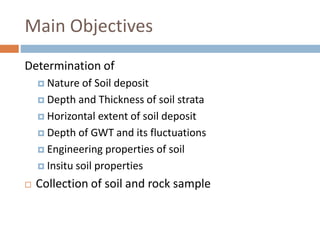

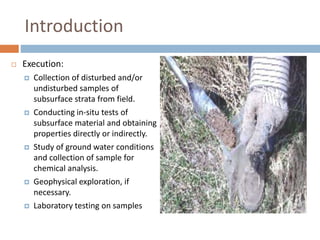

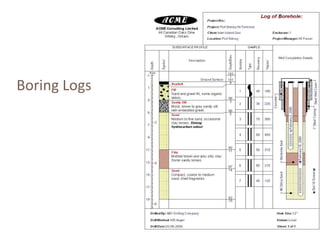

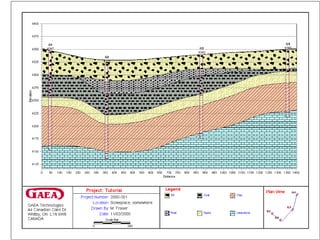

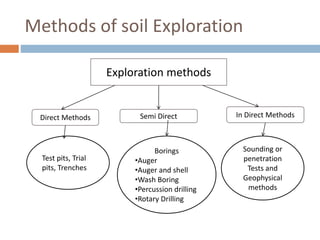

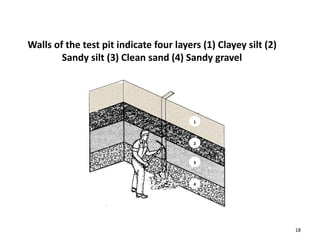

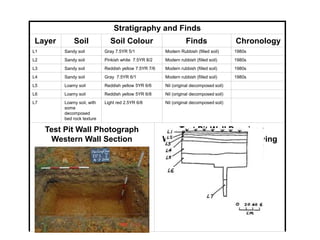

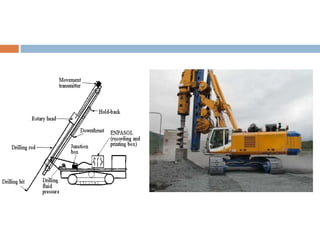

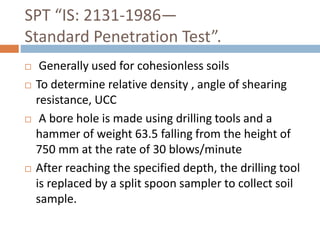

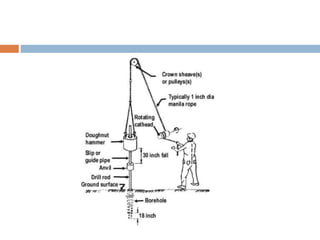

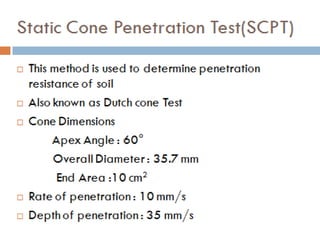

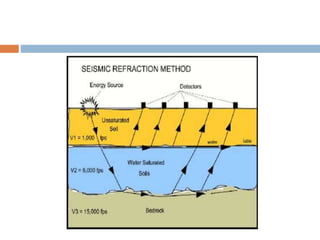

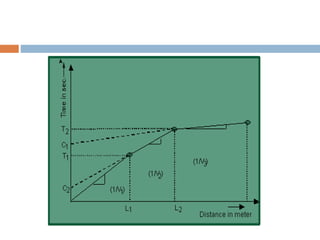

Subsoil exploration involves collecting soil data through field and laboratory investigations to assess soil properties at a site. The main objectives are to determine the nature, depth, thickness, and extent of soil strata as well as groundwater conditions and engineering properties. Methods include test pits, borings using augers or drilling, in-situ tests like SPT and CPT, and geophysical methods. Proper planning, execution, and reporting of the investigation are needed to provide reliable data to aid foundation design.