/Park transformations, sensorless control, inverter topologies, and a comparison of vector and V/F control techniques. The document is authored by engineering students and provides an overview of various motor control concepts and algorithms.