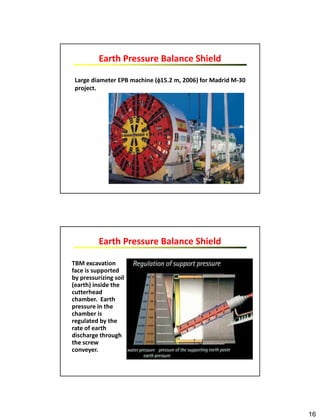

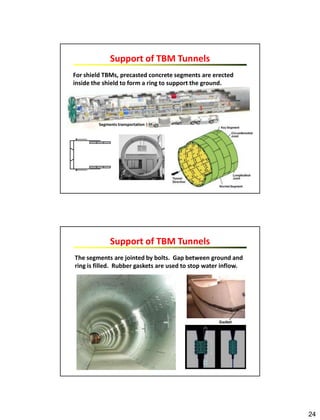

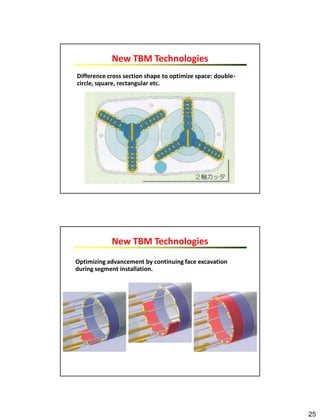

The document provides an overview of tunnel boring machines (TBMs) and their use for mechanized tunnel construction. It discusses various TBM types including gripper TBMs used for hard rock, slurry shields that use pressurized bentonite for ground support, and earth pressure balance machines that regulate soil pressure to support the tunnel face. The advantages and limitations of each type are presented for different ground conditions. Images and diagrams are included to illustrate the components and functions of the various TBMs.