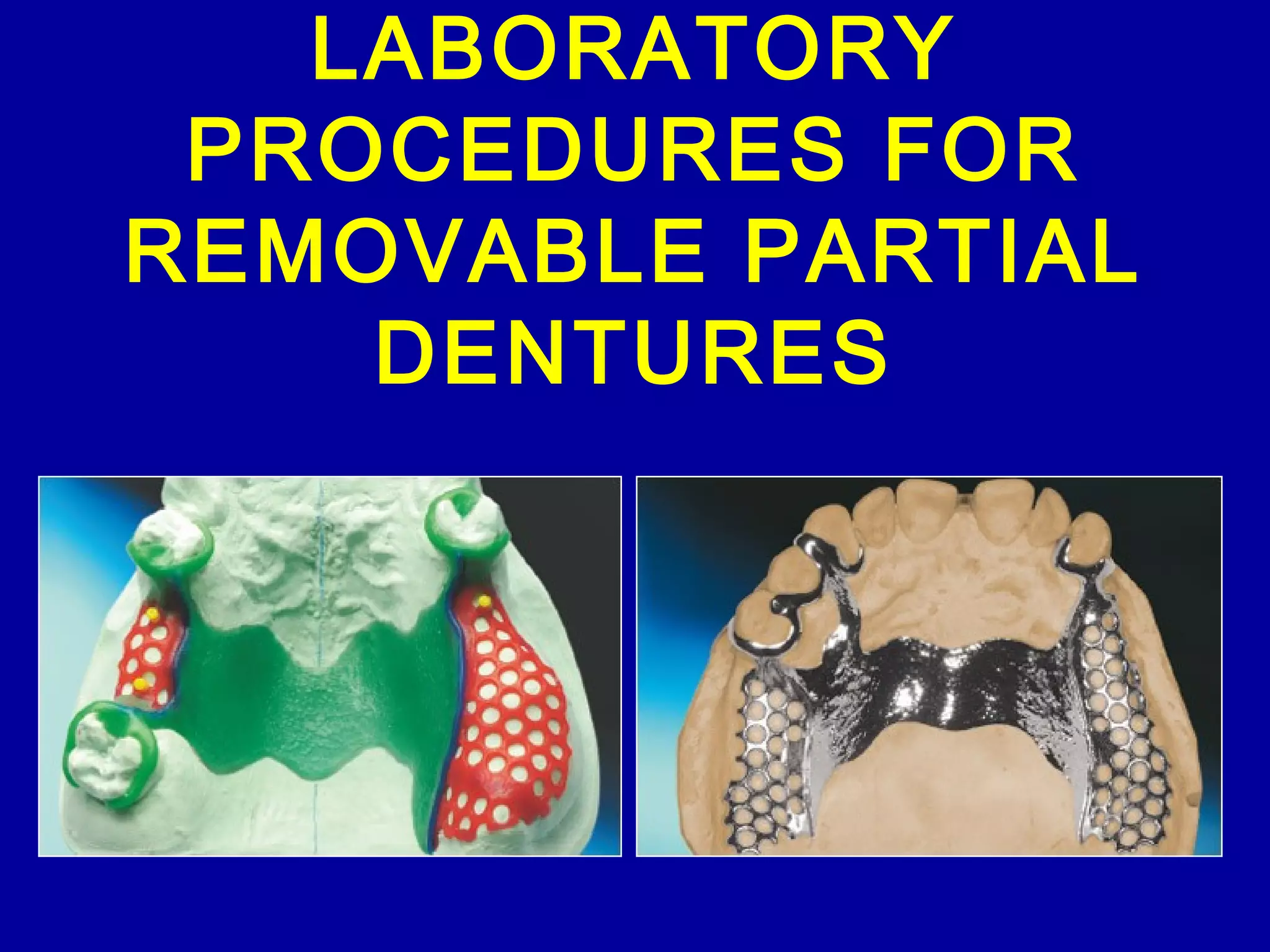

The document describes the key laboratory procedures for fabricating a removable partial denture (RPD) in 8 steps:

