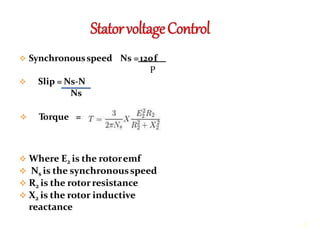

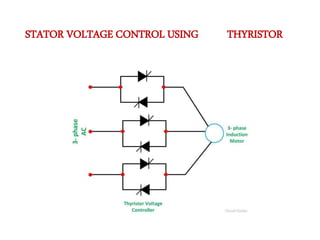

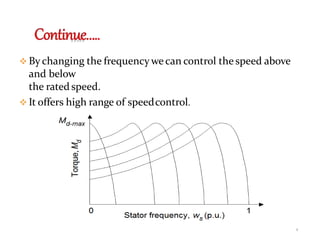

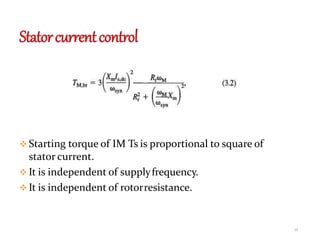

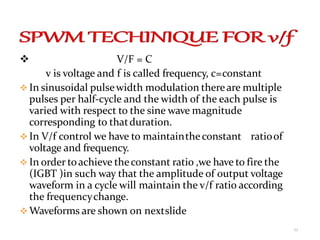

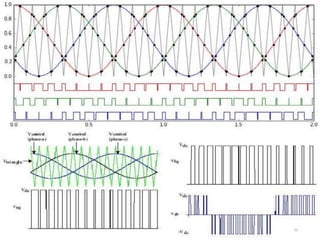

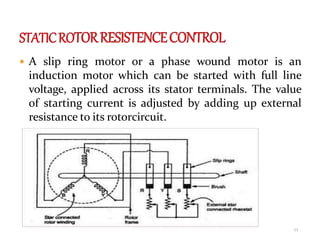

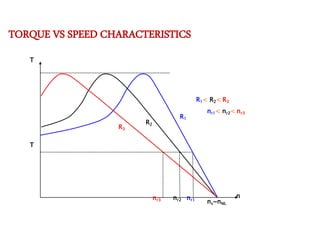

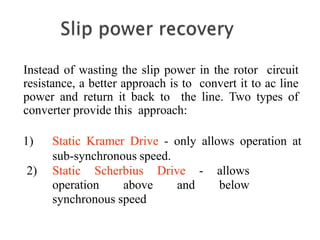

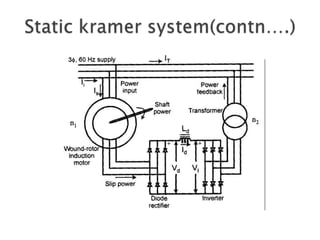

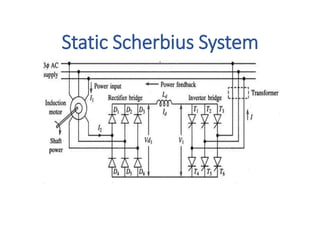

This document discusses speed control methods for three-phase induction motors. It describes various speed control techniques including stator voltage control, stator frequency control, V/F control, and static rotor resistance control. It explains the advantages of speed control, such as energy savings and meeting different process requirements. Industrial applications of induction motor drives are also mentioned, such as in fans, compressors, pumps and machine tools.