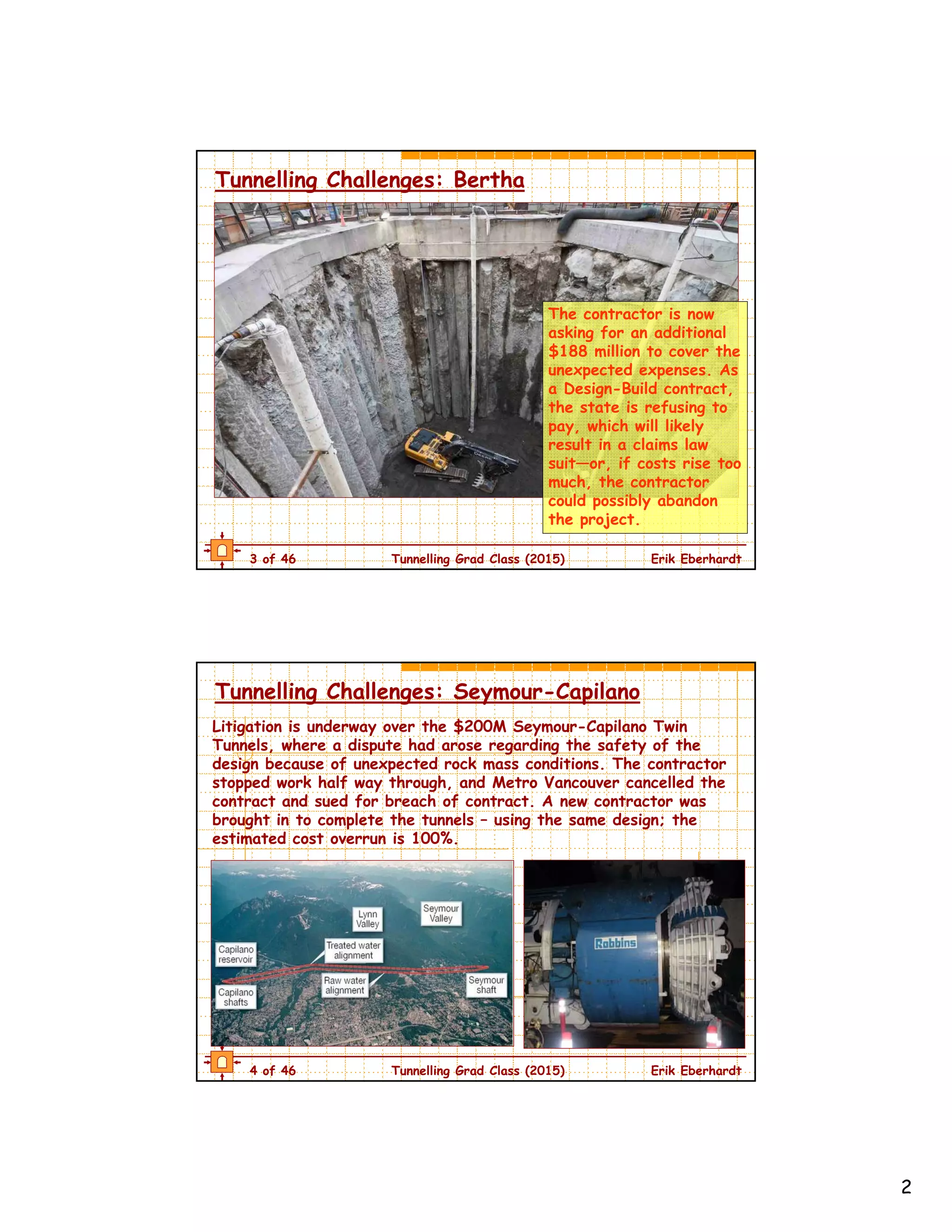

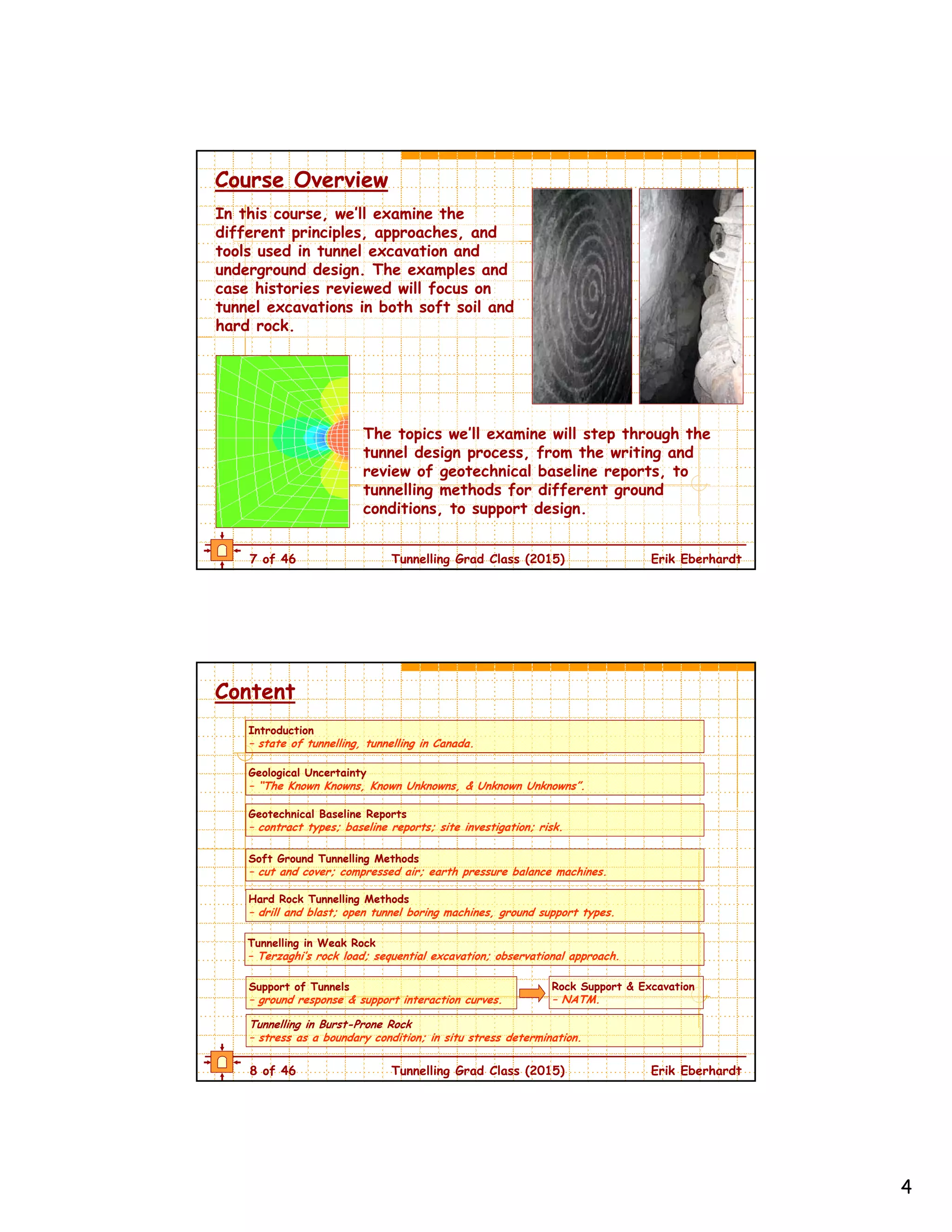

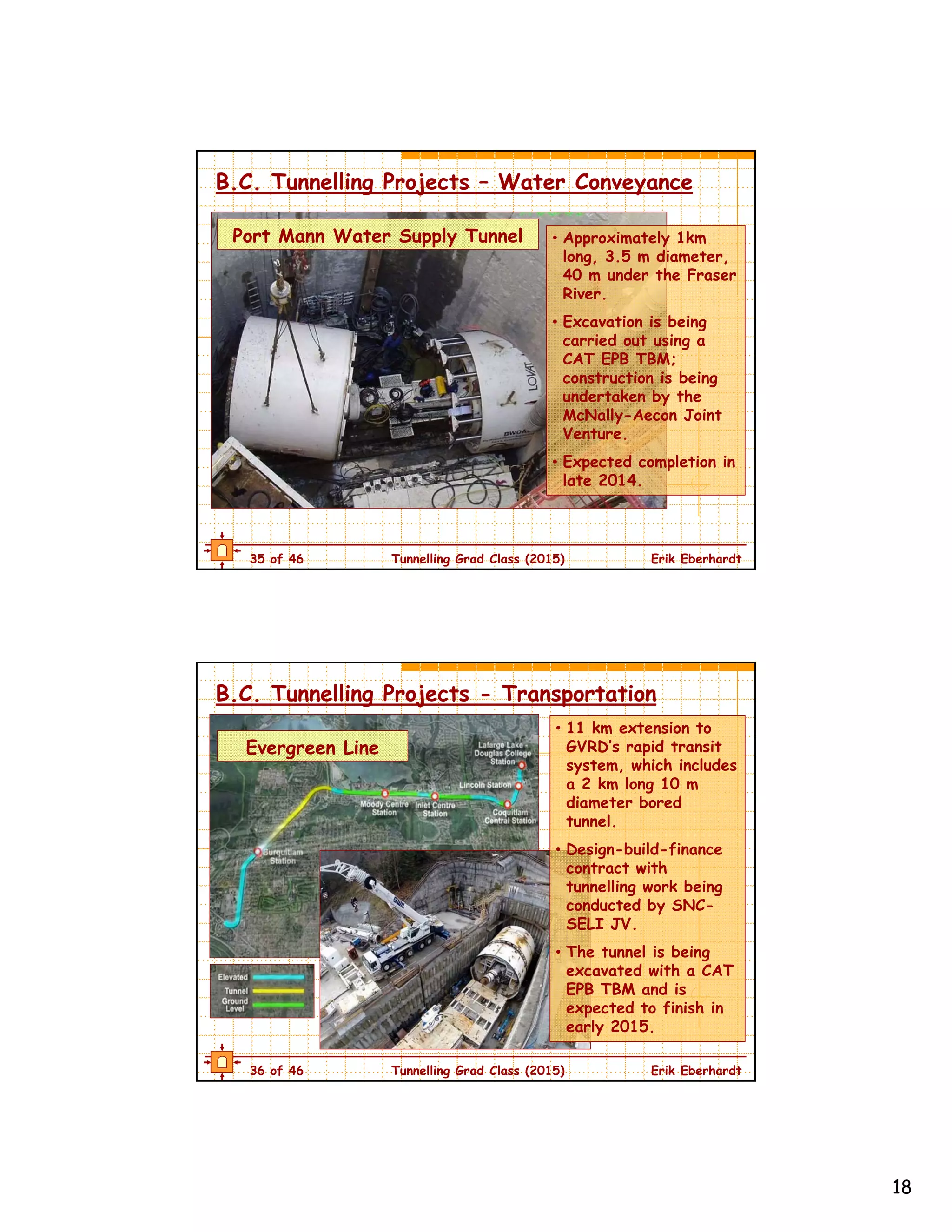

This document provides an overview of past and present tunnelling projects and challenges. It discusses the stuck Bertha tunnel boring machine in Seattle which has been stuck since 2013 due to overheating. It also discusses cost overruns and litigation on the Seymour-Capilano Twin Tunnels project in BC. Finally, it provides details on the course topics, lectures, and assignments for an introduction to tunnelling class.