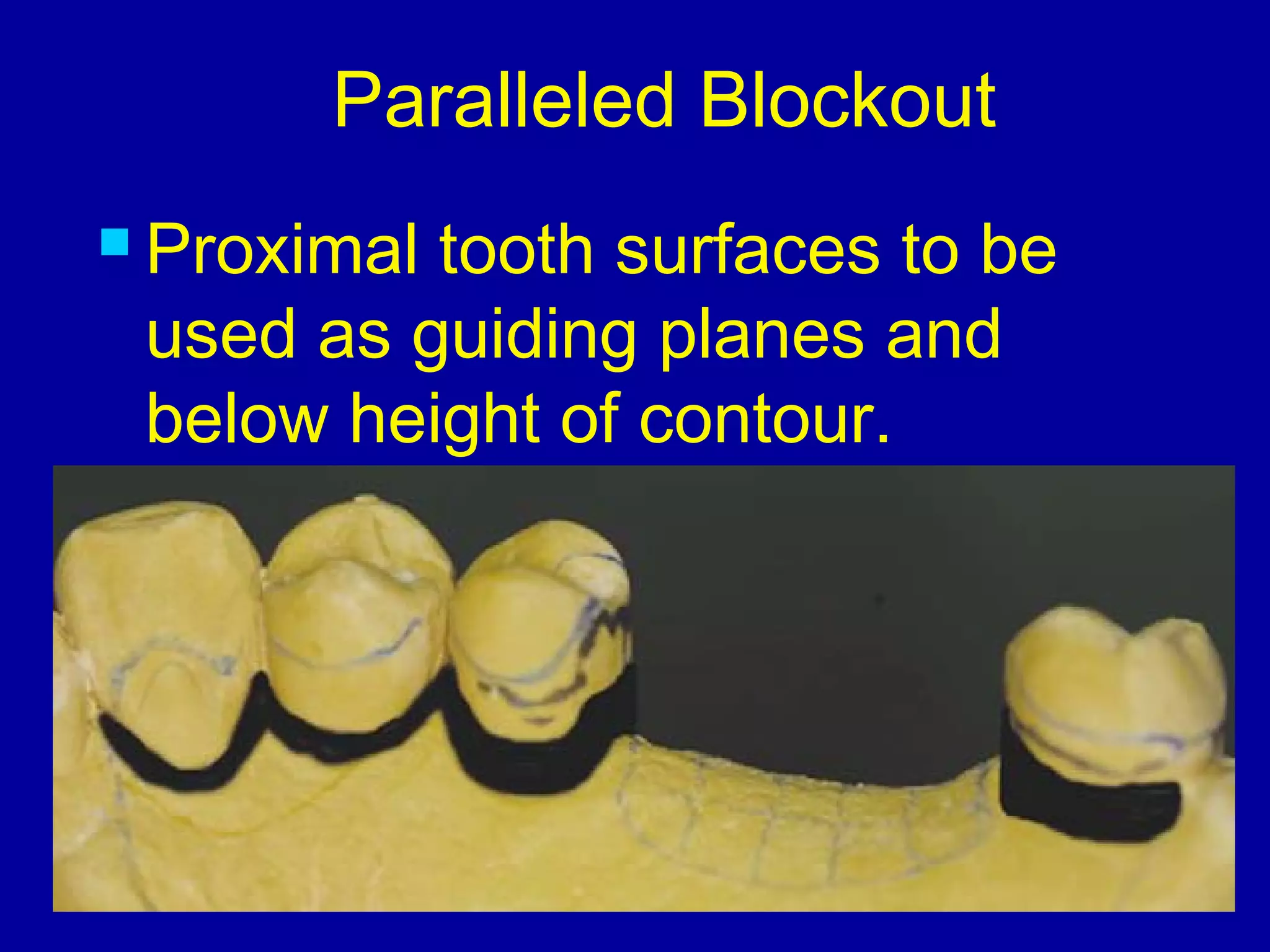

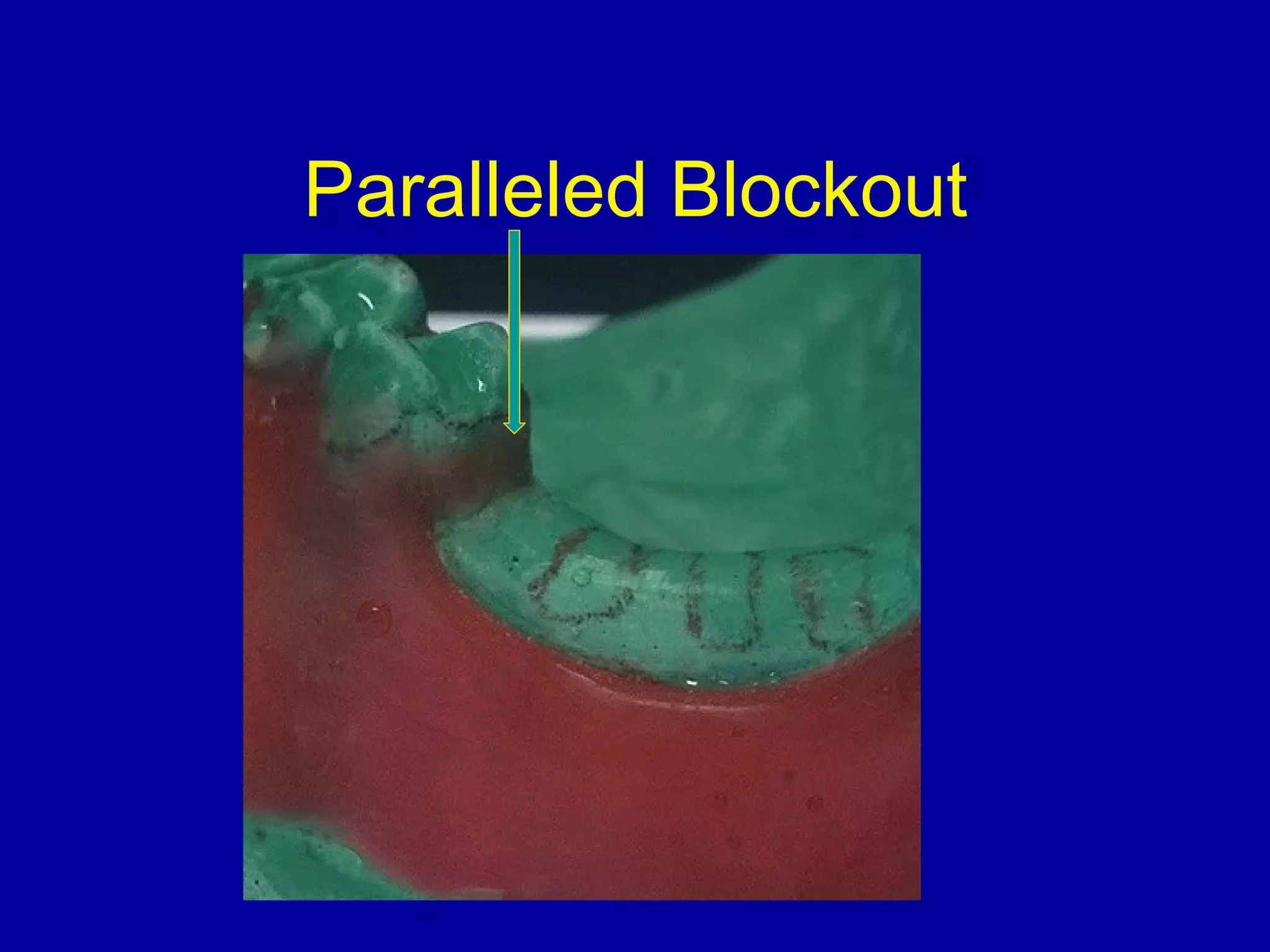

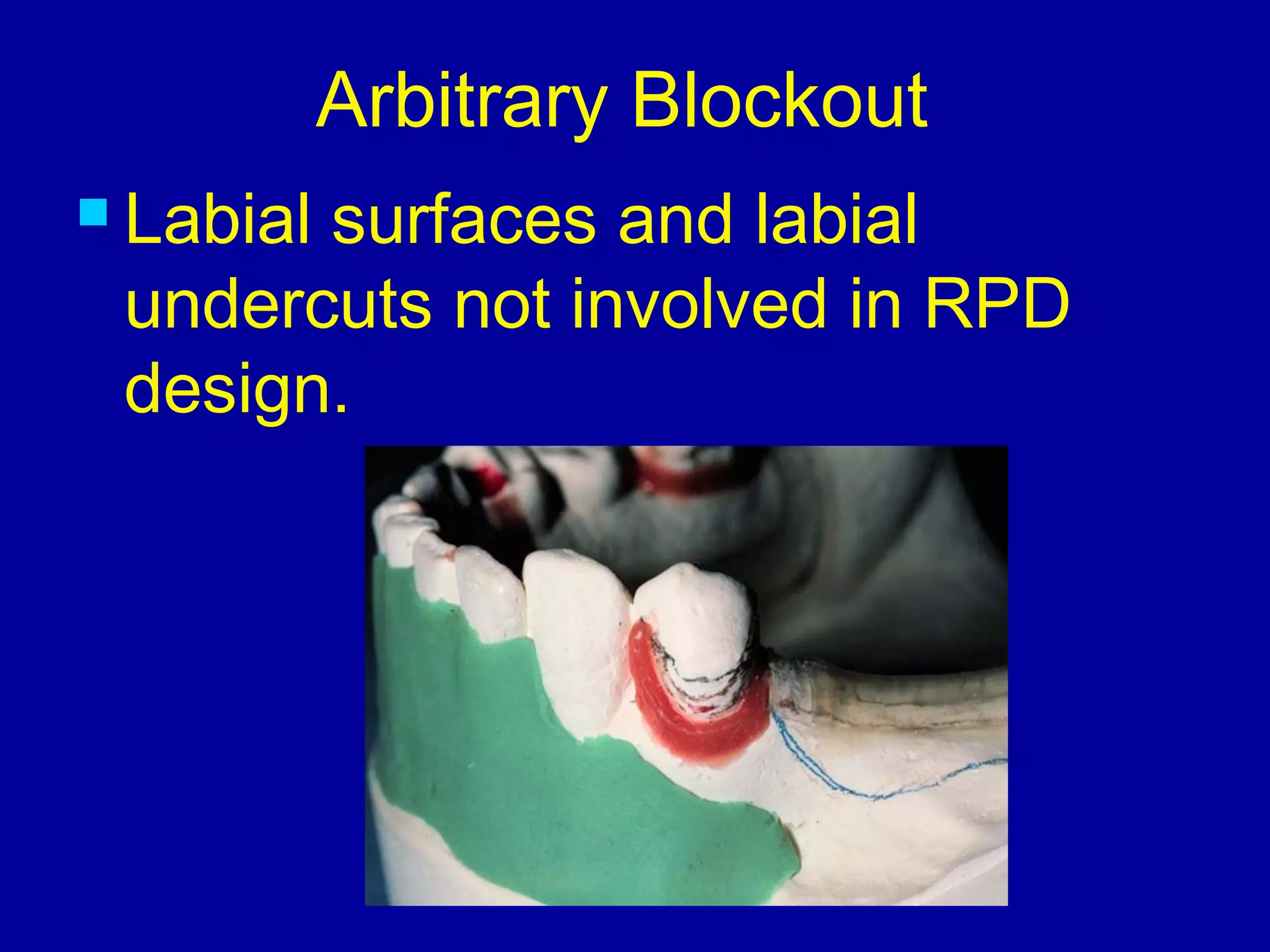

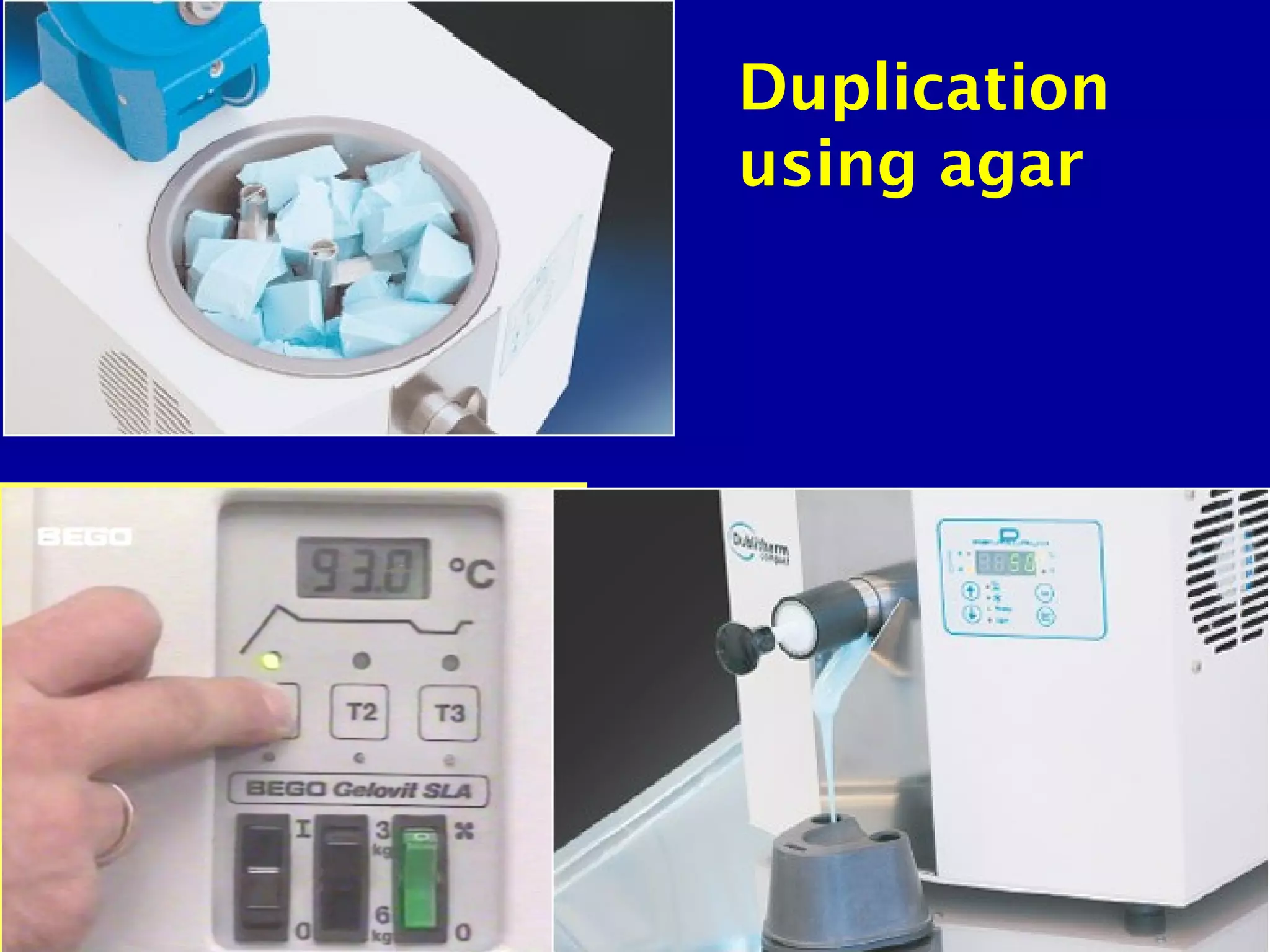

