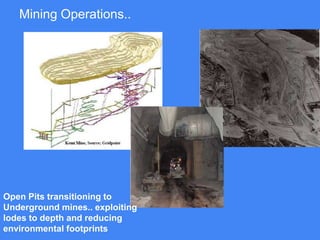

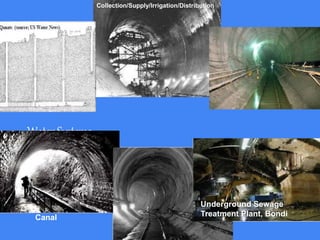

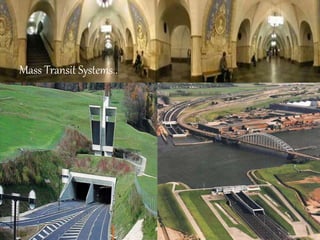

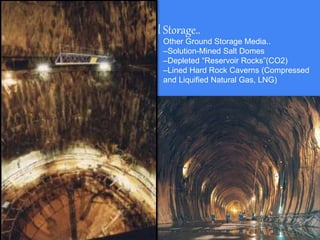

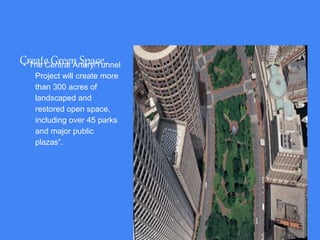

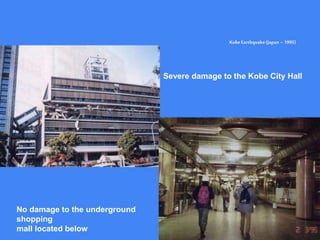

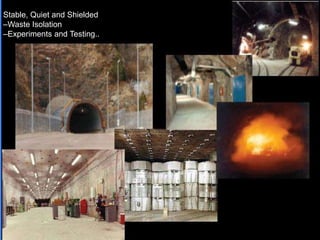

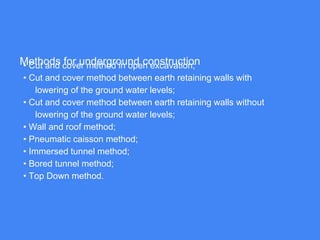

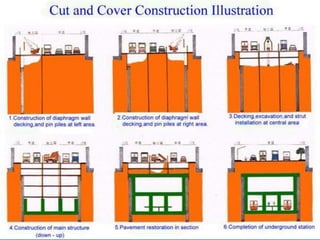

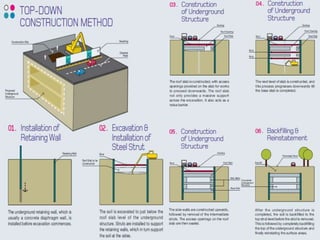

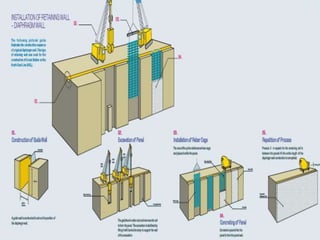

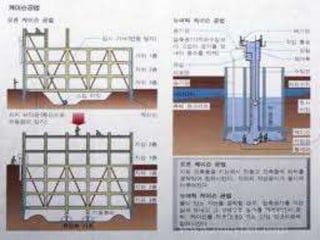

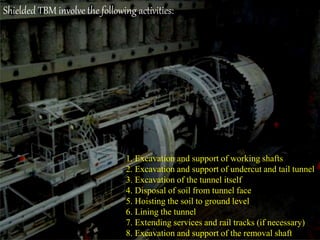

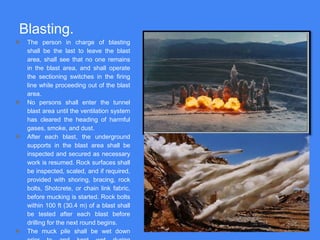

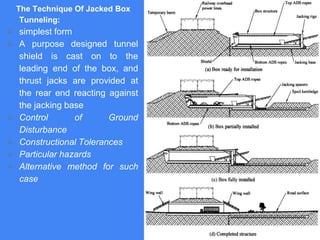

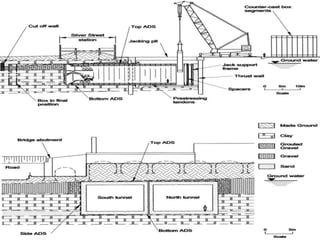

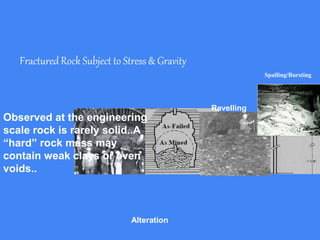

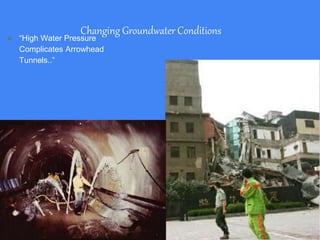

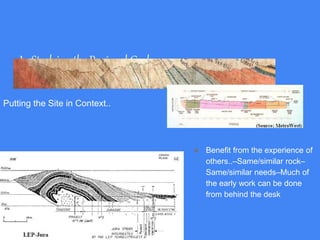

The document outlines the various aspects of underground construction, including the reasons for going underground, methods of construction, and the challenges encountered. It highlights the benefits such as reduced urban congestion, the creation of safe spaces, and the use of underground facilities for storage, infrastructure, and research. Risk management strategies and the importance of collaboration between practitioners and researchers are emphasized to mitigate potential issues during underground operations.