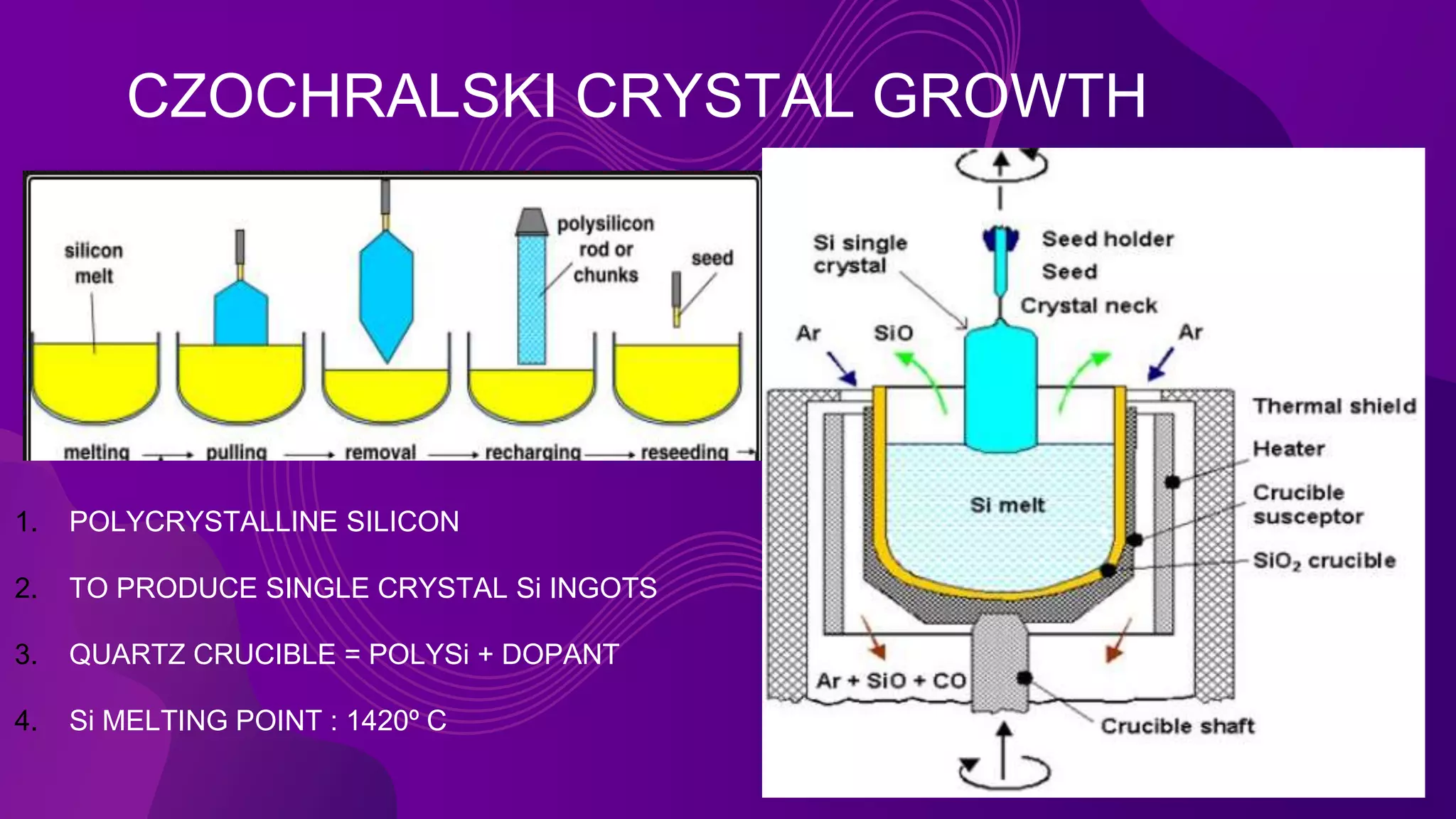

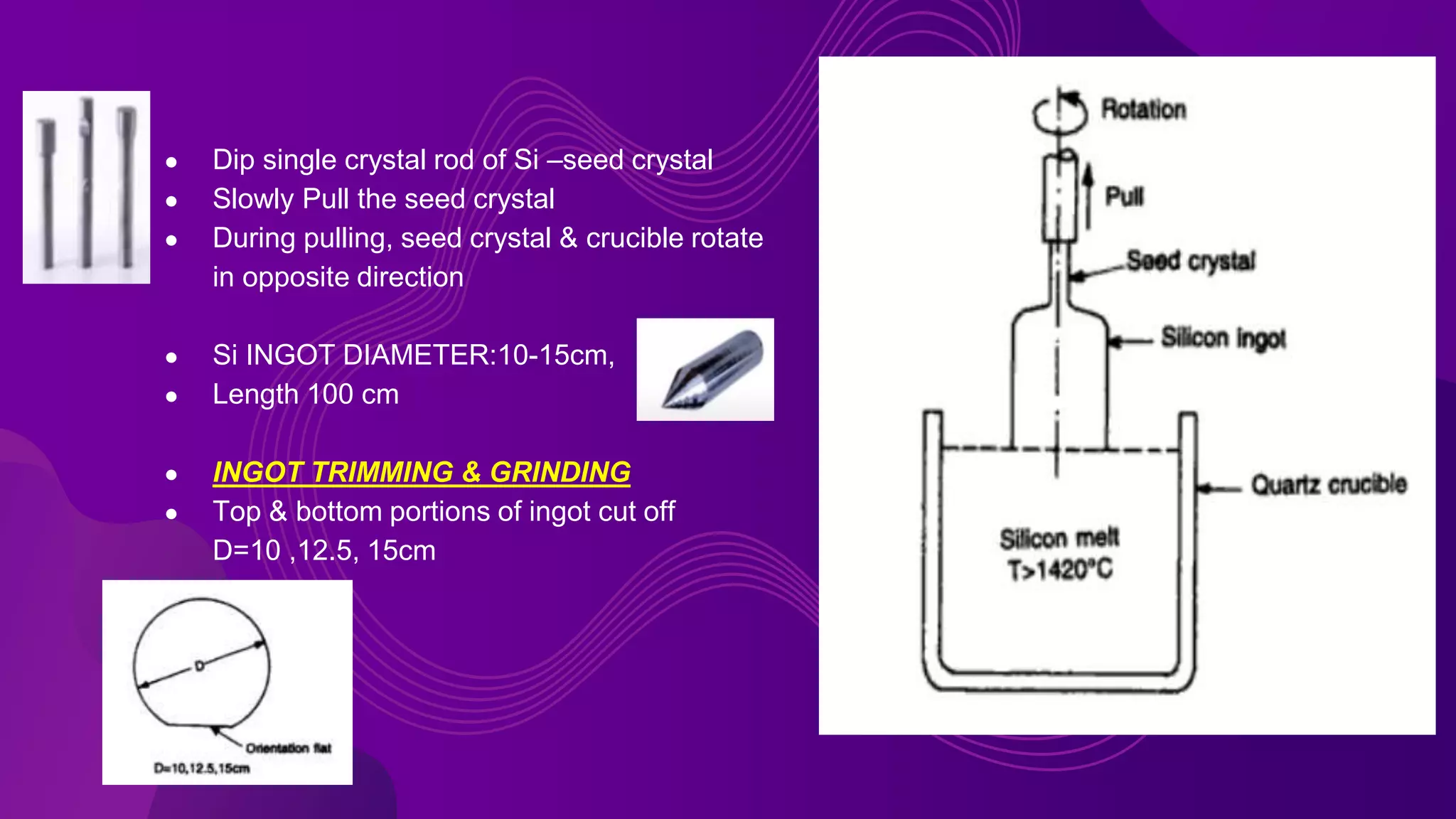

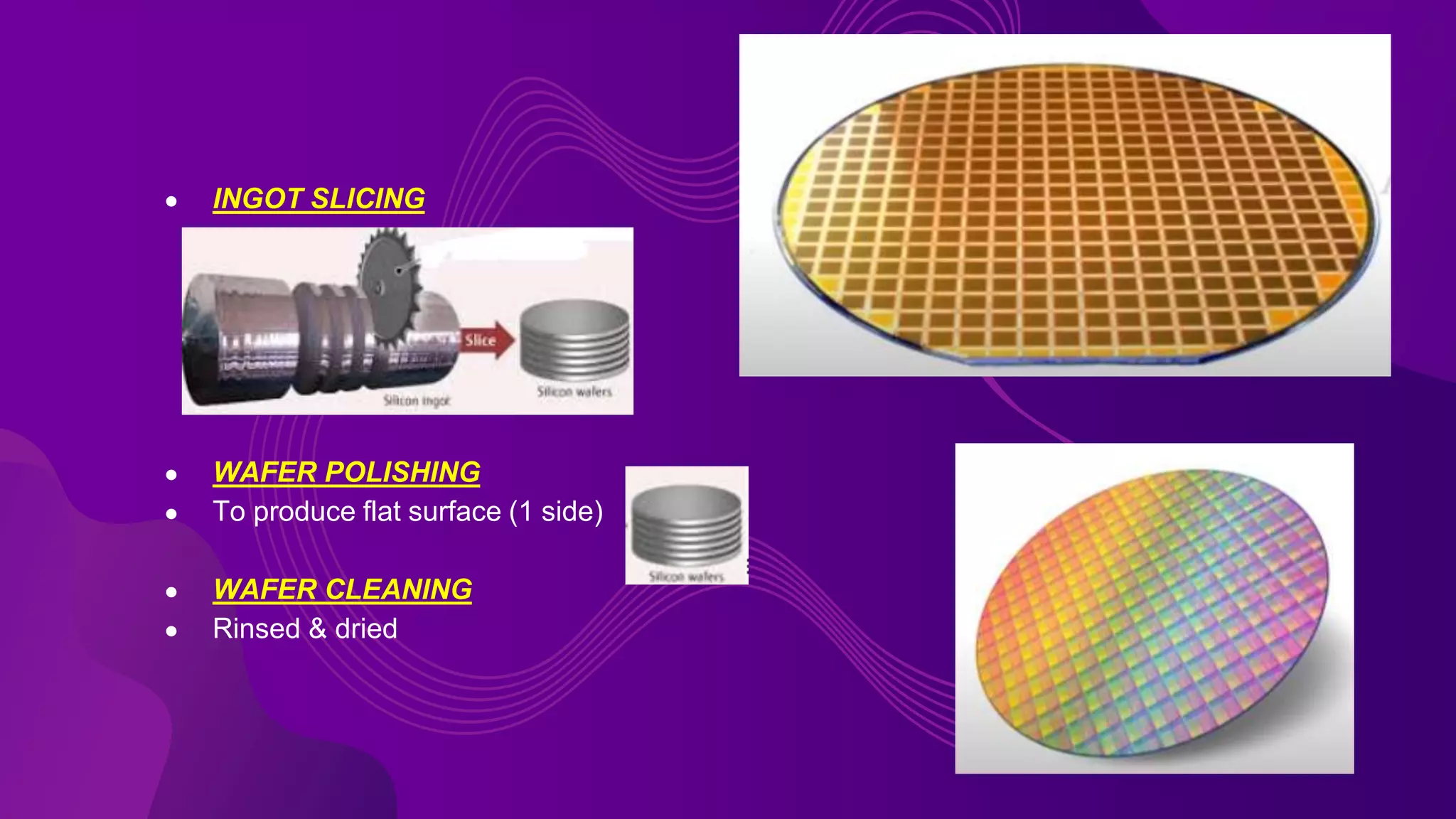

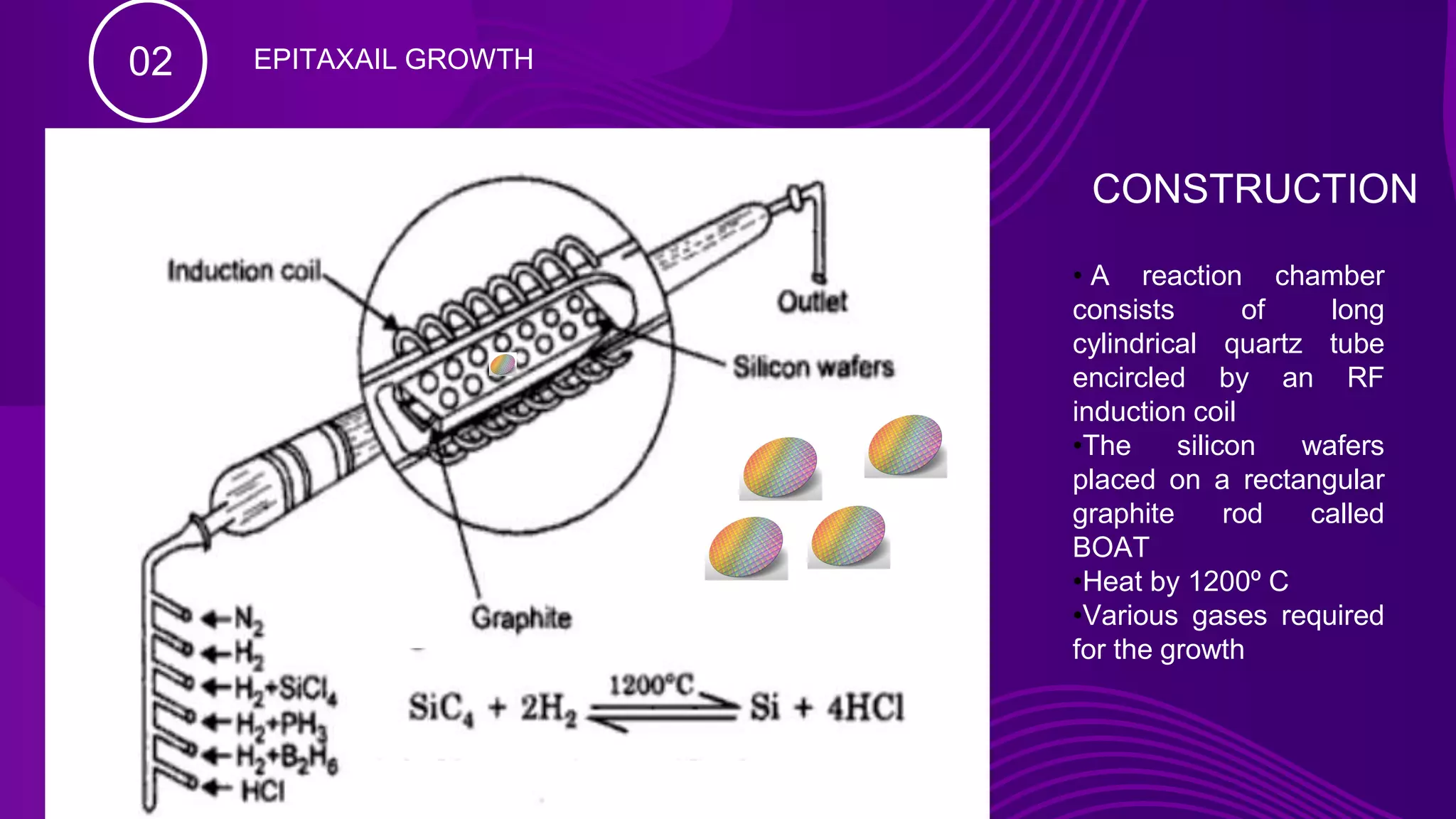