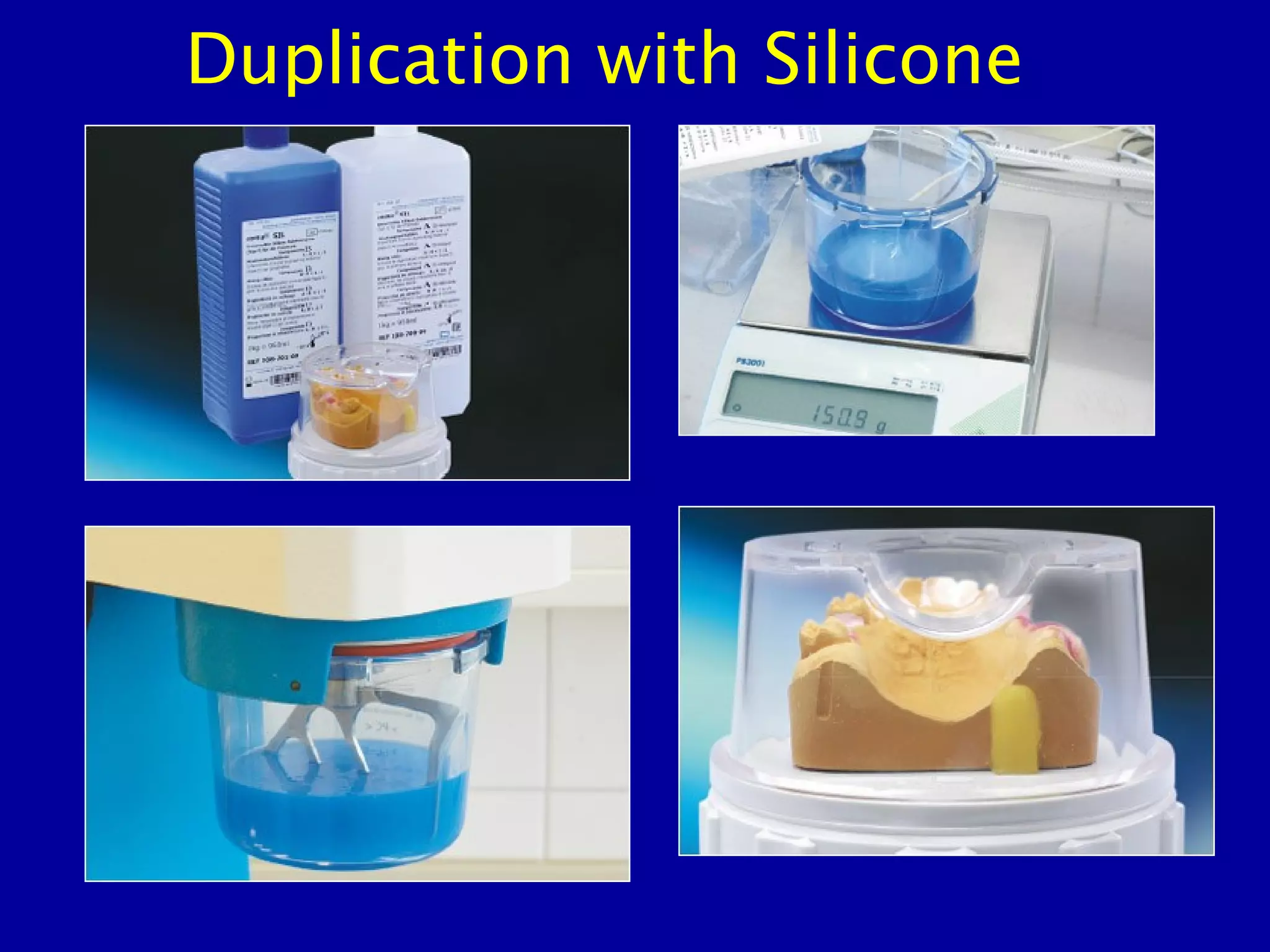

1) Duplicating the stone cast and creating an investment cast

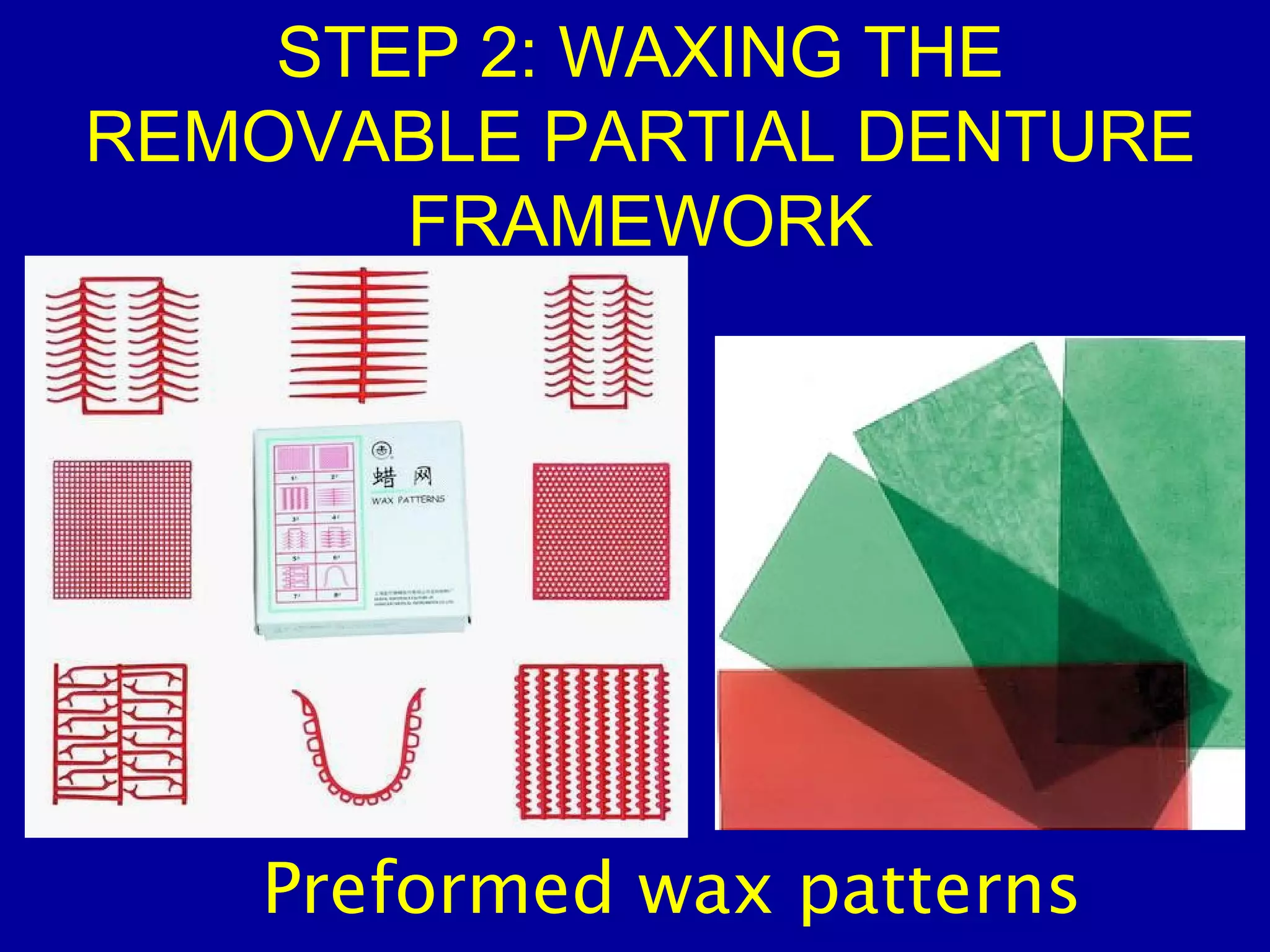

