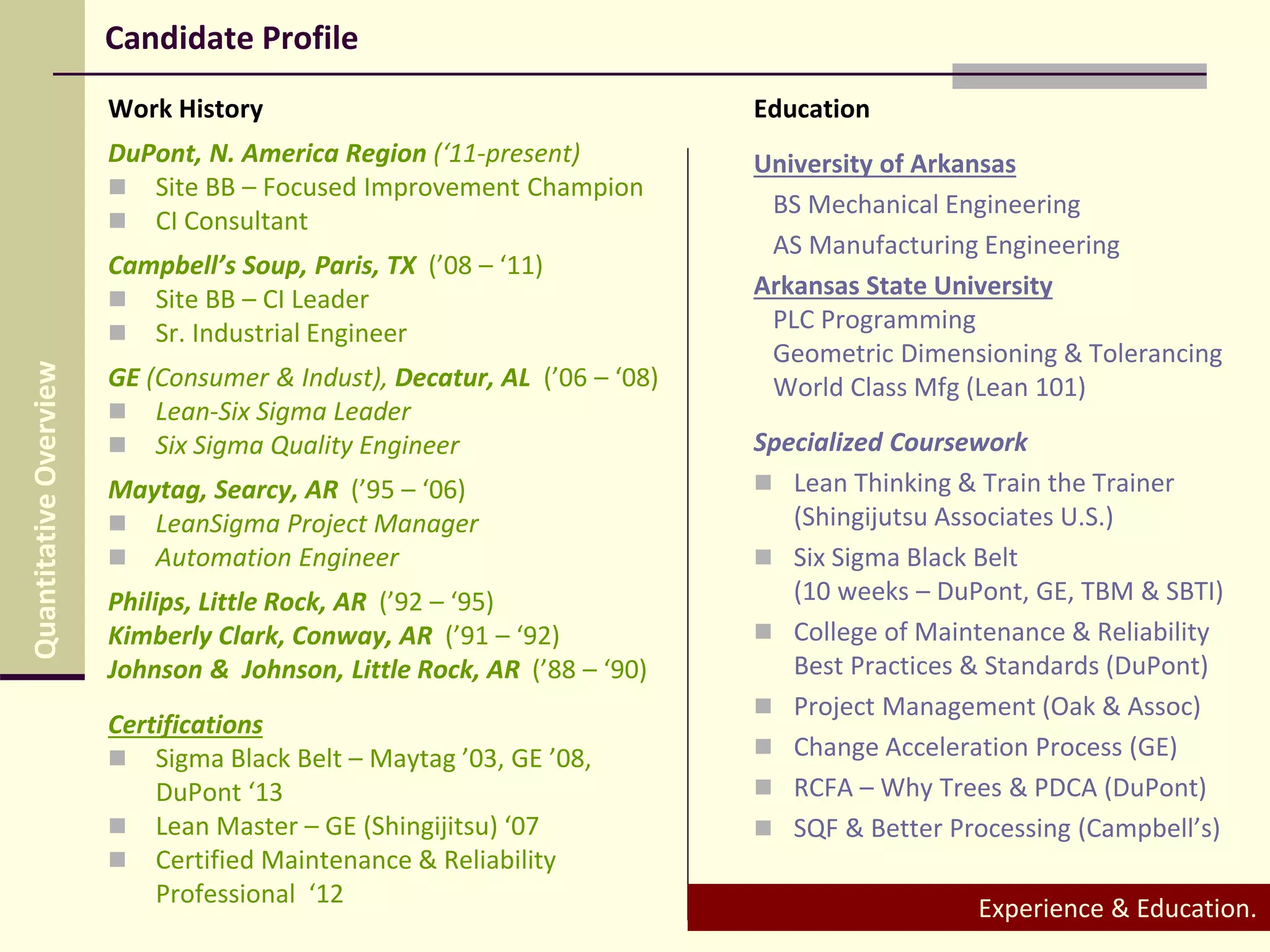

This document provides a summary of a candidate's work history and qualifications. It shows that they have over 25 years of experience leading continuous improvement initiatives in operations management, process engineering, and reliability engineering roles in various industries. They specialize in Lean Six Sigma and have a track record of delivering measurable results through process improvement projects. Their experience and certifications qualify them to develop strategic visions, execute improvement plans, train others, and drive results through problem-solving leadership.

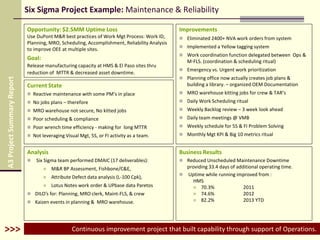

![Lean Example: Searcy Laundry Production

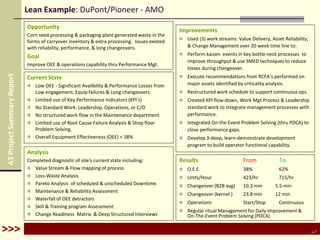

Opportunity

Transformation of ‘batch and queue’ manufacturing into a ‘build

to order; takt time driven’ organization

Goal

Build organization unified in daily improvement of metrics

Improvements

Performed relentless kaizen activity throughout site.

Trained workforce & changed culture to CI mentality

Lines & Fab Cells renovated

Visually managed areas (weekly 5S audits)

Takt-driven; cycle times, replenish & crewing

Min-max pull systems for materials

Standardized Work for ops & supervisors

Synchronized delivery from O/H’s & FT’s

Implemented countless error-proof devices

Current State

Long assembly lines – too much inventory on line

Overproduction of parts – All parts pushed to assembly

No visual management (5S)– no operator standard work

Long production runs & arduous changeovers

Line balance tied to forecast – not customer demand

Wastes prevalent in all (7) TIM WOOD categories

Associates not engaged in problem resolution & kaizen

Results

Cleared workspace; 64% white space in Assembly

Reduced assembly line length by 47%,

Reduced OSHA Rate 28% plant wide,

Improved FP Yield 91% to 98%,

RTY from 35% to 85%

Reduced in plant Lead time by 62%,

Productivity: 1.42 (Hr/unit) to <1.0 in 3yrs [68%],

Shortened New Product Introduction time [30%]

Reduce Service Call Rate 4.2 calls/1000 to 1.7/1000

Analysis

VSM drawn and VA / NVA ratio analysis completed

Opportunities cited for following kaizen event activities

Shop floor cellular breakthrough (12)

Material flow; Kanban & SMED (4)

Visual-Quality improvement (5S & Poka Yoke)

3P; Design for Manufacturability (3)

Management system & Employee empowerment studies

A3ProjectSummaryReport

Lean enterprise transformation is about seeing the whole while working on individual parts.>>>](https://image.slidesharecdn.com/20f1fb49-24ae-4abc-ae5c-e575a78306a7-150423083558-conversion-gate02/85/Candidate-Profile-DW-2015-3-320.jpg)