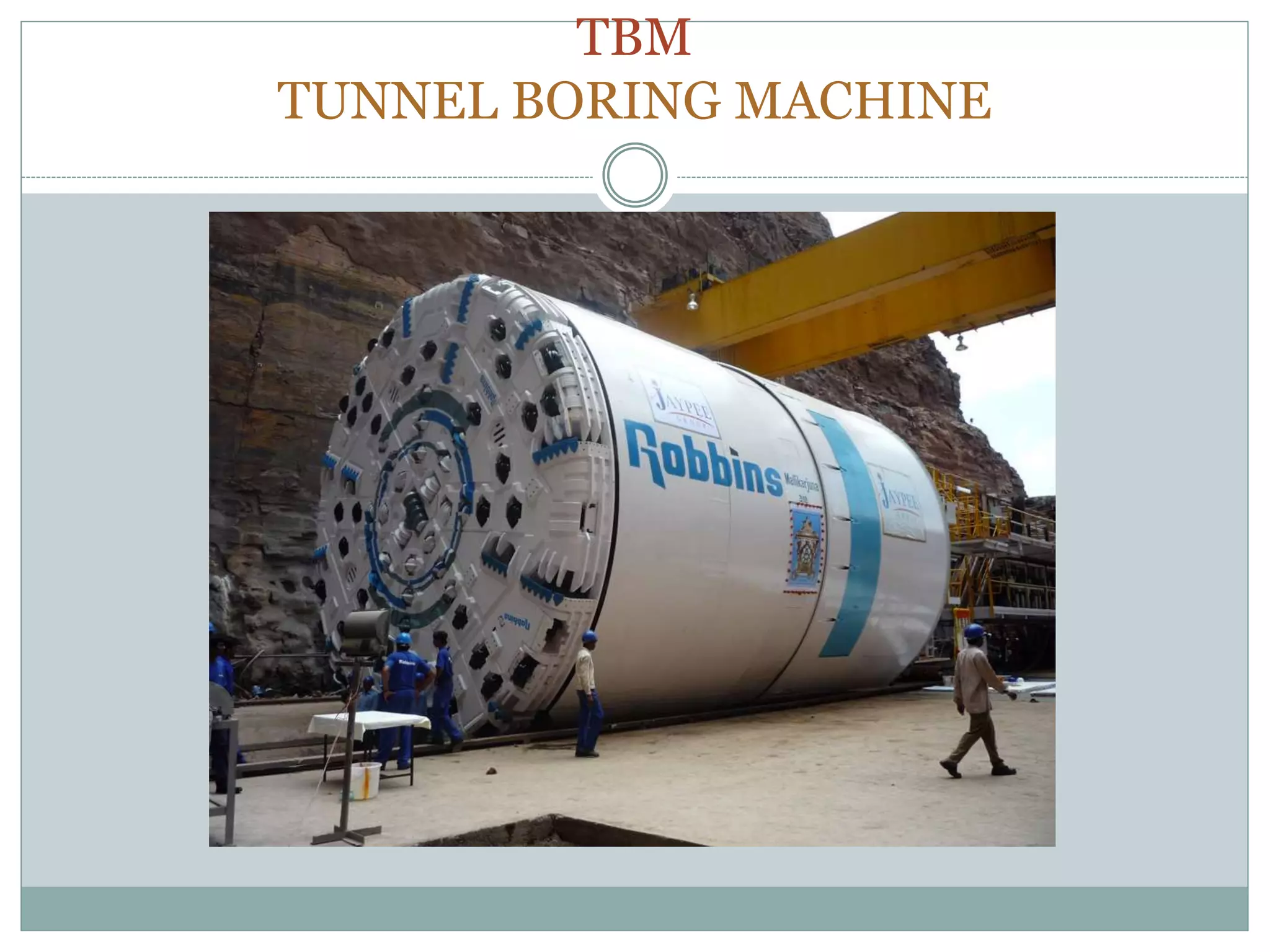

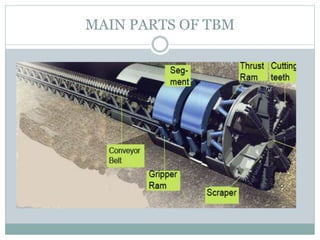

Tunnel boring machines (TBMs) are specialized machines used to excavate tunnels with a circular cross-section through various soil and rock types, offering advantages like higher advance rates and greater worker safety. Historically, TBMs have evolved from the early drilling and blasting methods, showcasing significant benefits over traditional techniques, although they have notable disadvantages such as high upfront costs and transportation difficulty. Applications for TBMs include transportation systems, sewers, mining, and hydroelectric projects, emphasizing their importance in providing safer environments for workers.