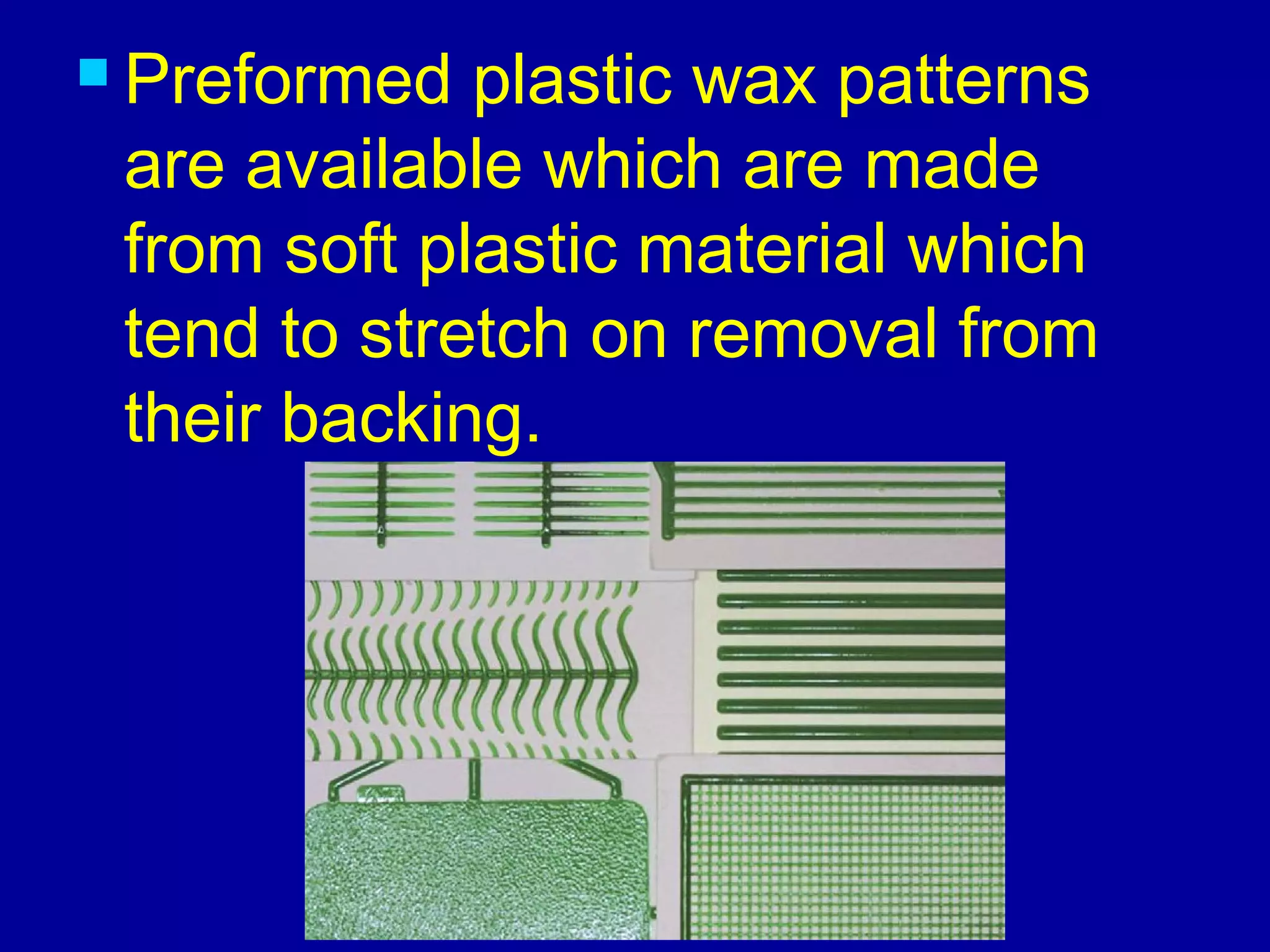

2) Waxing the RPD framework using preformed patterns or wrought wire

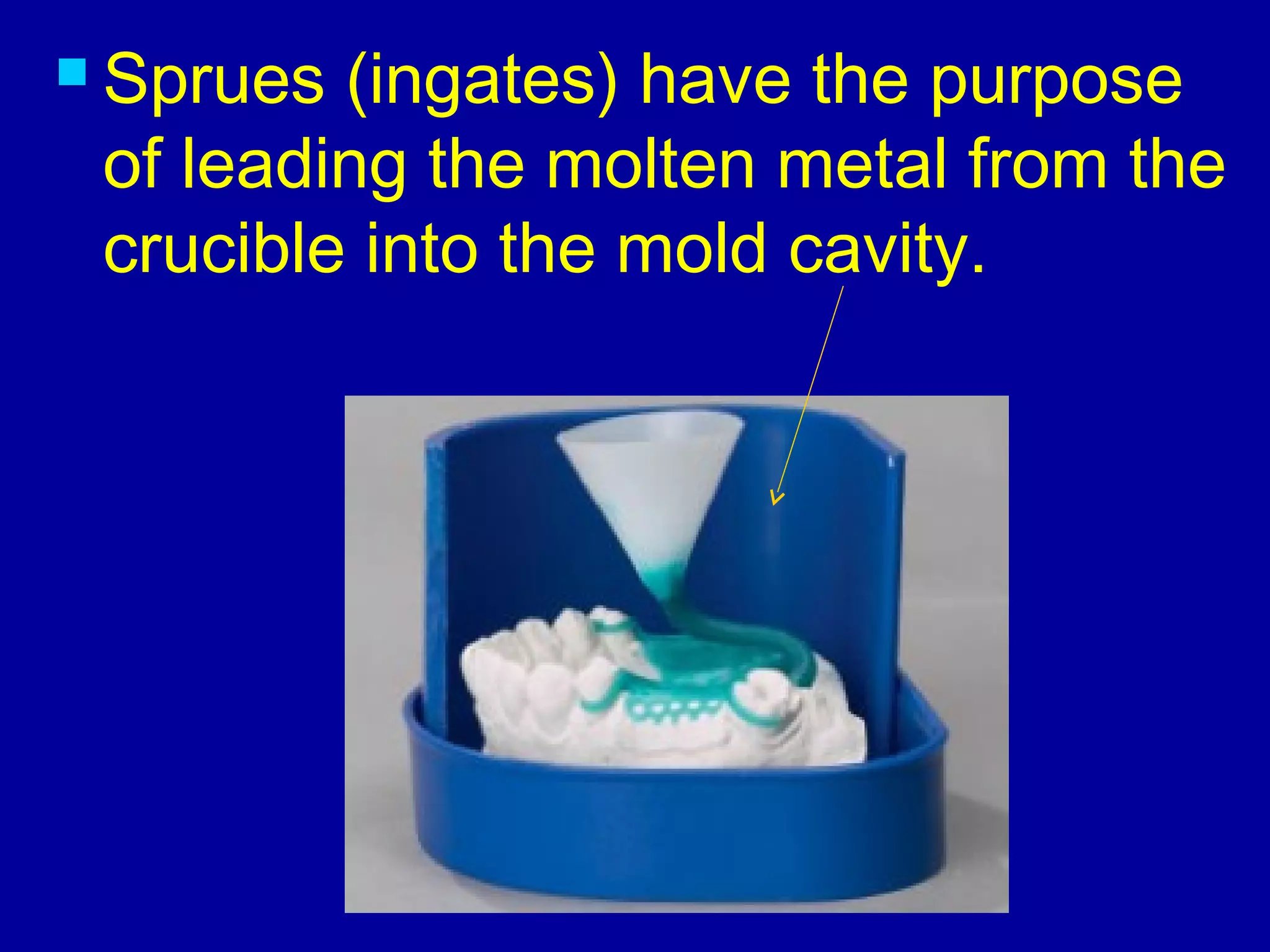

