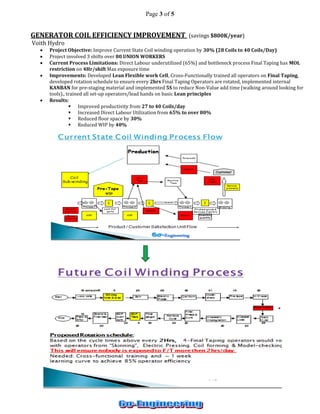

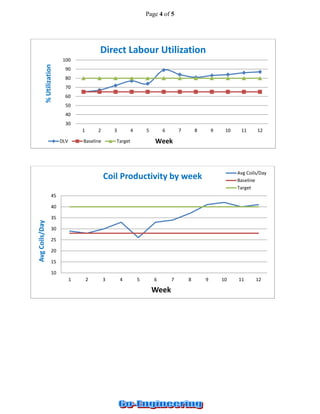

This document describes several Lean Six Sigma projects aimed at improving efficiency and reducing costs. It summarizes multiple projects including reducing packaging scrap, improving productivity in packaging and coil winding operations, reducing injection molding setup times, and implementing a warehouse management system. One project improved productivity from 240 to 331 packs per hour and reduced setup time from 30 minutes to under 5 minutes, realizing annual savings of $300,000.