This document provides terminology and descriptions related to underground structures like tunnels. It includes definitions of different tunnel construction elements and methods. Some key points covered include:

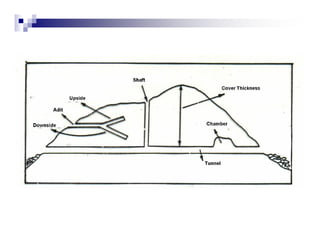

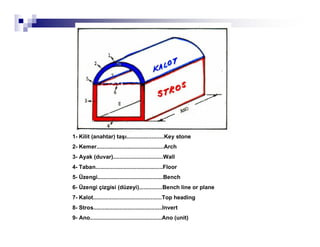

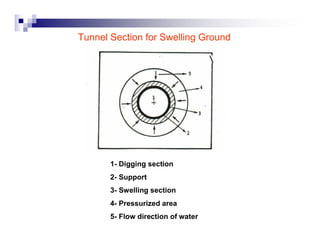

- Definitions of tunnel construction terms like adit, shaft, chamber, support, failure modes, and tunnelling methods.

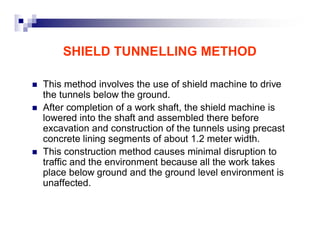

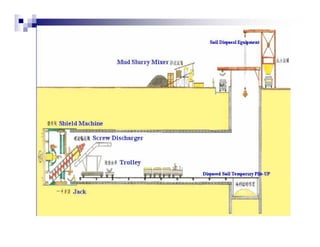

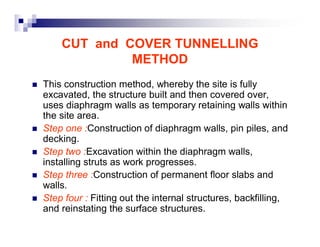

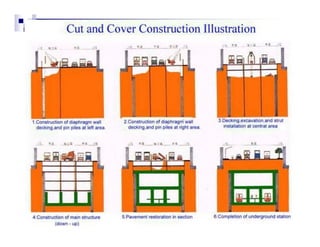

- Descriptions of different tunnelling methods including shield tunnelling, cut-and-cover tunnelling, and tunnelling boring machines (TBMs).

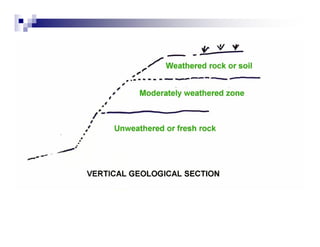

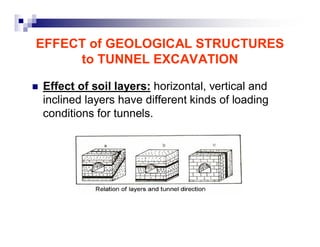

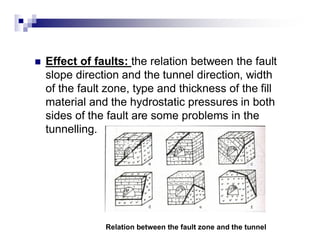

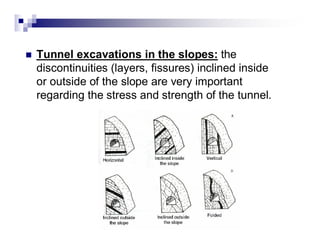

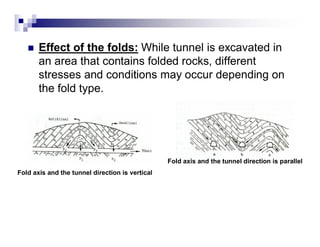

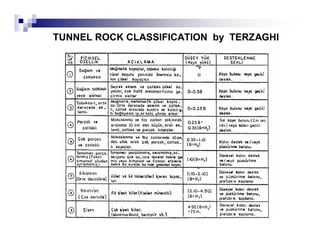

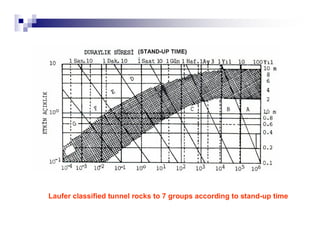

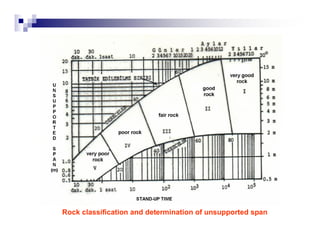

- Factors that influence rock excavation for tunnels like geological structures, rock properties, and resistance to excavation.

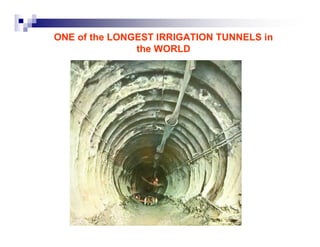

- Examples of large irrigation tunnels including details of the Urfa Irrigation Tunnel in Turkey.