3) Spruing the waxed framework

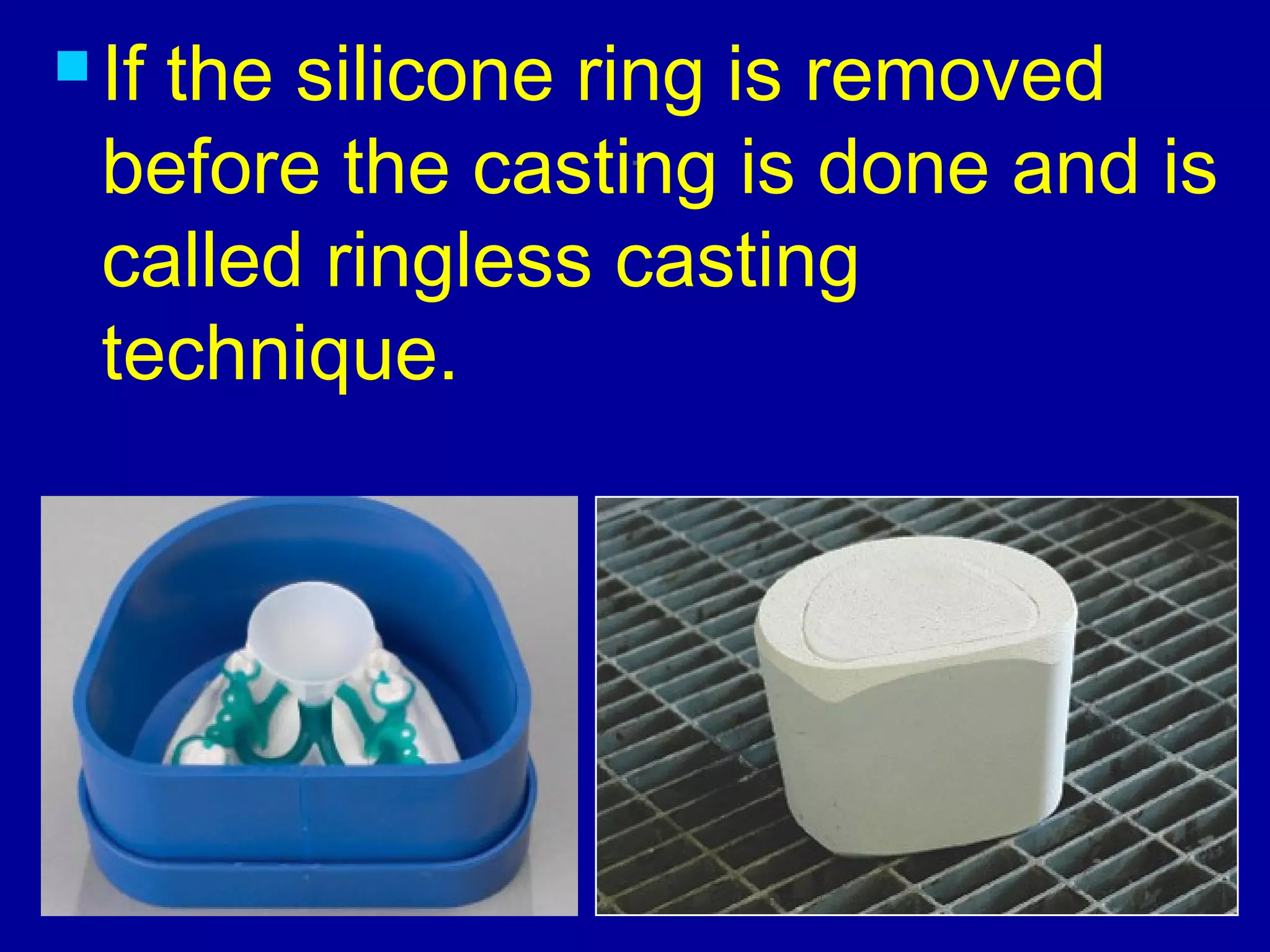

4) Investing and burning out the sprued pattern

