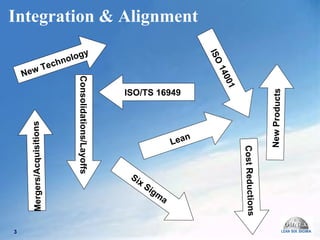

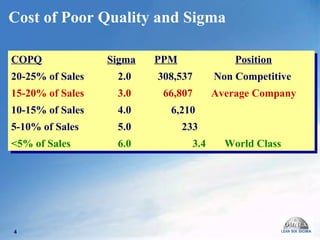

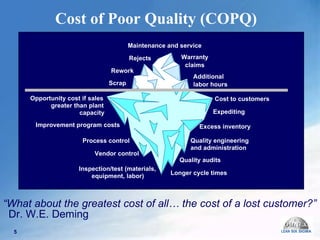

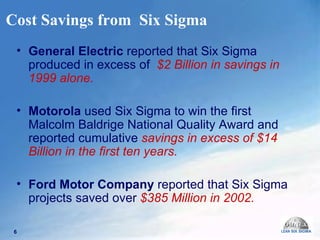

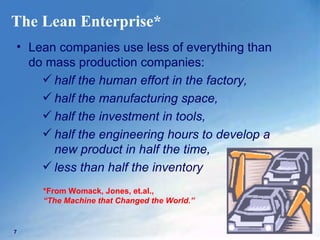

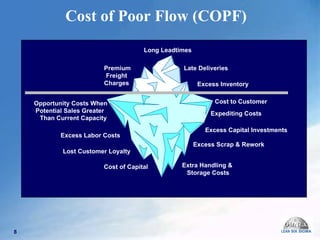

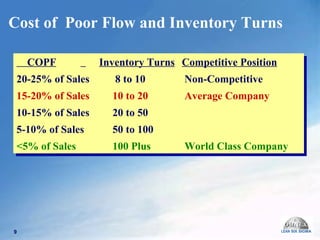

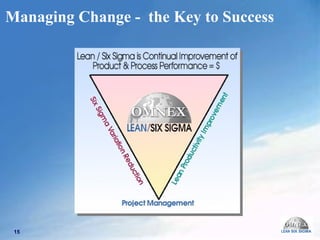

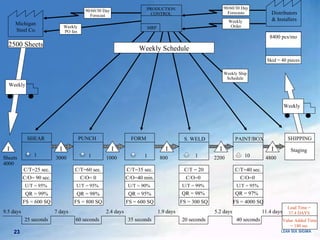

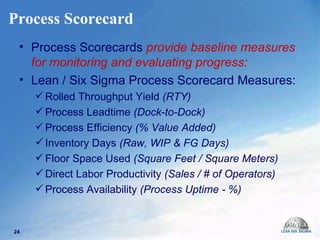

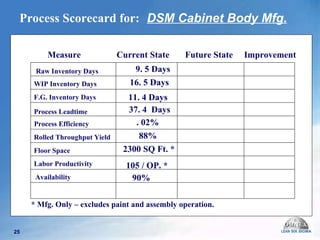

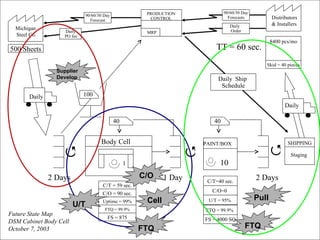

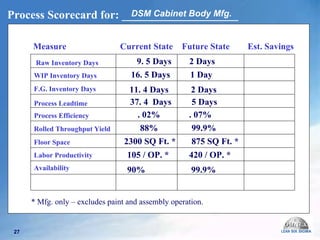

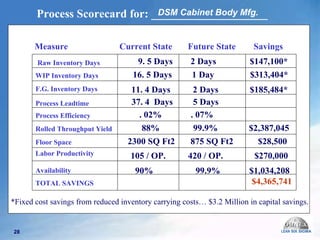

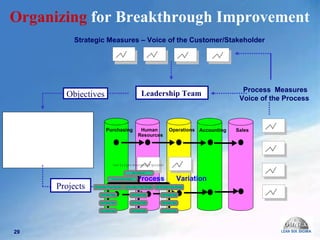

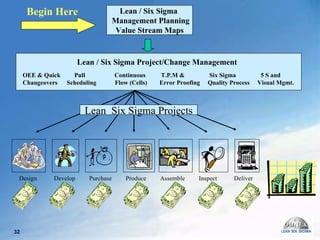

This document discusses integrating Lean and Six Sigma approaches to achieve breakthrough improvements in quality, productivity, and competitive position. It outlines key metrics like cost of poor quality, process lead times, inventory turns, and process efficiency that can be improved. Value stream mapping is presented as a tool to identify improvement opportunities and track progress. Linked scorecards are proposed to monitor performance across key areas like profits, products, processes, projects and people.