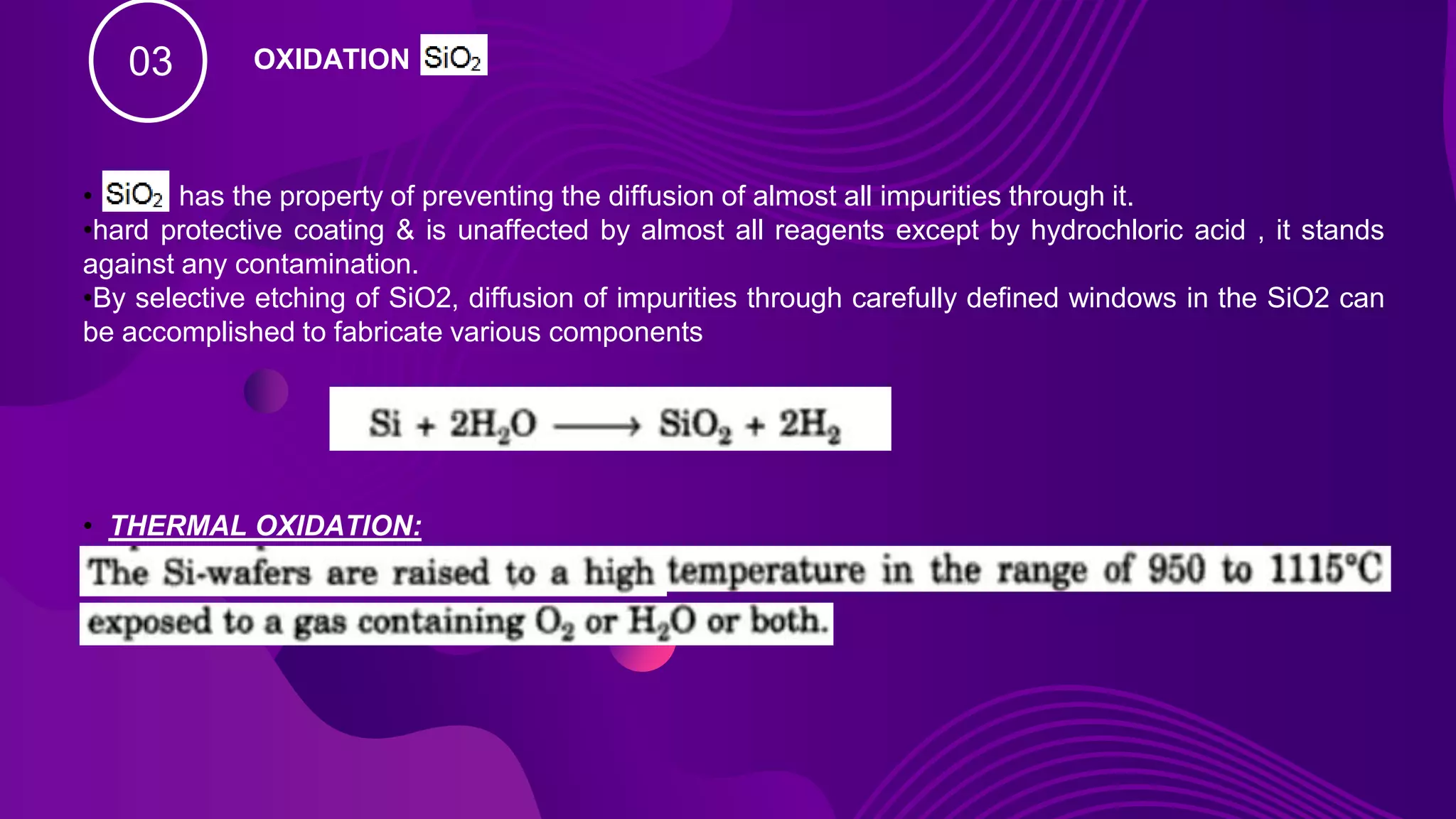

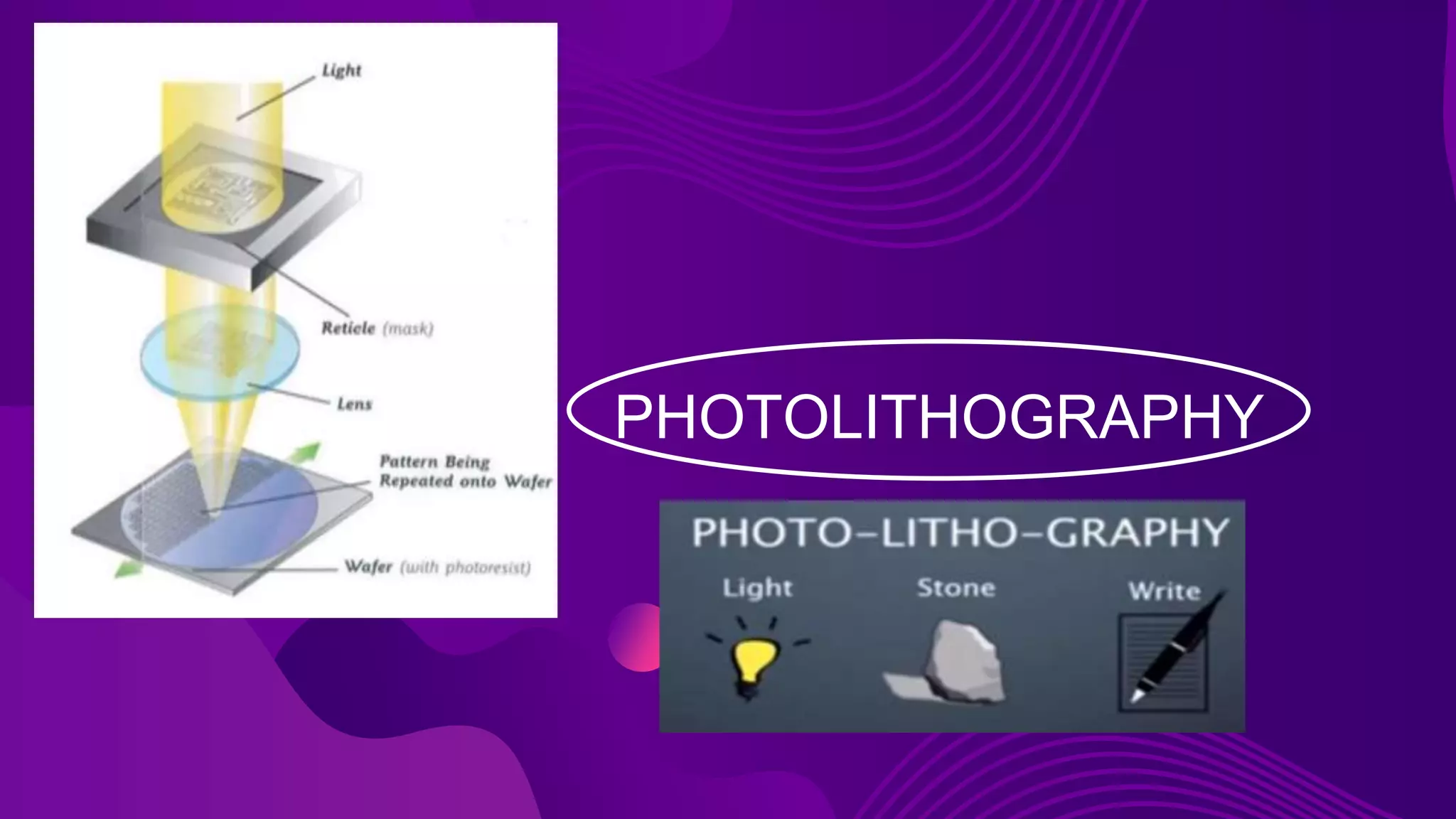

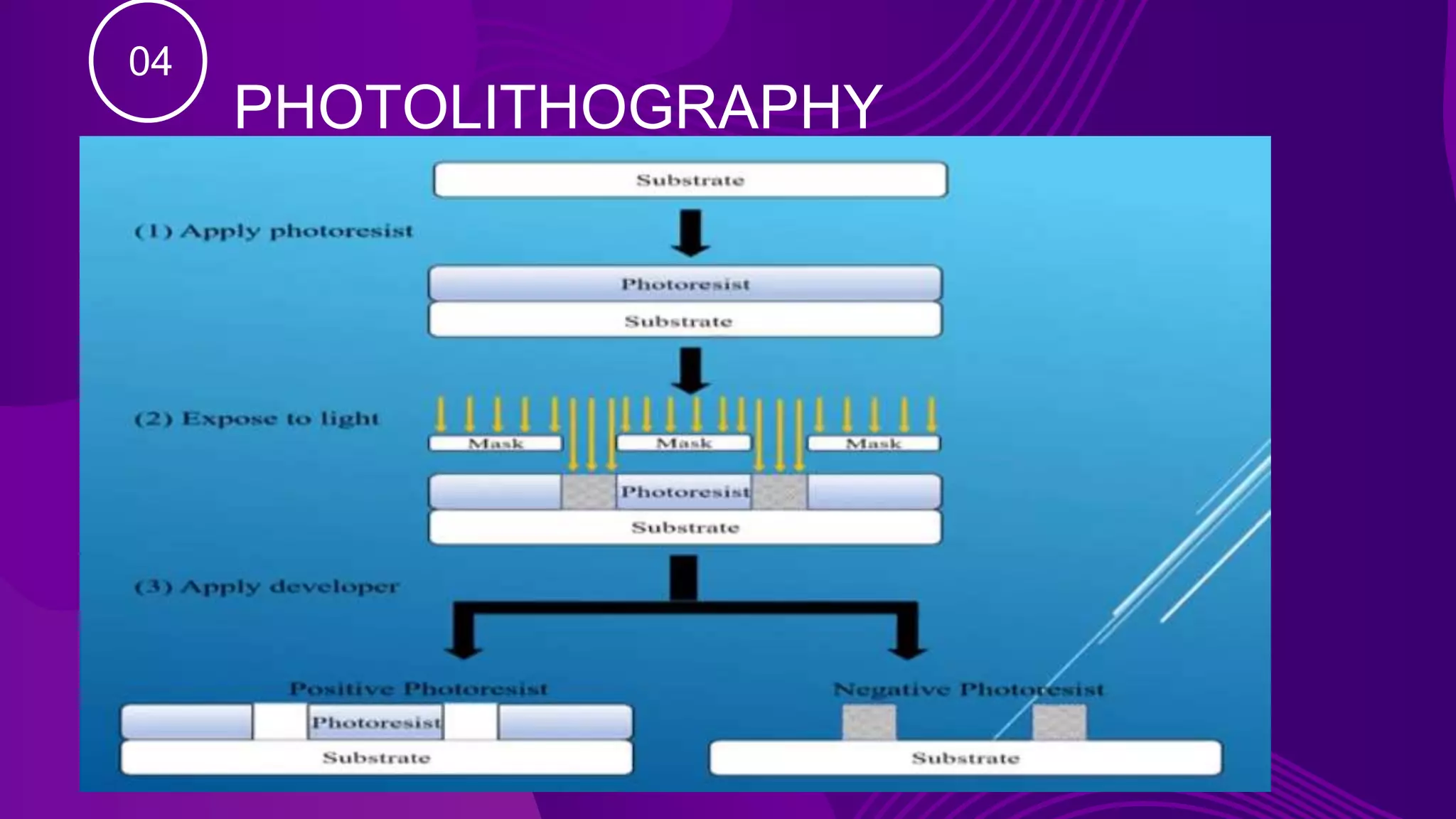