5) Casting the framework in metal using centrifugal force

6) Removing the casting from the investment

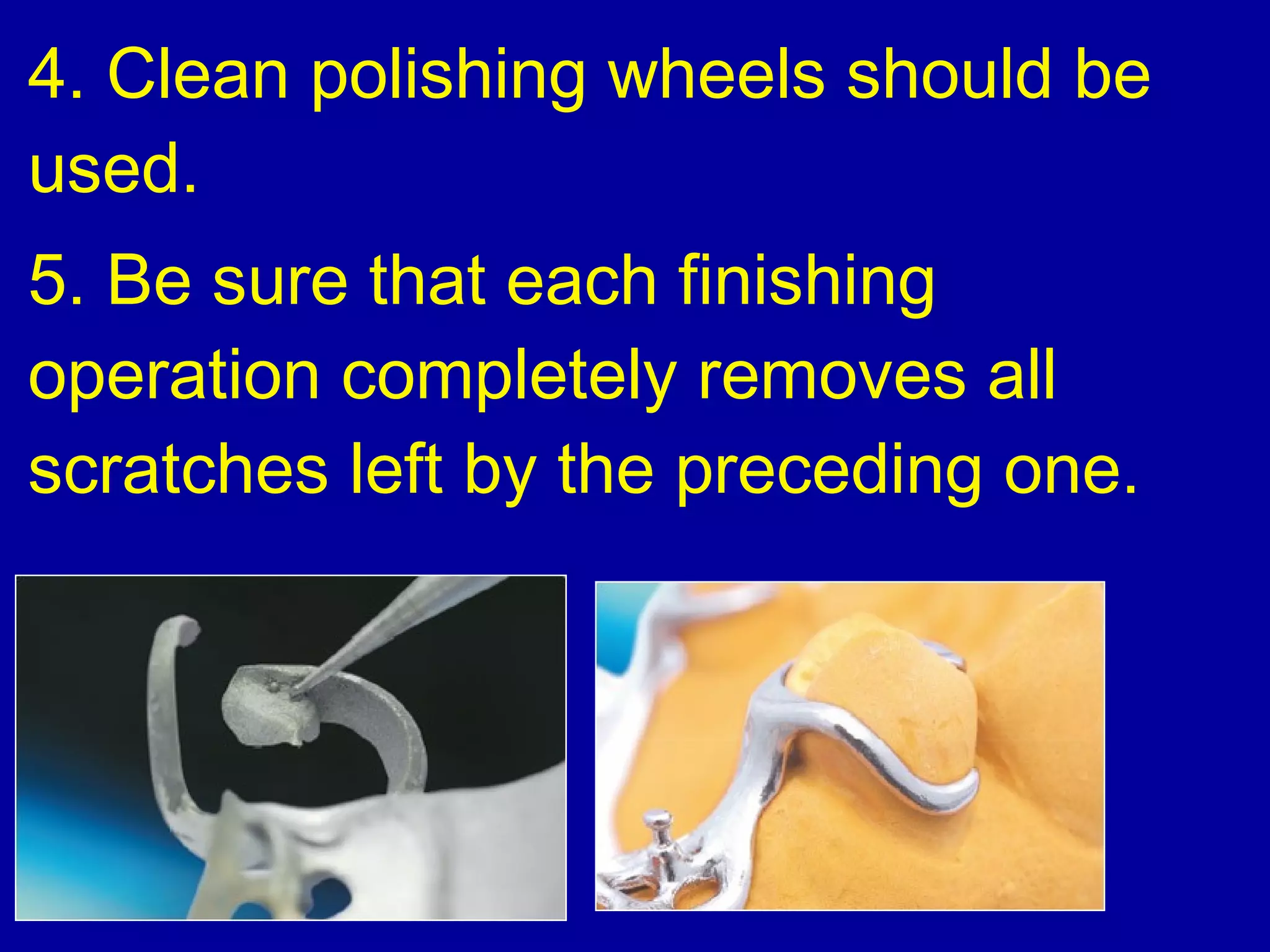

