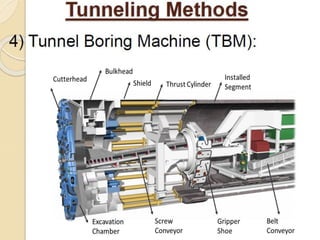

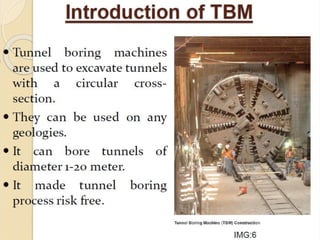

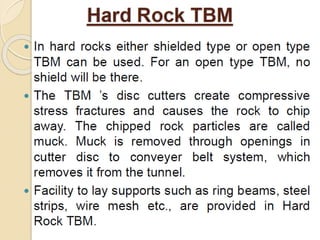

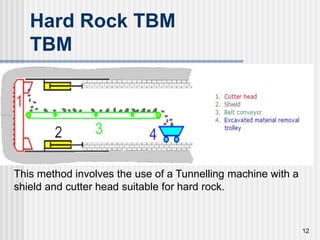

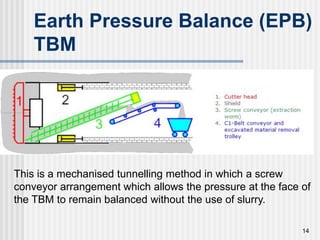

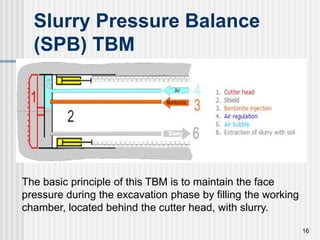

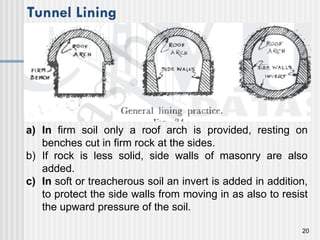

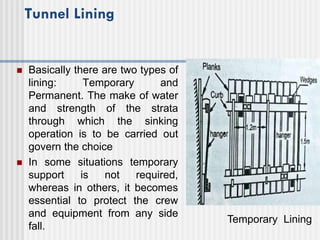

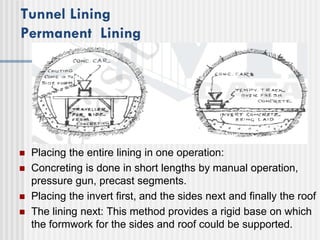

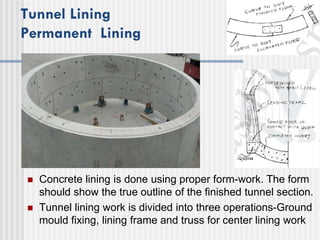

A tunnel boring machine (TBM) is used to excavate circular tunnels through various soil and rock strata. TBMs can excavate tunnels from 1 to nearly 20 meters in diameter. They are used as an alternative to drilling and blasting or conventional hand mining, and produce a smooth tunnel wall that reduces construction costs. There are several types of TBMs suited to different ground conditions, including hard rock TBMs, earth pressure balance machines, and slurry pressure balance machines. Tunnel lining involves installing temporary supports during excavation and permanent brick, stone, timber or concrete structures after excavation to support the tunnel walls and prevent collapse or water ingress.