DC machines can achieve wide range speed control through three main methods - armature resistance control to vary speed below base speed, field flux control to vary speed above base speed, and armature voltage control using systems like Ward-Leonard which combine armature and field control to achieve the widest speed range from below to above base speed. Controlled rectifiers and series-parallel configurations are also used to vary armature voltage for smooth speed regulation.

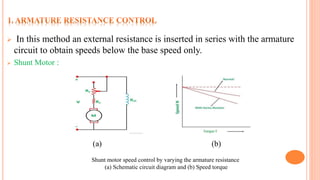

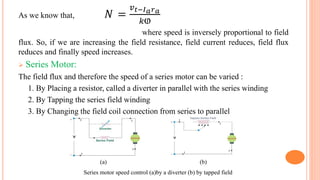

![ Series Motor:

(a) (b)

For the wide range of speed ,this method is usually carried out. Similar is the case as earlier

discussed in shunt motor, it has the speed below base speed.

Applications: Series motor driving Cranes, Hoists, Trains etc.

NOTE: In both the motors, field flux remains constant where armature current is maintained

equal to its rated value. So Armature circuit resistance method is usually referred to as a

Constant Torque[𝑘ⱷ𝐼 𝑎] drive method.

Series motor speed control by varying the armature resistance

(a) Schematic circuit diagram and (b) Speed torque](https://image.slidesharecdn.com/praveenkumar-171218064309/85/Speed-Control-Of-DC-Motor-11-320.jpg)

![(a) Schematic diagram of Ward-Leonard

system of speed control

(b) Torque-speed and Power-speed

characteristics of Ward-Leonard system

Speeds from the lowest possible speed up to base speed are obtained by G output

voltage, with constant motor field flux. Since the speed control is carried out with

rated current 𝐼 𝑎 & with constant motor field flux ⱷ, A constant torque[𝑘ⱷ𝐼 𝑎] and

variation of Power[𝑇𝑁] to the speed is obtained. Thus Constant Torque & Variable

Power drive is obtained up to base speed.](https://image.slidesharecdn.com/praveenkumar-171218064309/85/Speed-Control-Of-DC-Motor-16-320.jpg)

![ [1]. Electrical Machinery By Dr. P.S. Bimbhra

[2]. Electrical Machines By Ashfaq Husain

[3] Electric Machinery Fundamentals By Stephen J. Chapman](https://image.slidesharecdn.com/praveenkumar-171218064309/85/Speed-Control-Of-DC-Motor-22-320.jpg)