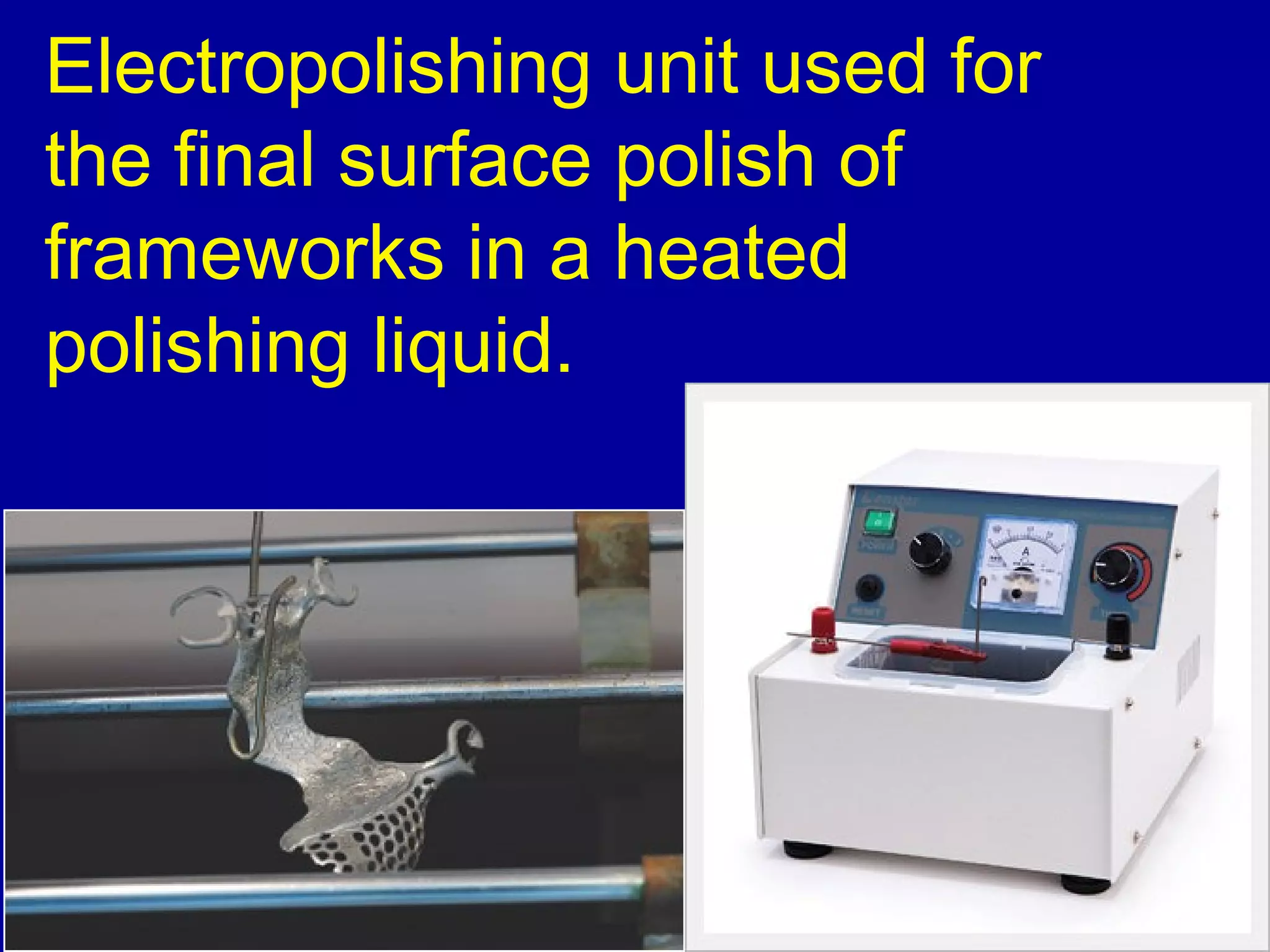

7) Finishing and polishing the framework, including electropolishing

8) Trying in the framework on the patient

