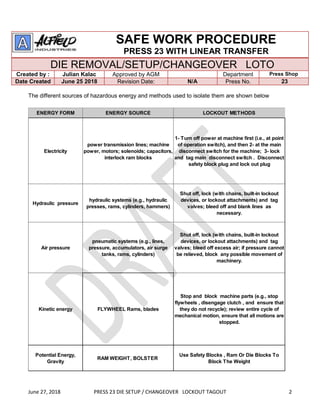

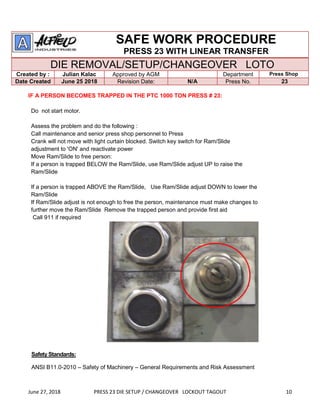

This document outlines lockout/tagout procedures for die setup and changeover on Press 23. It describes shutting down and locking out the various energy sources on the press, including the flywheel, hydraulic systems, and electrical power. Safety blocks must be used any time work is done between the slide and bolster to support the static load and prevent accidental press activation. The procedures are designed to achieve a zero energy state and protect workers during die work.