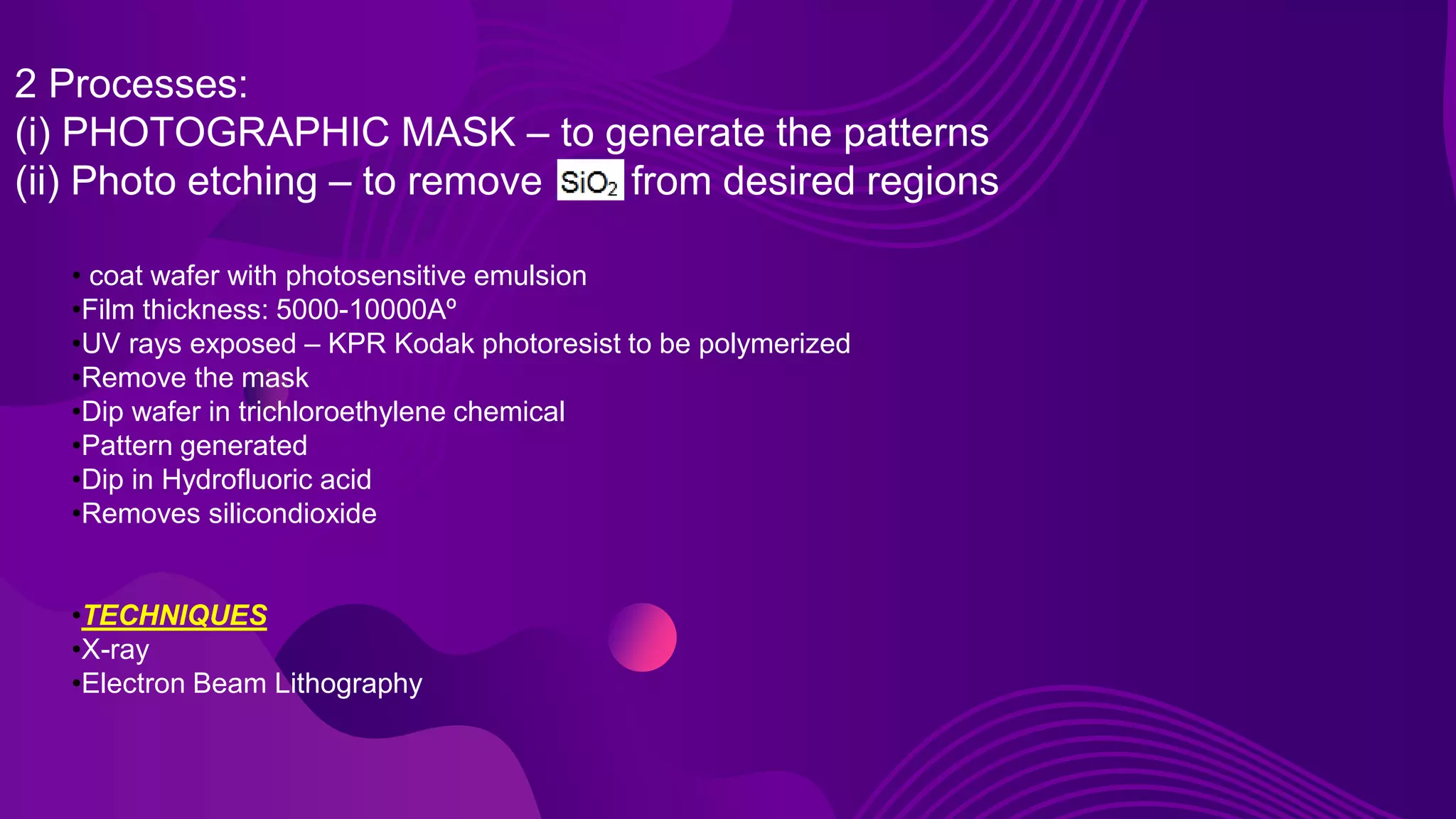

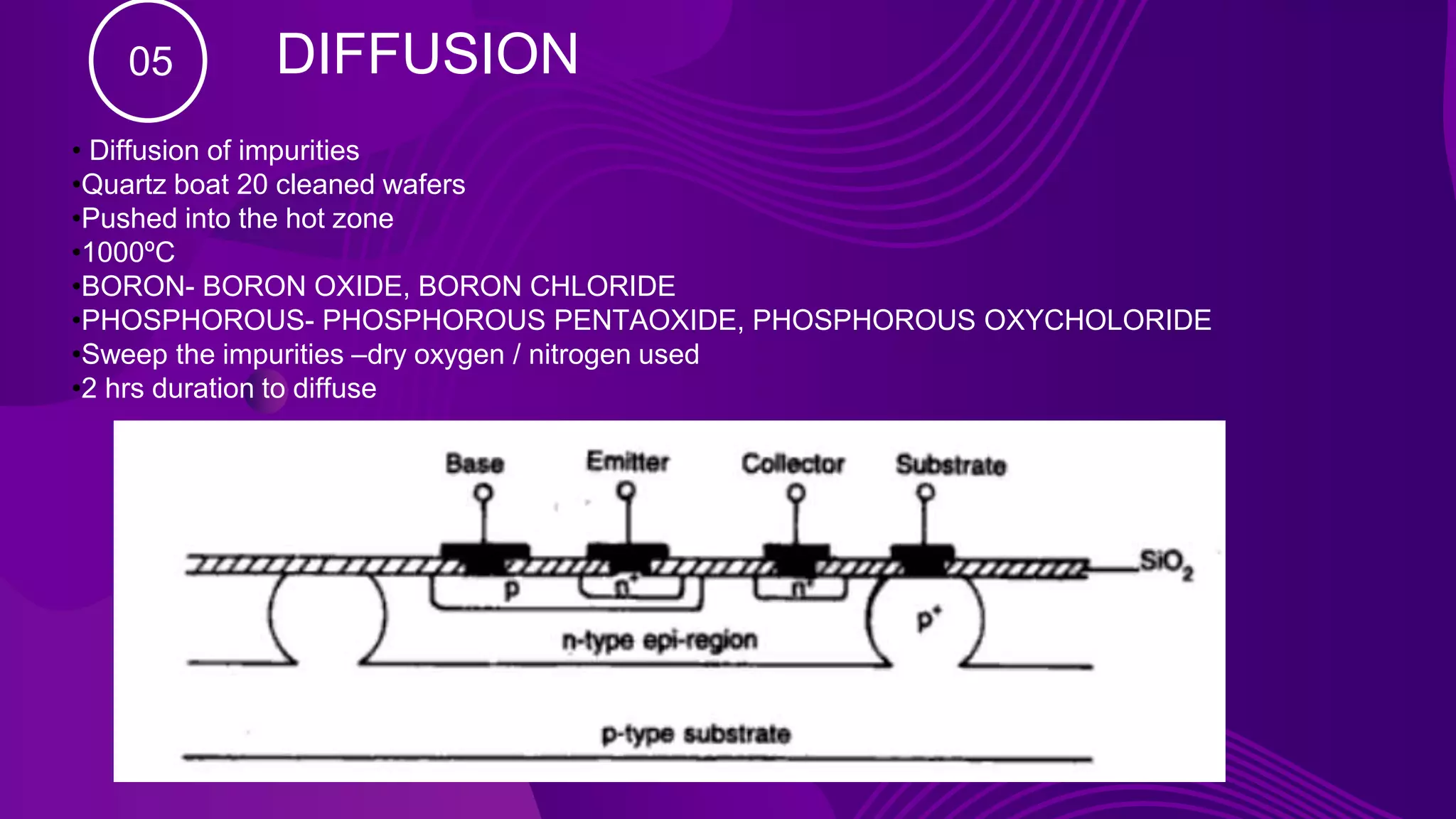

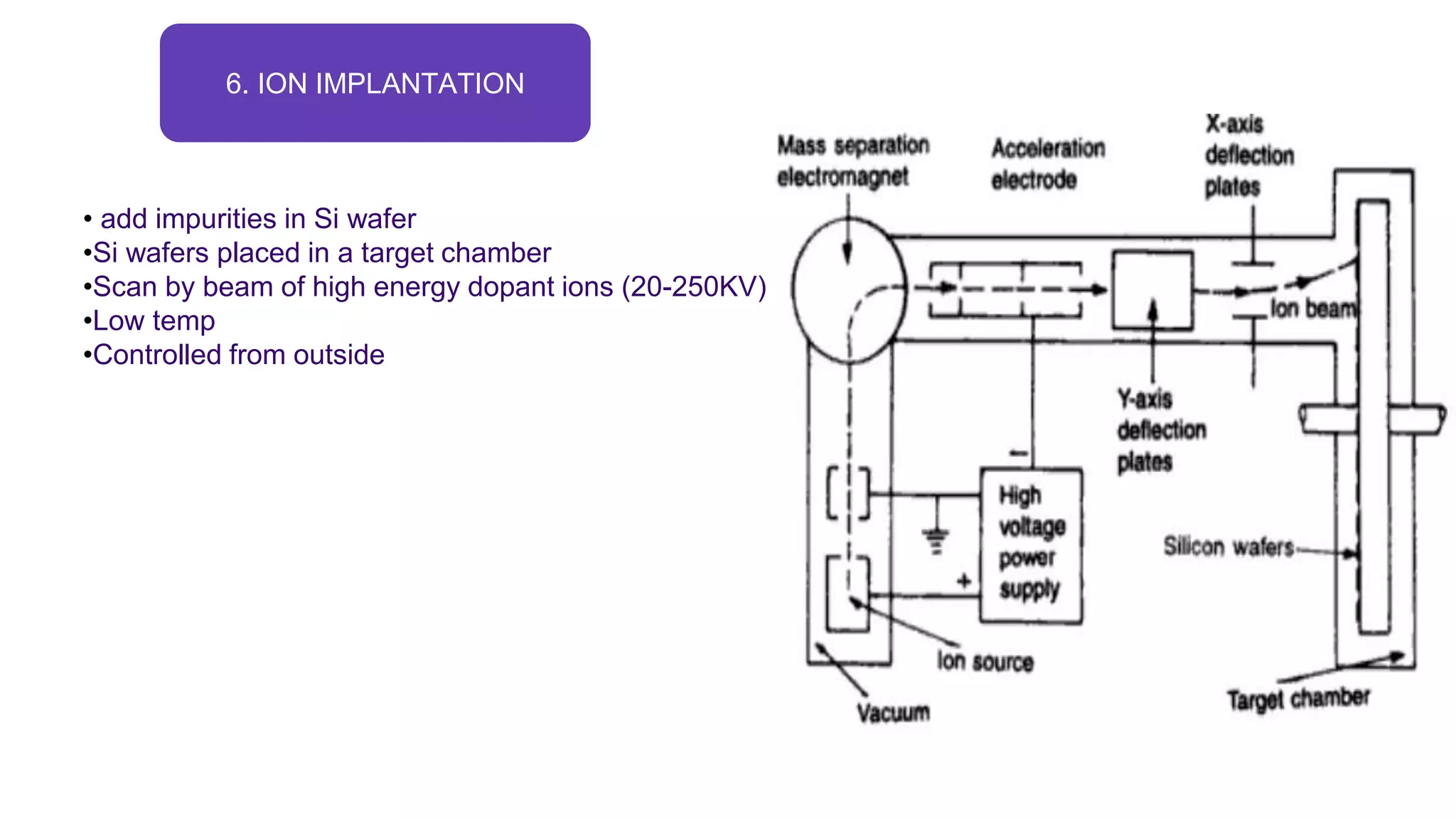

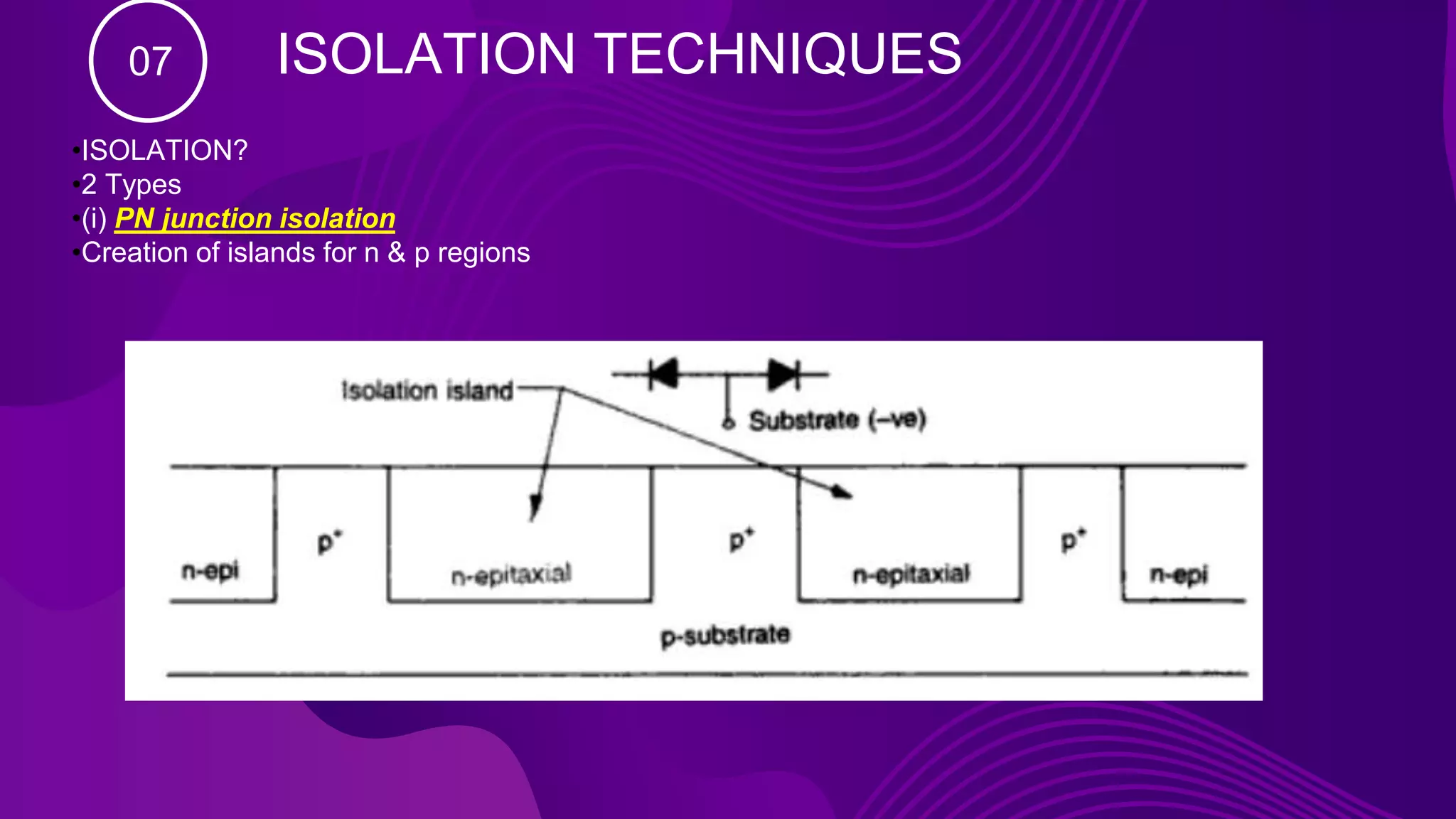