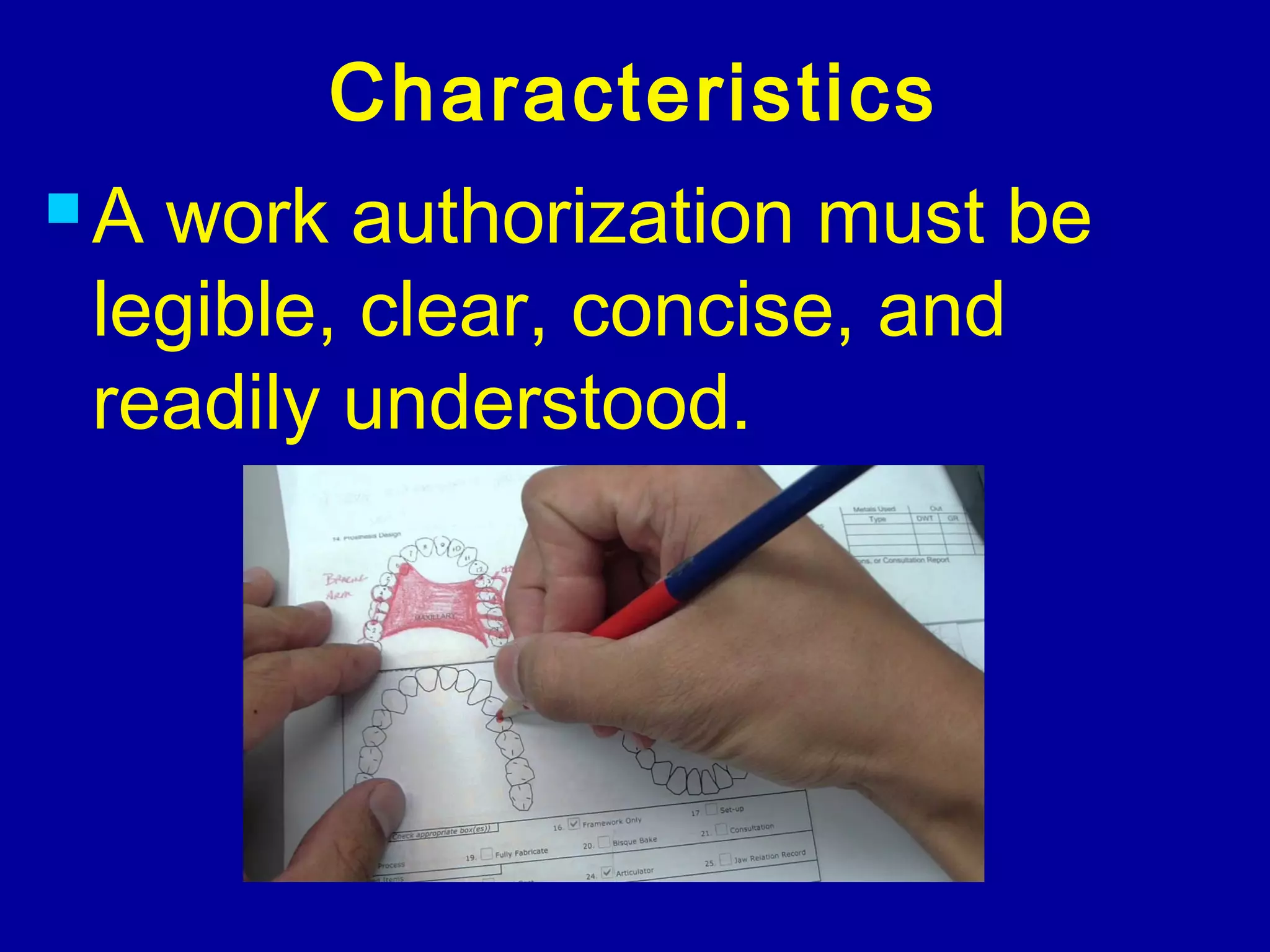

It also explains that a work authorization delineates responsibilities and ensures quality control by providing instructions