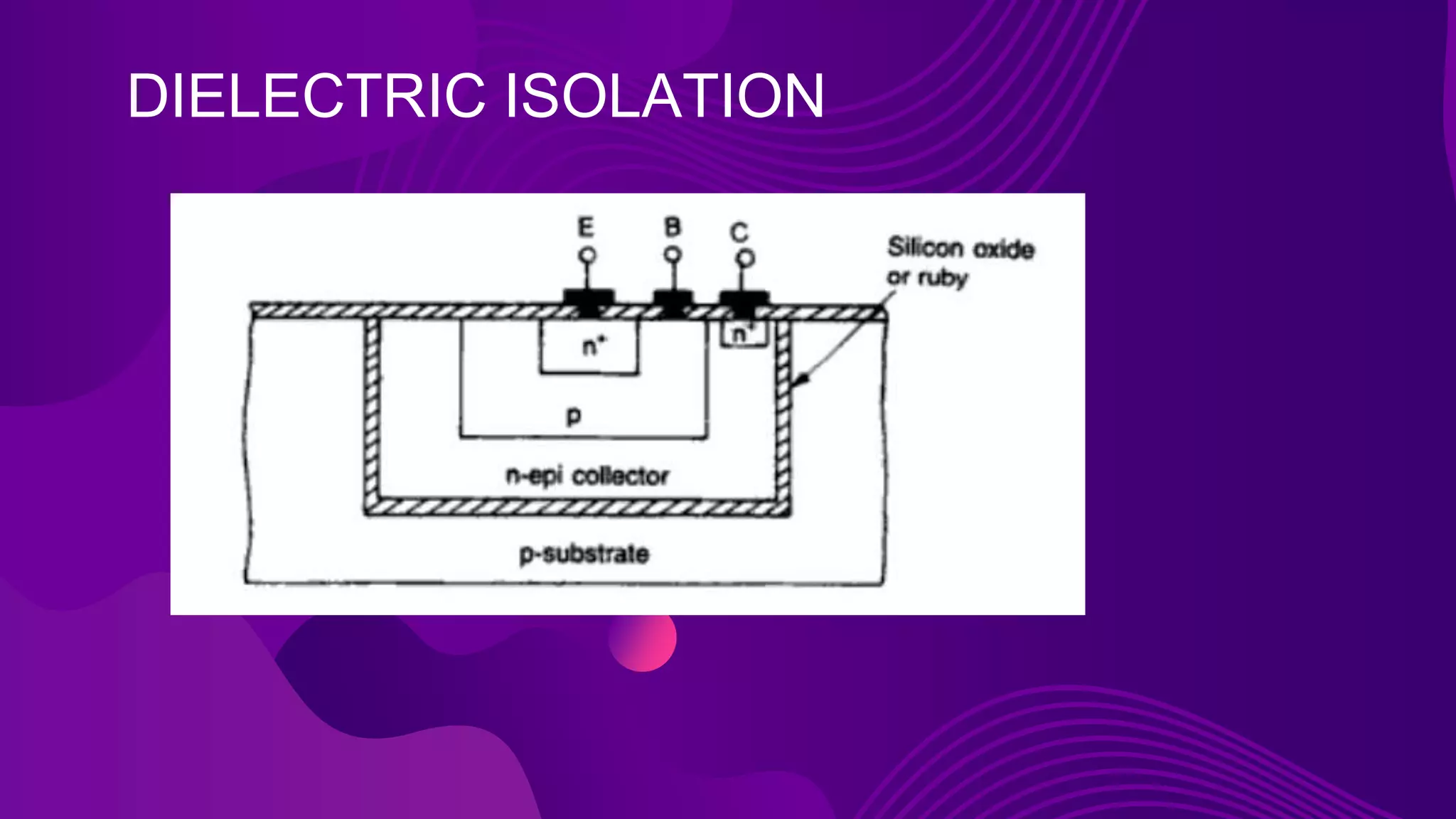

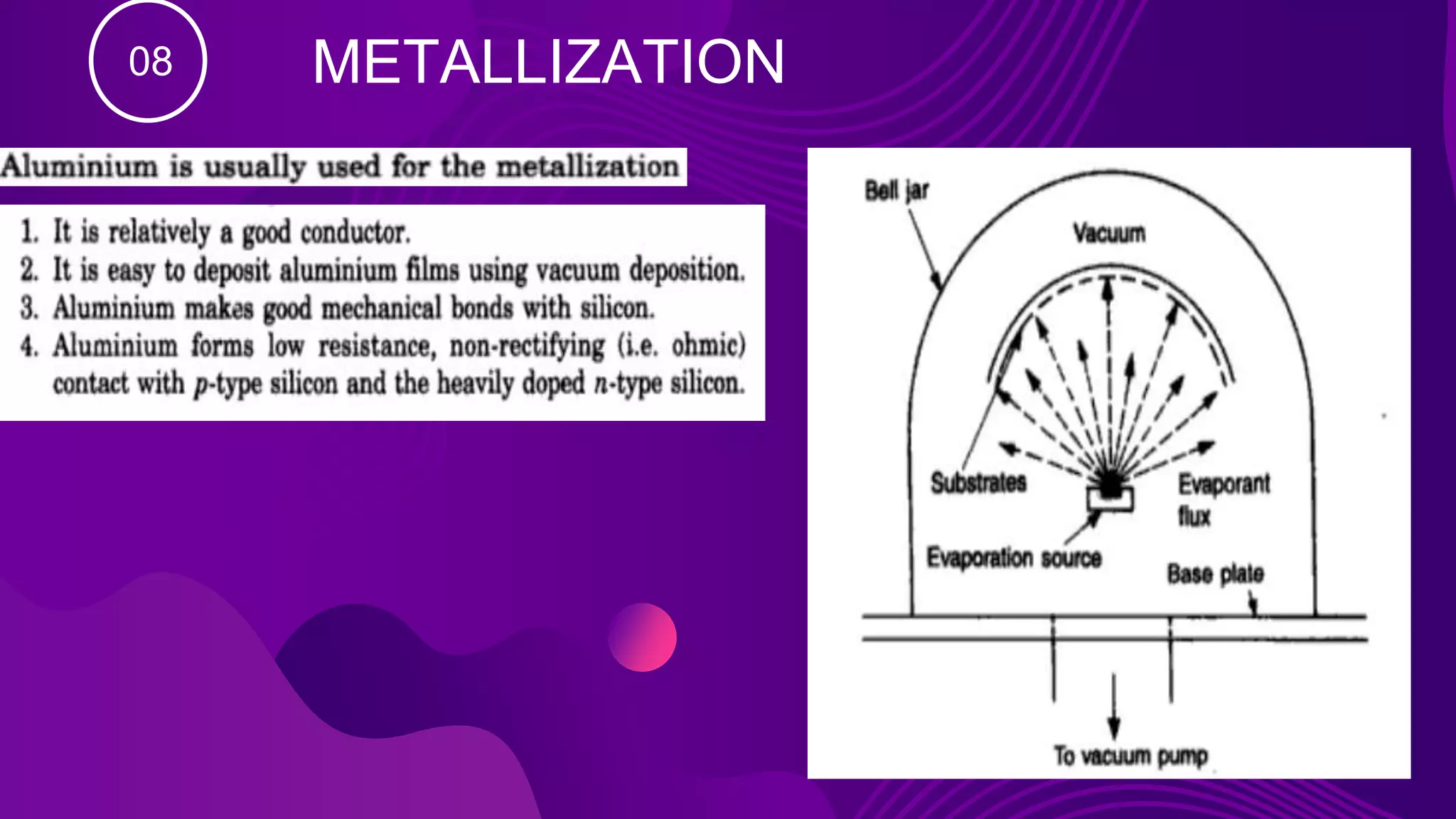

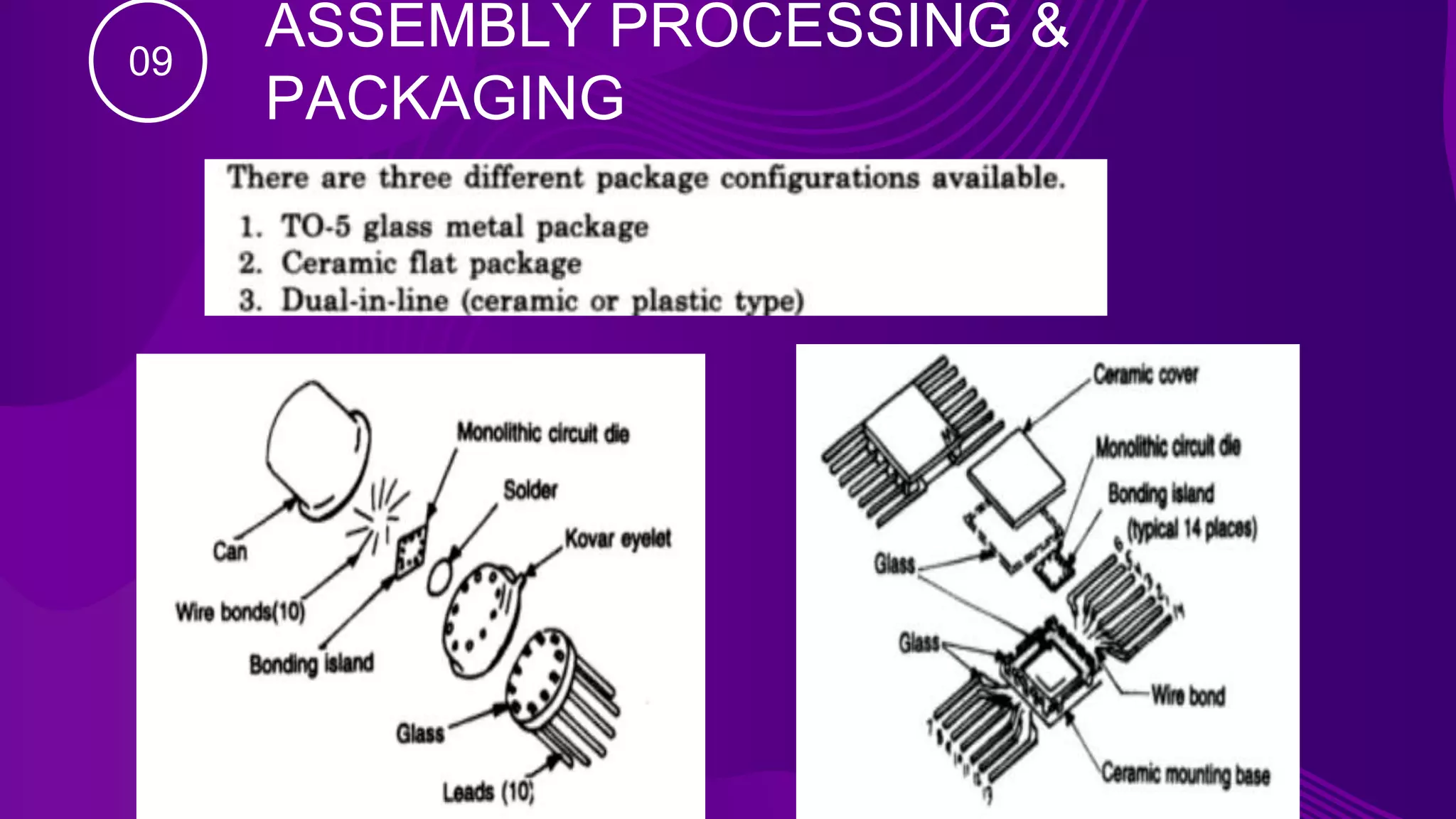

The document discusses the basic processes involved in the fabrication of monolithic integrated circuits. It describes the key steps which include silicon wafer preparation using the Czochralski crystal growth technique, epitaxial growth, oxidation, photolithography, diffusion, ion implantation, isolation techniques, metallization, and assembly/packaging. The overall goal is to introduce various impurities into a silicon wafer in precise locations and patterns to create the different components of an integrated circuit such as transistors, resistors and interconnects on a single silicon chip.